The labour input required on suckler-beef farms is heavily influenced by the farm’s infrastructure and handling facilities. This statement increases in importance where 100% artificial insemination is practiced. Nicholas Bergin’s family farm in Coolnagh, Roscrea, Co Tipperary, is operated by Nicholas and his wife Bernie, son Danny and daughter Carol.

Nicholas Bergin, Roscrea.

The 100-cow autumn-calving herd, which produces E- and U-grade weanlings, is run on a part-time basis, with Nicholas working with Dovea Genetics as an area representative covering Galway and Offaly. His role is busiest in the first six months of the year and as such, autumn-calving fits best, with calving commencing from the end of July onwards.

The main suckler shed on the farm was built over a decade ago and facilitates the farm’s breeding programme of 100% AI and optimising labour efficiency. Many of the elements included were captured through farm visits during Nicholas’s off-farm work, with much thought invested in planning its design.

The shed

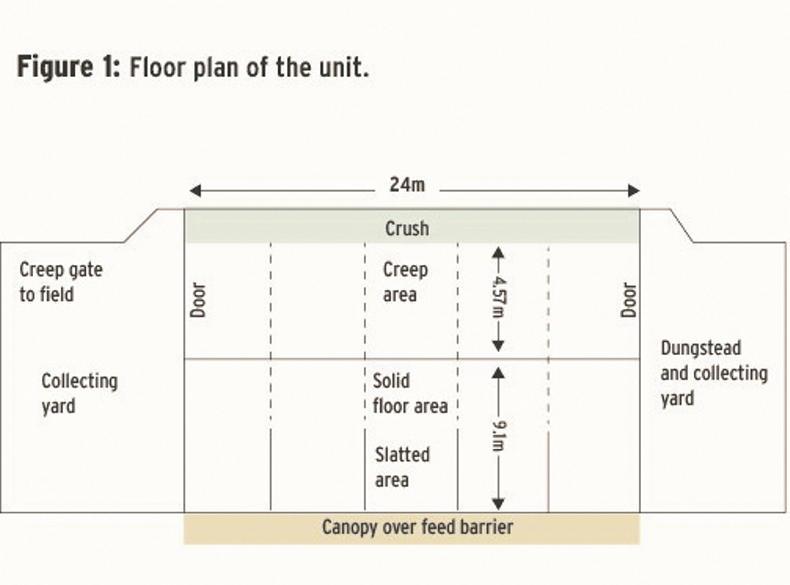

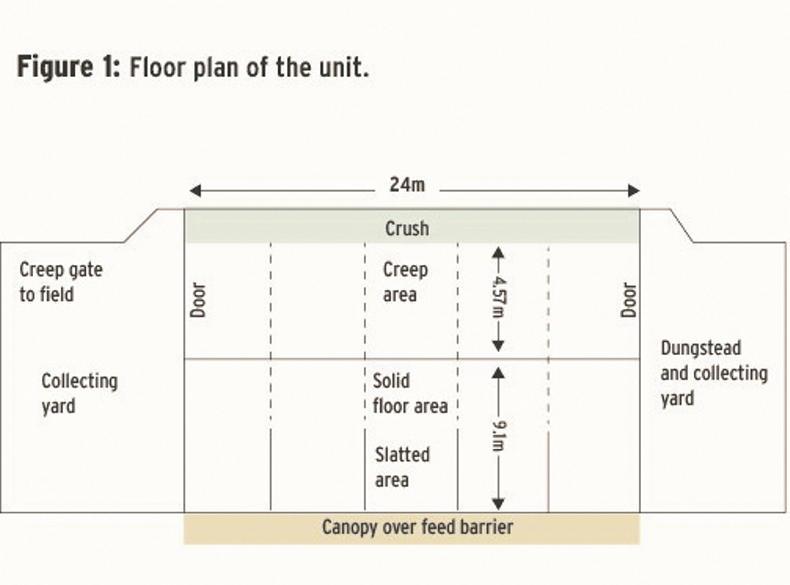

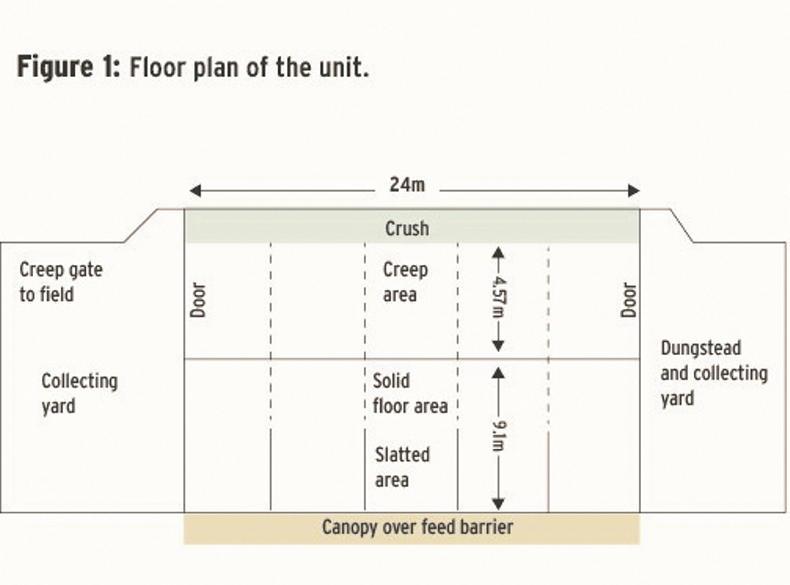

The five-bay shed is an A-frame design, which is open on one side with protection provided against the prevailing wind. The floor plan of the shed is detailed in Figure 1 and this helps to get a clear picture of the design in your mind. A slatted tank runs along the feed passage with agitation points at both ends of the shed. The tank is 4.7m wide and 2.4m deep and provides additional slurry storage for the farm, with capacity for 60 cows for the 16 weeks closed period.

Next to the slatted tank is a solid floored area of similar width and behind this is a solid floored calf creep. There are permanent pen divisions between each of the five slatted tank bays. There are then heavy duty gates which are hung on the stanchions separating the solid floored area and the creep area.

This set-up allows gates to be closed to the permanent divisions on the slatted area, thereby creating five individual pens. However, some or each of the gates can be left open adjacent to the creep penning, allowing pens to be combined or giving licence to cows to move across all five pens. Nicholas says this facility works excellently in encouraging greater heat activity, while it also means only one vasectomised bull is required if used to pick up heats.

The head locking barriers were more expensive to install, but Nicholas says for anyone carrying out AI indoors, or even autumn calving, they quickly reap the rewards of the investment.

Rubber mats

Rubber mats are fixed to the slatted area and the solid-floored section. Research shows the number of mounts received by a cow increases in line with the number of animals in a group, while cows housed on slatted floors (without rubber mats) exhibit the lowest level of activity.

Nicholas finds the combination of letting all cows mix and a solid floor fitted with rubber mats greatly enhances cows in expressing normal breeding behaviour.

