A new suckler shed has recently been built at the Teagasc Grange research farm at Dunsany in Co Meath.

“We had a similar shed on the farm already in the main yard that is working very well so we decided to go with a similar design again for this one,” according to JJ Lenehan, buildings officer with Teagasc based in Grange.

“It is a multifunctional shed.It is designed to hold 150 suckler cows but will also be used for other groups too,” JJ said. “This type of shed would suit someone who is finishing bulls at 16 months old so that they would be out of the shed again before cows would be housed for the winter. “We do a lot of different trials at Grange so the shed has to be able to cater for different groups of stock.”

The shed

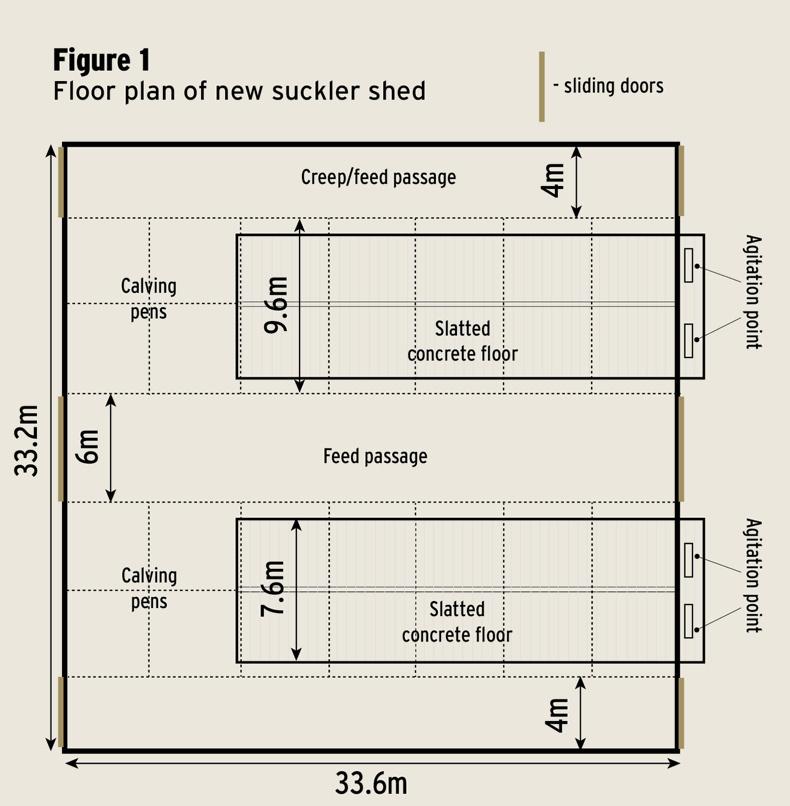

Measuring 33.6m long by 33.2m wide, the shed is practically a square, with both sides having the same internal layout. The shed is seven bays long in total, with a double tank fitted on either side of a central, 6m wide, feed passage. The slatted tanks only account for five of the seven bays, with the remaining two bays dedicated to calving pens.

The double slatted pens have a span of 9.6m. The slatted area accounts for 7.6m of this, with 1m of a solid toenail along either feed barrier, which gives a larger-capacity pen without the expense of having a larger slatted tank. Floor area per cow works out at 3m2 while the tanks provide adequate slurry storage capacity in line with Nitrates Directive requirements. Each double tank has a capacity of 212m2, giving total storage capacity in the shed of 848m2.

The tanks themselves are 25.2m long, 2.4m deep and 7.3m wide, including a 300mm spine wall running in the centre of the tank to provide support for the slats.

Measurements

The shed stands at 4.5m to the eaves, rising to approximately 8.6m at the top of the ridge cap, with a 12° slope on the roof. The walls of the shed are 2.3m high, with approximately 2.2m of vented sheeting in place above this. Vented sheeting is also in place at either end of the shed.

“We went for a big cubic air capacity in this shed with the high 4.5m eaves,” JJ said. “We have a lot of different sheds in Grange and found that it would be the lower sheds with eaves below 3m and smaller cubic air capacity that cattle would struggle in, especially with pneumonia.”

Outside of the shed, gates are being fitted to allow cattle to be moved from one side of the shed to the other at ease, by one man if necessary.

