If you’ve driven along the M7 recently, you may have spotted a major construction project just outside Monasterevin, Kildare. The series of large tanks with bubble-like domes is hard to miss.

This is Ireland’s first new, modern anaerobic digestion (AD) plant. It is being developed by the Irish company Evergreen Agricultural Enterprises and aims to be producing biomethane by next year. The Irish Farmers Journal recently visited the site to learn more.

Patrick Meade and Katarzyna Kubizna.

Background

With a background in the logistics, quarry, and aggregate recycling industry, Patrick Meade, managing director of Evergreen Agricultural Enterprises has previously been involved with plans for anaerobic digestion plants back in 2010 which didn’t materialise.

When we visited the busy construction site, Patrick, and his business partner and financial director Katarzyna Kubizna explained that, despite being a slow burner, they still saw the potential of AD in Ireland.

Hot water will circulate through the tanks via pipes, and each tank has three long-arm mixers and three submersible mixers.

When the 20ac site outside Monasterevin came up for sale in 2021, they saw it as ideal for an AD plant and launched the Evergreen Agricultural Enterprises project.

Their previous experience taught them that choosing the right site was critical. This one ticked all the boxes; it is just off the M7 for easy access, well away from homes, bordered by a rail line to limit future housing, located in an agricultural area and only 20m from the national gas network.

The view from inside the tank where gas will be collected under the dome covers, then cleaned and purified.

The plant

When we visited, the site was a hive of activity. Planning permission was secured in 2023, and construction of the tanks began in March of this year. The plan includes four primary digesters and one secondary, each with a volume of 4,300m³.

The tanks are made from stainless steel. Hot water will circulate through the tanks via pipes, heating them to 36°C. An on-site combined heat and power (CHP) plant will generate about 1MW of electricity to run the facility and provide all heat for the tanks. The CHP will run on biogas from the AD plant. The plant will also have three liquid feedstock storage tanks.

External cladding has been installed on some of the tanks.

Each tank has a volume of 4,300m³.

Digestate will be stored in a covered concrete lagoon. Feedstock will be delivered to a reception building, where digestate will also be separated. Offices, the control room and a toolshed will also be located there. Silage clamps will be located beside the building.

Each tank has three long-arm mixers and three submersible mixers, sufficient to keep the mostly liquid feedstock moving. Gas will be collected under the dome covers, then cleaned and purified.

The biomethane gas will then be spiked and injected directly into the gas network, which runs adjacent to the plant. The plant will produce around 1,200m3 of biomethane gas each hour, which equates to around 100GWh of energy.

The shed roof was being installed on the day of the visit.

Construction in progress at Evergreen Agricultural Enterprises Ltd, Co. Kildare.

German firm Weltec Biopower is building the plant, and Patrick explained they were, in part, chosen for their fast delivery timeframe. Weltec will build and commission the plant before handover. Most of the civil works are being done by local companies.

Feedstock

Patrick and Katarzyna said they deliberately chose not to target waste feedstocks, which often concern local communities, and instead opted for materials not classified as waste. A key goal was to support a circular economy in agriculture, so they focused on residues and byproducts from Ireland’s beer and whiskey industry, mostly unsuitable for animal feed and widely available.

