The focus of Farm Safety Week 2018 is to encourage good practice in farm safety and demonstrate how a safety conscious environment decreases the risk of an accident occurring. Constant strides are being made towards improving farm safety with innovation. Some of the most recent examples come from third-level and second-level students across Ireland.

Corey Breen developed a slurry alarm to warn of high levels of toxic gas.

Slurry alarm

Corey Breen, who studies agricultural science in UCD, has designed a slurry alarm which detects dangerous levels of potentially lethal gas released during agitation.

The idea is that the alarm would detect slurry gas once it reached a certain threshold telling people it is not safe to enter the shed. The alarm would then turn off once the levels were safe again. “It would be ideal to protect outsiders and young children who may venture down to the farmyard,” said Corey.

PTO sensor

Paul Donegan of IT Tralee has designed a detection system to disengage PTO shafts from operation in times of danger.

Paul Donegan, who has worked with machinery for 40 years, designed a PTO sensor.

With an orange and a red sensor, once the operator enters the perimeters set by the sensors, the PTO will disengage and have to be started from the cab of the tractor again. Six deaths out of the 64 machinery-related fatalities were due to entanglement in PTO shafts.

Both Corey Breen and Paul Donegan are part of the annual ESB farm safety challenge. The winner of this year’s competition will be decided at the National Ploughing Championships. Second-level students took part in the student enterprise national final day in May of this year and several entries prioritised farm safety in their innovation.

Lift arm assist

Edward Daly, Matthew O’Sullivan and John O’Brien from Kilkenny have developed an adaption to the lift arms of tractors.

Lift arm assist creators Matthew O'Sullivan, Edward Daly and John O'Brien at this year's National Enterprise Awards.

A hydraulic ram replaces the adjustable stabiliser arms of the tractor. The ram is controlled by the spool valves in the tractor and can push the arms in and out to the desired width. It is both labour saving and more efficient, according to Edward Daly. “We got the inspiration from our experience on farms. With John being a dairy farmer with only one tractor, it was taking a lot of time to change implements.” The product is marketed as a safety and labour saving device. Lift arm assist was the winner of the intermediate national enterprise award 2018.

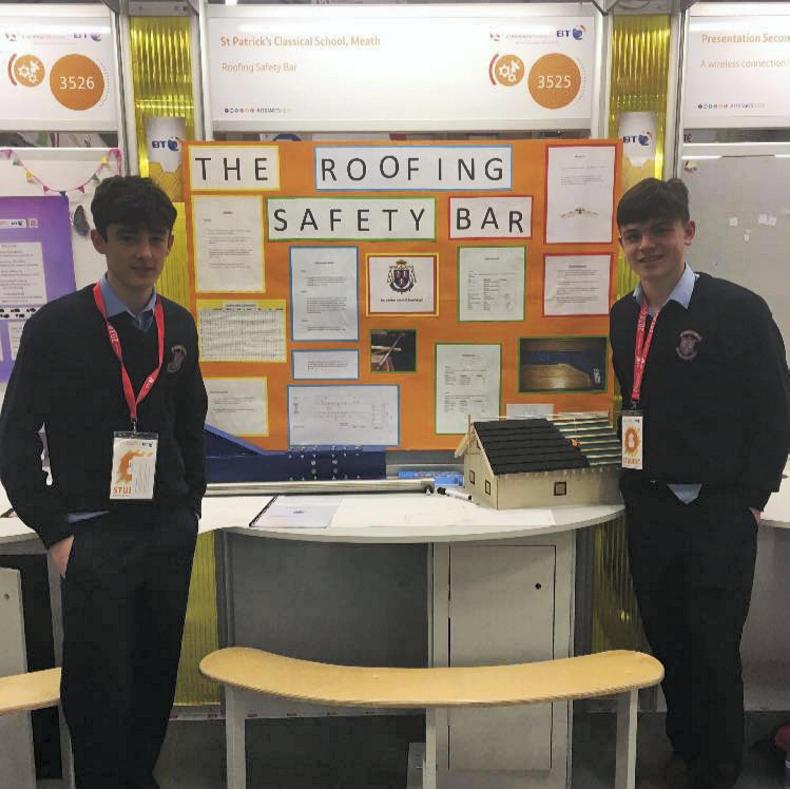

The roofing safety bar

The invention created by Darragh Canny and Sean Keogh of St Patrick’s Classical School in Navan allows roofers to work safely without restricting the capability for work.

A roofing safety bar developed by Sean Keogh and Darragh Canny aims to stop falls from roofs during work.

The user can slide along the roof while being safely attached to the roofing safety bar (RSB), which is clamped on to the gable ends of the structure.