The decision was also made to install spaced sheeting throughout the roof of the shed. While some farmers may be anxious of the amount of moisture that gets in, JJ said: “I wouldn’t go any other way than the spaced sheeting. The amount of moisture that gets in is minimal but there is great capacity for gases and moisture to get out. If there are 150 cows in the shed they are producing a lot of moisture that needs to get out.”

Fibre cement sheeting was installed throughout the roof. This sheeting prevents condensation forming and dripping back down on cattle. It also helps to provide a stable internal temperature, more so than normal sheeting. This could be especially useful where bulls are being finished inside a shed over the summer when temperatures rise.

The shed was not built through the Targeted Agricultural Modernisation Scheme (TAMS) so there was no requirement to leave a continuous opening directly beneath the eaves. As the shed is over 24m wide, the Department specifications outline that a gap of 750mm must be left directly below the eaves. However, the shed is on an exposed site.

An adjoining shed was constructed with the continuous opening running directly below the eaves which had to be boarded up due to the amount of rain entering the shed, and falling on the creep area, even with an overhang in place. This filtered into the decision not to have the opening in this shed and maybe highlights that standard ventilation requirements may not work for all sites.

“We would also be feeding bulls ad-lib on meal in this shed and birds can be a real issue so we had to try and keep it bird proof where possible,” JJ said.

Pens

Between seven and eight cows can fit in each pen, according to JJ. Cows can be fed along the back of the pen at a straight feed bar, while the small gate into the pen has also been designed to provide additional feed space. The neck rails can be adjusted depending what age stock are in the pens.

There is a 15cm step up from the slatted pen to both the creep area and the feed face, which allows cows easier access to reach silage while also preventing slurry from getting out on the creep area.

The creep area will act as a feeding passage for most of the year, but is fitted with gates that can be closed to provide a separate creep pen for each slatted pen. This may be needed if weather conditions are challenging during the spring once cows have calved, as was seen this year.

“The shed is set up so that cows can feed on both sides of the pens,” JJ said. “Then, as cows calve down and stocking rate in the pens reduces, we can convert the feed passages into creep area if needs be, but the hope would be to get cows and calves out to grass as soon as possible after calving.”

Lights

All lights fitted in the shed are LED. However, one uncommon design aspect has seen all lights fitted to the stanchions as opposed to hanging from the roof. Safety was a key consideration when making this decision.

JJ said: “Our role as a research farm allows us to do things like this and see how it works. We have plenty of sheds at Grange where lights are hanging from the roof on chains and they are difficult to replace when they go. We are confident that the design will provide adequate light in the shed.”

Calving facilities

The shed has impressive calving facilities, with eight calving pens, four on either side of the shed, all of which are well equipped. Escape gates mean a farmer can move from one pen to another with ease, providing a quick escape route if dealing with an agitated cow. A small gate with wire mesh is in place at the front of the headgates to prevent calves coming out through them.

Slurry

As the shed is over three bays long, agitation points are required at both ends of the tank. However, with no internal agitation point, another option had to be examined.

The decision was made to install an aeration system throughout the tank which would mean air would be continuously moving through the slurry.

This means the tanks would not have to be mechanically agitated prior to spreading in the spring.

While the pipes have been fitted to the tank, the system itself is not yet installed. The plan for next year will be to recirculate slurry above ground using pipes.

Due to the average suckler farm size, the number of suckler sheds of this scale that are going up in Ireland is limited, but it is important to remember that this shed is first and foremost to be used for research purposes. The total cost of the investment came to €344,000 excluding VAT.

Whatever size of unit is under consideration, buildings constructed to the current Department specifications will have long working lives. This combined with improved labour efficiency and optimising slurry storage and management will ensure a cost-effective investment. There are several interesting design aspects incorporated into the design that farmers could apply to future developments on their own farm, even at a smaller scale.

Oldtown Construction, Portlaoise, Co Laois supplied and erected the shed. They also completed the concrete work for the project. Cembrit supplied the fibre cement sheeting for the roof of the shed. Tegral supplied the metal cladding for the sides of the shed. Condon Engineering supplied and erected all penning.

SHARING OPTIONS