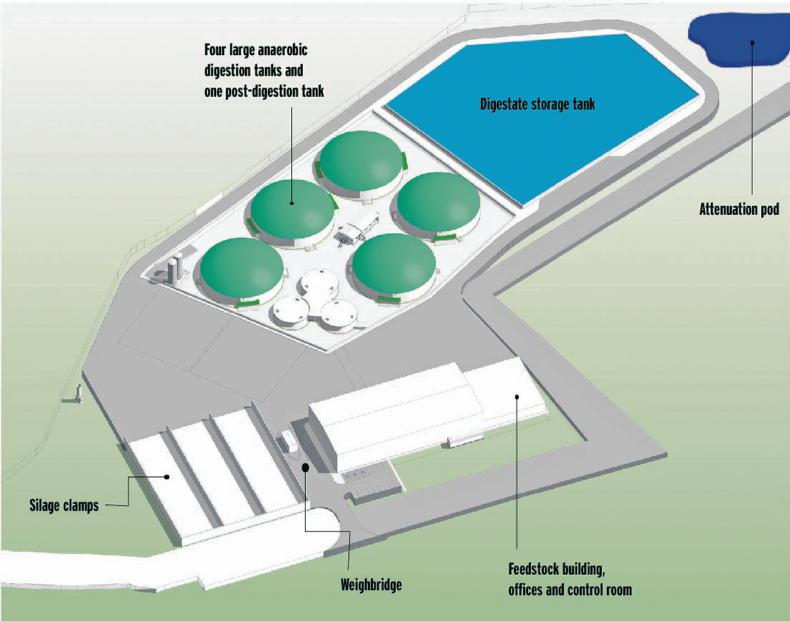

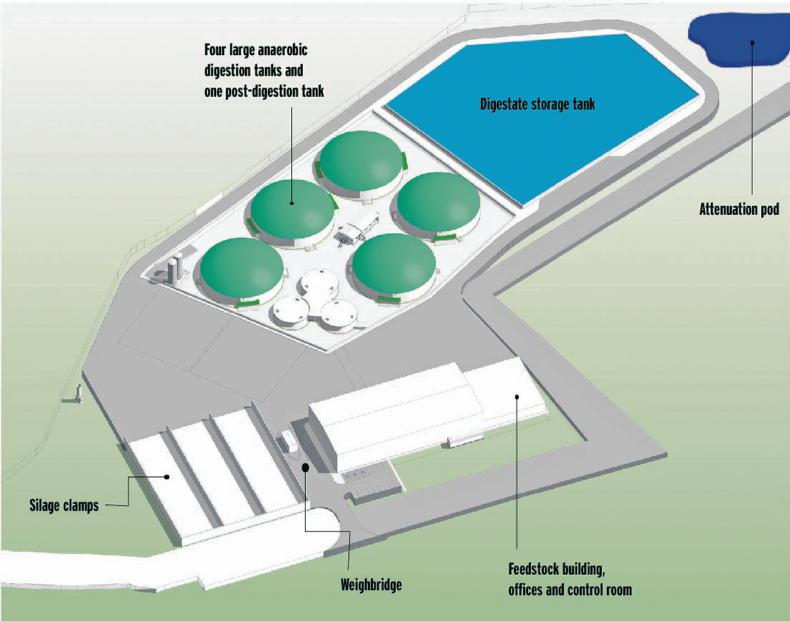

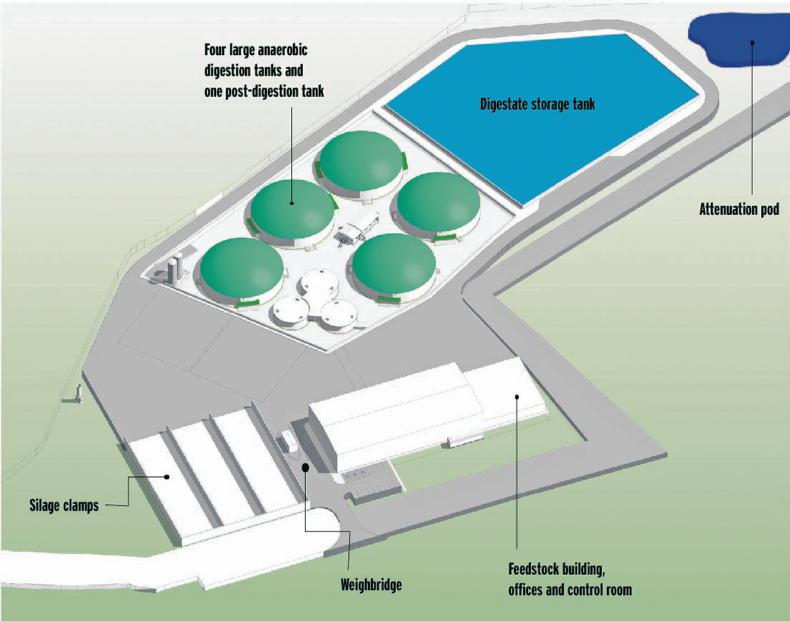

The layout of the site.