Falling from heights accounts for a significant amount of deaths in the workplace. The inspiration for the idea came from the first-hand experience Darragh and Sean had from their construction and farming backgrounds. “We both had summer jobs involved in construction and agriculture. We saw the safety measures that exist but we realised once you go up on a scaffold you are incredibly vulnerable,” said Darragh. The RSB came second in the national enterprise awards and featured in the BT Young Scientist Award 2018. The product is patented and stress-tested by engineers.

Darragh pointed out the strong overlap between the construction and agricultural industries when it comes to falling from heights.

Reel Easy

Reel Easy is a product designed by students Shane Dobson, Shane Hagan, Daniel Doherty, Shane Grimes and Luke Horson of Moyne Community School in Co Longford.

Shane Hagan and Daniel Doherty with their product Reel Easy.

The device aims to save time and remove the stress from a tedious job. The device tensions wire or tape when transferring it from a spool to a reel.

According to Daniel Doherty, “the focus of the product is to turn the two-person job into a one-person job.”

The product can save time on a farm and when it comes to farm safety, slowing down and taking your time can save lives. Having young people as the ambassadors for farm safety is important if the number of fatalities are to come down.

The student enterprise programme is run by the Local Enterprise Office every year. More information about the products is available on www.studententerprise.ie.

The focus of Farm Safety Week 2018 is to encourage good practice in farm safety and demonstrate how a safety conscious environment decreases the risk of an accident occurring. Constant strides are being made towards improving farm safety with innovation. Some of the most recent examples come from third-level and second-level students across Ireland.

Corey Breen developed a slurry alarm to warn of high levels of toxic gas.

Slurry alarm

Corey Breen, who studies agricultural science in UCD, has designed a slurry alarm which detects dangerous levels of potentially lethal gas released during agitation.

The idea is that the alarm would detect slurry gas once it reached a certain threshold telling people it is not safe to enter the shed. The alarm would then turn off once the levels were safe again. “It would be ideal to protect outsiders and young children who may venture down to the farmyard,” said Corey.

PTO sensor

Paul Donegan of IT Tralee has designed a detection system to disengage PTO shafts from operation in times of danger.

Paul Donegan, who has worked with machinery for 40 years, designed a PTO sensor.

With an orange and a red sensor, once the operator enters the perimeters set by the sensors, the PTO will disengage and have to be started from the cab of the tractor again. Six deaths out of the 64 machinery-related fatalities were due to entanglement in PTO shafts.

Both Corey Breen and Paul Donegan are part of the annual ESB farm safety challenge. The winner of this year’s competition will be decided at the National Ploughing Championships. Second-level students took part in the student enterprise national final day in May of this year and several entries prioritised farm safety in their innovation.

Lift arm assist

Edward Daly, Matthew O’Sullivan and John O’Brien from Kilkenny have developed an adaption to the lift arms of tractors.

Lift arm assist creators Matthew O'Sullivan, Edward Daly and John O'Brien at this year's National Enterprise Awards.

A hydraulic ram replaces the adjustable stabiliser arms of the tractor. The ram is controlled by the spool valves in the tractor and can push the arms in and out to the desired width. It is both labour saving and more efficient, according to Edward Daly. “We got the inspiration from our experience on farms. With John being a dairy farmer with only one tractor, it was taking a lot of time to change implements.” The product is marketed as a safety and labour saving device. Lift arm assist was the winner of the intermediate national enterprise award 2018.