The solid floored section is cleaned daily with a simple hand scraper into the slatted tank. This has advantages and disadvantages. It adds a task to the daily routine, but on the plus side it brings benefits during breeding, as it forces someone to monitor heat activity. Nicholas says that if he was just coming to the shed without cleaning, cows would typically be waiting for fresh silage or be less inclined to start mounting other cows. In this situation, cows are accustomed to cleaning and their normal behaviour is unaffected. Once breeding has finished, cows’ heads can be secured in the head locking barriers if desired while scraping the area down.

The creep area can also be divided into sections or combined as one area.

Creep area

The creep area can also be set up similar to the solid floor section with pens divided or gates left open to give all animals access to a certain number of pens or the entire area. Access to cows is provided via a creep gate in each section, with the width of the opening easy to adjust when required. The fact cows’ heads can be caught in the head-locking barriers makes it easy to lock calves away from the cows, which is another aid to enhance resumption to normal oestrus cyclicity.

There are sliding doors at each end of the creep area, allowing for quick cleaning of straw bedding. A dungstead is located at one side of the shed and this also doubles up as a holding pen to direct animals into a crush, which runs along the back of the shed.

Lick holders are fitted on the two end walls of the shed.

Multi-functional

There is a collecting yard/holding pen at the other side of the creep area and this serves a number of functions, with the obvious one to hold animals after passing through the crush. It also serves as a yard where calves can be fed concentrates in troughs and services fields adjoining the yard.

Calves quickly become accustomed to leaving the shed to graze and this is a major benefit in underpinning higher performance. The creep area has heavy duty hay racks hanging along the back wall of the shed, which offers forage to calves if they are locked out from cows.

The yard to the left of the shed doubles up as a collecting/handling area and for feeding calves.

A crush runs the entire length of the back wall of the shed. The fact that there are enclosed pens on both sides of the shed opens up the potential of utilising it as a large handling area. There is an anti-backing gate on the crush, which aids in filling a crush of this length and securing animals if the it is not filled. A well thought-out addition is the fact that the railings are independent to each section and can be easily removed in the case of an animal going down in the crush.

The creep gate allows calves to access grazing in spring and also come back into the year for meal feeding.

The shed was built over 15 years ago as part of the Farm Waste Management Scheme. Nicholas is very happy with the layout and wouldn’t change any aspect of this, with the option to operate sections as open plan an aspect he is most pleased with.

The only change he says he would possibly make if starting out again would be to insert a double tank to eliminate the task of scraping down slats.

“Cows are comfortable on the slats with rubber mats and I do not think having a double tank with rubber mats would have any effect on normal heat expression or animal comfort.”