Although the plant has permission to process 165,000t, they are initially limiting it to 100,000t, allowing feedstock to stay in the tanks for about 84 days. Byproducts will be sourced from the drinks industry, some purchased and others accepted for a gate fee.

They also made a conscious effort to stay away from grass silage, as he didn’t want to compete with the livestock industry. Instead, they will also be using around 15,000t of maize silage and 10,000t cereal straw, which will be bought from local tillage farmers and businesses.

The plant is located between the M7 motorway and the railway line.

Work was starting on the first liquid feedstock reception tank.

Digestate

Once fully operational, the plant will produce about 80,000t of digestate annually, which will be sold to local farmers. A consultant has been hired to manage nutrient management plans.

The digestate will be separated on-site into liquid and solid fractions and delivered to lead farmers with sufficient storage and demand. Patrick said they may help fund extra storage if required. Lead farmers will use the digestate as fertiliser and may also supply smaller farms.

The company’s new AD plant is taking shape.

Ongoing testing will determine the expected NPK content of the digestate, with full nutrient profiles available for each load from 2027. This plant may be the only one on the island not using waste, slurry or manure, meaning its digestate does not require pasteurisation, a major economic advantage. However, that means the plant must be started from cold without seed digestate, taking about six months to ramp up fully.

The tanks each have 100mm insulation (blue).

Over 4,000 piles were inserted on the site.

The fifth tank, and the three feedstock reception tanks have yet to be built.

Finance and offtake

At the time of the visit, the project was three weeks ahead of schedule. Work was beginning on the fifth tank, the shed roof was being installed, and construction of the feedstock clamps and concrete lagoon was about to start. The goal is to cold-commission the plant by year end and produce gas by next summer, a very tight timeline driven by the conditions of the 20% DAFM Biomethane Capital Grant Scheme.

Feedstock will be delivered to a reception building, where digestate will also be separated.

The covers are held in place with compressed air.

Cold commissioning essentially means the plant must be capable of producing gas. Considering construction only began in March, this is an exceptionally ambitious schedule, and most of the other 17 grant recipients are unlikely to meet it.

Financing for the €30+ million project is still being finalised, with the lack of a guaranteed gas market a key challenge, Patrick said.

The base of the tanks are also insulated.

One of the mixers in the tank.

The shed roof was being installed at the time of the visit.

Without a renewable heat obligation, mandating gas purchase, long-term offtake agreements are hard to secure. Patrick remains confident, however, with financing and offtake negotiations at an advanced stage he said.

Community acceptance

Patrick said reception to the project has been positive, with good local support. While several objections were received at the planning stage, only one appeal was lodged by An Lucht Inbhuanaithe, a self-styled environmental NGO whose serial objections were exposed in an RTÉ Investigates programme in 2022.

Hot water will circulate through the tanks via pipes, and each tank has three long-arm mixers and three submersible mixers.

The appeal was dropped soon after. He added that their aim is to integrate with the community, which is why they avoided waste and grass silage. Patrick believes that as more AD plants are built, the technology will become normalised in rural areas.

What is in it for farmers?

There are two key elements of the project that directly involve farmers, feedstock supply and digestate use.

The plant will produce a significant volume of digestate, estimated to require between 2,500ac and 5,000ac of land for spreading. The exact land requirement will be known once nutrient analysis is complete. Patrick plans to sell the digestate, with current indications suggesting a price of about €10/t plus delivery for the liquid fraction (around 65,000t annually) and about €50/t for the solid fraction (around 15,000t annually).