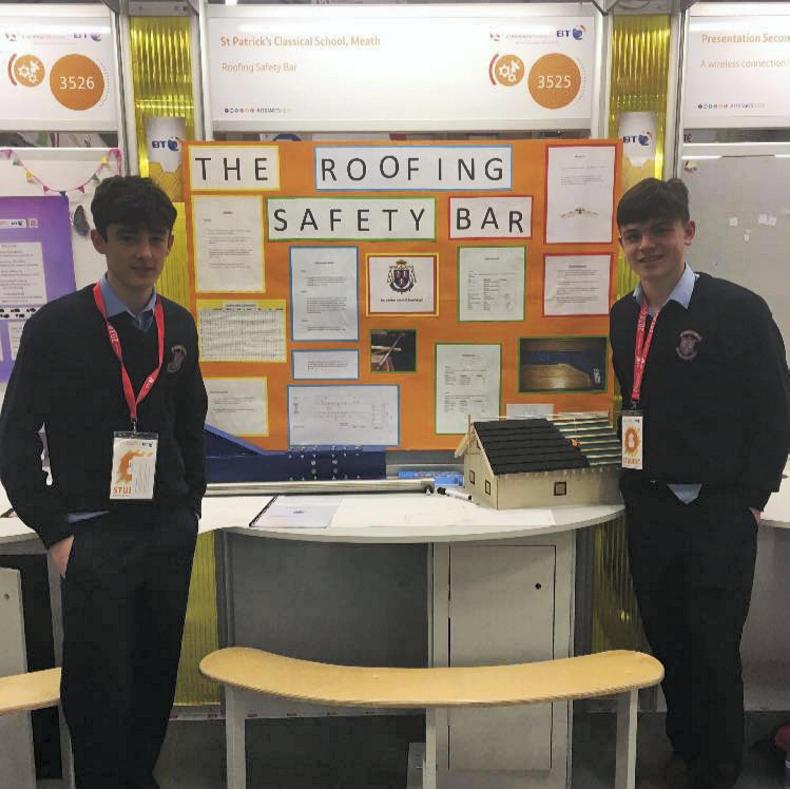

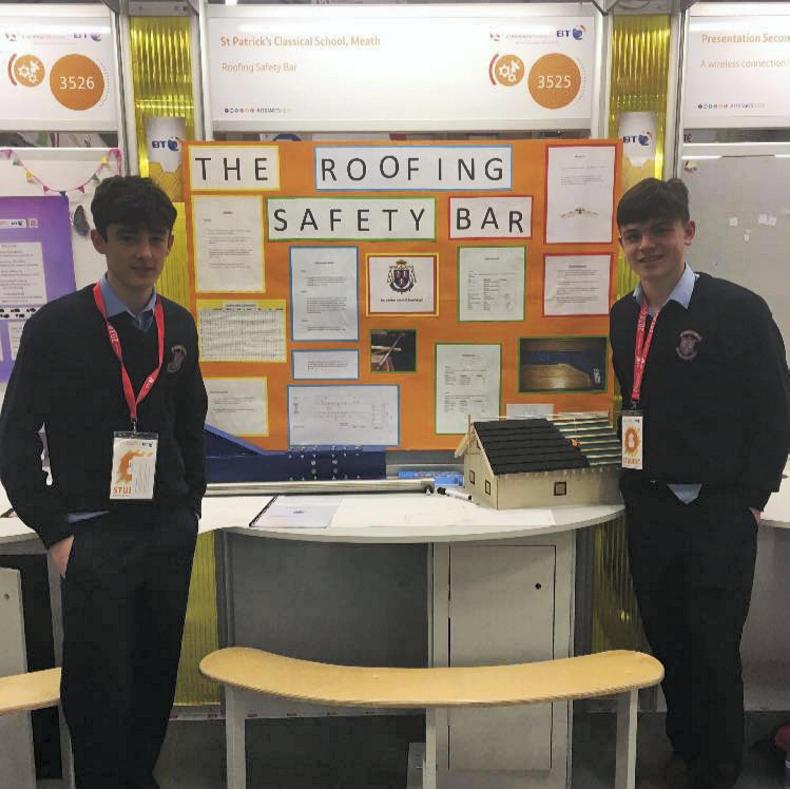

The roofing safety bar

The invention created by Darragh Canny and Sean Keogh of St Patrick’s Classical School in Navan allows roofers to work safely without restricting the capability for work.

A roofing safety bar developed by Sean Keogh and Darragh Canny aims to stop falls from roofs during work.

The user can slide along the roof while being safely attached to the roofing safety bar (RSB), which is clamped on to the gable ends of the structure.

Falling from heights accounts for a significant amount of deaths in the workplace. The inspiration for the idea came from the first-hand experience Darragh and Sean had from their construction and farming backgrounds. “We both had summer jobs involved in construction and agriculture. We saw the safety measures that exist but we realised once you go up on a scaffold you are incredibly vulnerable,” said Darragh. The RSB came second in the national enterprise awards and featured in the BT Young Scientist Award 2018. The product is patented and stress-tested by engineers.

Darragh pointed out the strong overlap between the construction and agricultural industries when it comes to falling from heights.

Reel Easy

Reel Easy is a product designed by students Shane Dobson, Shane Hagan, Daniel Doherty, Shane Grimes and Luke Horson of Moyne Community School in Co Longford.

Shane Hagan and Daniel Doherty with their product Reel Easy.

The device aims to save time and remove the stress from a tedious job. The device tensions wire or tape when transferring it from a spool to a reel.

According to Daniel Doherty, “the focus of the product is to turn the two-person job into a one-person job.”

The product can save time on a farm and when it comes to farm safety, slowing down and taking your time can save lives. Having young people as the ambassadors for farm safety is important if the number of fatalities are to come down.

The student enterprise programme is run by the Local Enterprise Office every year. More information about the products is available on www.studententerprise.ie.

SHARING OPTIONS