The labour input required on suckler-beef farms is heavily influenced by the farm’s infrastructure and handling facilities. This statement increases in importance where 100% artificial insemination is practiced. Nicholas Bergin’s family farm in Coolnagh, Roscrea, Co Tipperary, is operated by Nicholas and his wife Bernie, son Danny and daughter Carol.

Nicholas Bergin, Roscrea.

The 100-cow autumn-calving herd, which produces E- and U-grade weanlings, is run on a part-time basis, with Nicholas working with Dovea Genetics as an area representative covering Galway and Offaly. His role is busiest in the first six months of the year and as such, autumn-calving fits best, with calving commencing from the end of July onwards.

The main suckler shed on the farm was built over a decade ago and facilitates the farm’s breeding programme of 100% AI and optimising labour efficiency. Many of the elements included were captured through farm visits during Nicholas’s off-farm work, with much thought invested in planning its design.

The shed

The five-bay shed is an A-frame design, which is open on one side with protection provided against the prevailing wind. The floor plan of the shed is detailed in Figure 1 and this helps to get a clear picture of the design in your mind. A slatted tank runs along the feed passage with agitation points at both ends of the shed. The tank is 4.7m wide and 2.4m deep and provides additional slurry storage for the farm, with capacity for 60 cows for the 16 weeks closed period.

Next to the slatted tank is a solid floored area of similar width and behind this is a solid floored calf creep. There are permanent pen divisions between each of the five slatted tank bays. There are then heavy duty gates which are hung on the stanchions separating the solid floored area and the creep area.

This set-up allows gates to be closed to the permanent divisions on the slatted area, thereby creating five individual pens. However, some or each of the gates can be left open adjacent to the creep penning, allowing pens to be combined or giving licence to cows to move across all five pens. Nicholas says this facility works excellently in encouraging greater heat activity, while it also means only one vasectomised bull is required if used to pick up heats.

The head locking barriers were more expensive to install, but Nicholas says for anyone carrying out AI indoors, or even autumn calving, they quickly reap the rewards of the investment.

Rubber mats

Rubber mats are fixed to the slatted area and the solid-floored section. Research shows the number of mounts received by a cow increases in line with the number of animals in a group, while cows housed on slatted floors (without rubber mats) exhibit the lowest level of activity.

Nicholas finds the combination of letting all cows mix and a solid floor fitted with rubber mats greatly enhances cows in expressing normal breeding behaviour.

The solid floored section is cleaned daily with a simple hand scraper into the slatted tank. This has advantages and disadvantages. It adds a task to the daily routine, but on the plus side it brings benefits during breeding, as it forces someone to monitor heat activity. Nicholas says that if he was just coming to the shed without cleaning, cows would typically be waiting for fresh silage or be less inclined to start mounting other cows. In this situation, cows are accustomed to cleaning and their normal behaviour is unaffected. Once breeding has finished, cows’ heads can be secured in the head locking barriers if desired while scraping the area down.

The creep area can also be divided into sections or combined as one area.

Creep area

The creep area can also be set up similar to the solid floor section with pens divided or gates left open to give all animals access to a certain number of pens or the entire area. Access to cows is provided via a creep gate in each section, with the width of the opening easy to adjust when required. The fact cows’ heads can be caught in the head-locking barriers makes it easy to lock calves away from the cows, which is another aid to enhance resumption to normal oestrus cyclicity.

There are sliding doors at each end of the creep area, allowing for quick cleaning of straw bedding. A dungstead is located at one side of the shed and this also doubles up as a holding pen to direct animals into a crush, which runs along the back of the shed.

Lick holders are fitted on the two end walls of the shed.

Multi-functional

There is a collecting yard/holding pen at the other side of the creep area and this serves a number of functions, with the obvious one to hold animals after passing through the crush. It also serves as a yard where calves can be fed concentrates in troughs and services fields adjoining the yard.

Calves quickly become accustomed to leaving the shed to graze and this is a major benefit in underpinning higher performance. The creep area has heavy duty hay racks hanging along the back wall of the shed, which offers forage to calves if they are locked out from cows.

The yard to the left of the shed doubles up as a collecting/handling area and for feeding calves.

A crush runs the entire length of the back wall of the shed. The fact that there are enclosed pens on both sides of the shed opens up the potential of utilising it as a large handling area. There is an anti-backing gate on the crush, which aids in filling a crush of this length and securing animals if the it is not filled. A well thought-out addition is the fact that the railings are independent to each section and can be easily removed in the case of an animal going down in the crush.

The creep gate allows calves to access grazing in spring and also come back into the year for meal feeding.

The shed was built over 15 years ago as part of the Farm Waste Management Scheme. Nicholas is very happy with the layout and wouldn’t change any aspect of this, with the option to operate sections as open plan an aspect he is most pleased with.

The only change he says he would possibly make if starting out again would be to insert a double tank to eliminate the task of scraping down slats.

“Cows are comfortable on the slats with rubber mats and I do not think having a double tank with rubber mats would have any effect on normal heat expression or animal comfort.”

SHARING OPTIONS