On the feedstock side, 700ac–800ac of wholecrop maize will be required each year, sourced from local tillage farmers. Contracts are planned, though the final structure is still being developed. Patrick acknowledged farmers’ concerns over long-term contracts and said a pricing mechanism that tracks market and input costs will be needed to protect both sides.

Roughly one-third of the maize will be stored on-site, with the remainder stored on the farms. He thinks that using maize will create new markets for the tillage sector, which is facing significant challenges. The plant will employ 18 full-time staff directly, alongside supporting contractors and farmers.

If you’ve driven along the M7 recently, you may have spotted a major construction project just outside Monasterevin, Kildare. The series of large tanks with bubble-like domes is hard to miss.

This is Ireland’s first new, modern anaerobic digestion (AD) plant. It is being developed by the Irish company Evergreen Agricultural Enterprises and aims to be producing biomethane by next year. The Irish Farmers Journal recently visited the site to learn more.

Patrick Meade and Katarzyna Kubizna.

Background

With a background in the logistics, quarry, and aggregate recycling industry, Patrick Meade, managing director of Evergreen Agricultural Enterprises has previously been involved with plans for anaerobic digestion plants back in 2010 which didn’t materialise.

When we visited the busy construction site, Patrick, and his business partner and financial director Katarzyna Kubizna explained that, despite being a slow burner, they still saw the potential of AD in Ireland.

Hot water will circulate through the tanks via pipes, and each tank has three long-arm mixers and three submersible mixers.

When the 20ac site outside Monasterevin came up for sale in 2021, they saw it as ideal for an AD plant and launched the Evergreen Agricultural Enterprises project.

Their previous experience taught them that choosing the right site was critical. This one ticked all the boxes; it is just off the M7 for easy access, well away from homes, bordered by a rail line to limit future housing, located in an agricultural area and only 20m from the national gas network.

The view from inside the tank where gas will be collected under the dome covers, then cleaned and purified.

The plant

When we visited, the site was a hive of activity. Planning permission was secured in 2023, and construction of the tanks began in March of this year. The plan includes four primary digesters and one secondary, each with a volume of 4,300m³.

The tanks are made from stainless steel. Hot water will circulate through the tanks via pipes, heating them to 36°C. An on-site combined heat and power (CHP) plant will generate about 1MW of electricity to run the facility and provide all heat for the tanks. The CHP will run on biogas from the AD plant. The plant will also have three liquid feedstock storage tanks.

External cladding has been installed on some of the tanks.

Each tank has a volume of 4,300m³.

Digestate will be stored in a covered concrete lagoon. Feedstock will be delivered to a reception building, where digestate will also be separated. Offices, the control room and a toolshed will also be located there. Silage clamps will be located beside the building.

Each tank has three long-arm mixers and three submersible mixers, sufficient to keep the mostly liquid feedstock moving. Gas will be collected under the dome covers, then cleaned and purified.

The biomethane gas will then be spiked and injected directly into the gas network, which runs adjacent to the plant. The plant will produce around 1,200m3 of biomethane gas each hour, which equates to around 100GWh of energy.

The shed roof was being installed on the day of the visit.

Construction in progress at Evergreen Agricultural Enterprises Ltd, Co. Kildare.

German firm Weltec Biopower is building the plant, and Patrick explained they were, in part, chosen for their fast delivery timeframe. Weltec will build and commission the plant before handover. Most of the civil works are being done by local companies.

Feedstock

Patrick and Katarzyna said they deliberately chose not to target waste feedstocks, which often concern local communities, and instead opted for materials not classified as waste. A key goal was to support a circular economy in agriculture, so they focused on residues and byproducts from Ireland’s beer and whiskey industry, mostly unsuitable for animal feed and widely available.

The layout of the site.

Although the plant has permission to process 165,000t, they are initially limiting it to 100,000t, allowing feedstock to stay in the tanks for about 84 days. Byproducts will be sourced from the drinks industry, some purchased and others accepted for a gate fee.

They also made a conscious effort to stay away from grass silage, as he didn’t want to compete with the livestock industry. Instead, they will also be using around 15,000t of maize silage and 10,000t cereal straw, which will be bought from local tillage farmers and businesses.

The plant is located between the M7 motorway and the railway line.

Work was starting on the first liquid feedstock reception tank.

Digestate

Once fully operational, the plant will produce about 80,000t of digestate annually, which will be sold to local farmers. A consultant has been hired to manage nutrient management plans.

The digestate will be separated on-site into liquid and solid fractions and delivered to lead farmers with sufficient storage and demand. Patrick said they may help fund extra storage if required. Lead farmers will use the digestate as fertiliser and may also supply smaller farms.

The company’s new AD plant is taking shape.

Ongoing testing will determine the expected NPK content of the digestate, with full nutrient profiles available for each load from 2027. This plant may be the only one on the island not using waste, slurry or manure, meaning its digestate does not require pasteurisation, a major economic advantage. However, that means the plant must be started from cold without seed digestate, taking about six months to ramp up fully.

The tanks each have 100mm insulation (blue).

Over 4,000 piles were inserted on the site.

The fifth tank, and the three feedstock reception tanks have yet to be built.

Finance and offtake

At the time of the visit, the project was three weeks ahead of schedule. Work was beginning on the fifth tank, the shed roof was being installed, and construction of the feedstock clamps and concrete lagoon was about to start. The goal is to cold-commission the plant by year end and produce gas by next summer, a very tight timeline driven by the conditions of the 20% DAFM Biomethane Capital Grant Scheme.

Feedstock will be delivered to a reception building, where digestate will also be separated.

The covers are held in place with compressed air.

Cold commissioning essentially means the plant must be capable of producing gas. Considering construction only began in March, this is an exceptionally ambitious schedule, and most of the other 17 grant recipients are unlikely to meet it.

Financing for the €30+ million project is still being finalised, with the lack of a guaranteed gas market a key challenge, Patrick said.

The base of the tanks are also insulated.

One of the mixers in the tank.

The shed roof was being installed at the time of the visit.

Without a renewable heat obligation, mandating gas purchase, long-term offtake agreements are hard to secure. Patrick remains confident, however, with financing and offtake negotiations at an advanced stage he said.

Community acceptance

Patrick said reception to the project has been positive, with good local support. While several objections were received at the planning stage, only one appeal was lodged by An Lucht Inbhuanaithe, a self-styled environmental NGO whose serial objections were exposed in an RTÉ Investigates programme in 2022.

Hot water will circulate through the tanks via pipes, and each tank has three long-arm mixers and three submersible mixers.

The appeal was dropped soon after. He added that their aim is to integrate with the community, which is why they avoided waste and grass silage. Patrick believes that as more AD plants are built, the technology will become normalised in rural areas.

What is in it for farmers?

There are two key elements of the project that directly involve farmers, feedstock supply and digestate use.

The plant will produce a significant volume of digestate, estimated to require between 2,500ac and 5,000ac of land for spreading. The exact land requirement will be known once nutrient analysis is complete. Patrick plans to sell the digestate, with current indications suggesting a price of about €10/t plus delivery for the liquid fraction (around 65,000t annually) and about €50/t for the solid fraction (around 15,000t annually).

On the feedstock side, 700ac–800ac of wholecrop maize will be required each year, sourced from local tillage farmers. Contracts are planned, though the final structure is still being developed. Patrick acknowledged farmers’ concerns over long-term contracts and said a pricing mechanism that tracks market and input costs will be needed to protect both sides.

Roughly one-third of the maize will be stored on-site, with the remainder stored on the farms. He thinks that using maize will create new markets for the tillage sector, which is facing significant challenges. The plant will employ 18 full-time staff directly, alongside supporting contractors and farmers.

SHARING OPTIONS