A new six-bay suckler shed is reaching its final stages on the farm of Michael Martyn just outside of Cappataggle, Co Galway. As Michael works full-time off-farm, he needs to ensure that management can be made as streamlined as possible for his suckler herd.

“I was getting stuck for space for cattle and slurry storage so I had to invest,” said Michael. “The existing shed on the farm is a three-bay double but with only four of the pens slatted, with an additional two dry pens, one of which has a small crush. There are no creeps on the shed and it can be difficult to get cattle out of a pen easily.

“Slurry storage is also a big issue in this part of the world. The last few winters have really shown that you need to have enough storage for five or six months of the year if the spring is bad,” Michael said.

The hope is that the new shed will also allow Michael to steadily expand the suckler herd over the coming years.

The shed

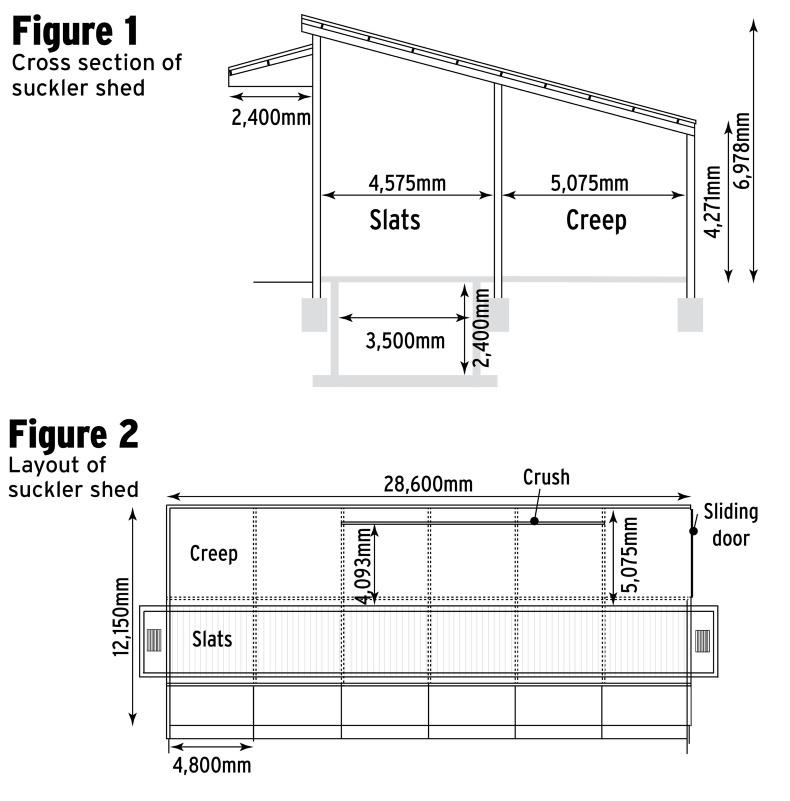

The shed is six, 4.8m wide, bays long measuring a total of 28.6m. It is 12.1m wide and included in this is a 2.4m overhang, a 4.6m slatted area and a 5m-wide creep. The shed stands 4.2m at the eaves, rising to just under 7m at the highest point. A sliding door is in place at one end of the shed to facilitate cleaning of the creep area with a tractor. All steel in the shed has been galvanised to ensure it has a longer life.

“The shed fits in well with the rest of the yard and complements the facilities already in place. Having good handling facilities like these makes managing suckler cows a lot easier and safer,” according to Ciaran Lyons of Lyons Steelwork Ltd, the main contractor for the shed.

Feeding

There is approximately 28.4m of feed space along the front of the shed and if the pens were to be stocked at seven cows per pen it would give feed space per cow of 0.67m. This would allow all cows to line up comfortably beside each other. Adequate space is important to prevent younger or smaller cows being bullied at the feed barrier, this is especially important where feed is restricted.

“We went with 12ft 6in (3.8m) slats. We could have gone with feed barriers along the back but then you would have more cattle in each pen which would lead to a demand for more slurry storage and you would go back to being tight for slurry storage space once again,” Michael outlined.

Internally the current tank measures 31.5m long and 3.5m wide. It is 2.4m (8ft) deep. When measuring the total capacity of the tank you are required to leave 0.2m freeboard along the top, meaning that a depth of 2.2m is used to calculate total capacity. This would give total capacity of the tank of approximately 242m3.

According to the nitrates regulations, suckler cows produce 0.29m3 of slurry per week. As the farm is located in Zone B for nitrates regulations it is required to have 18 weeks of slurry storage capacity. This means that the shed has storage for 46 suckler cows if required for an 18-week housing period. If we wanted capacity for 22 weeks, it would mean that the shed could accommodate 37 cows.

As the shed will be used to house a mixture of youngstock and cows there is ample slurry storage for Michael’s requirements.

Functional

“The new shed is more functional. It has a good big creep which means I can get in with the tractor and clear it out with ease. When you are working full-time off the farm, you have to make life as easy for yourself as possible if you want to make it work,” according to Michael.

As the shed was granted Targeted Agricultural Modernisation Scheme (TAMS) approval before September of 2017 there was no requirement to have individual access to each pen in the creep.

However, for anybody who is thinking of putting up a similar design of a shed the revision to Department of Agriculture specification S123 makes it mandatory to provide separate access to pens within the shed. This means that animals must not have to go through another animal pen to enter or leave the pen.

One option for farmers is to have separate doors at the back of each creep pen, or alternatively, have an access passageway at the rear of the pens. The bottom creep pen in the shed is also fitted with a calving gate.

Fitted along the back wall of the shed is a large crush which measures approximately 14.5m long and 750mm wide.

The large capacity will make handling of larger numbers quicker and safer. An inspection gate is in place just back from the front of the crush which allows somebody to handle an animal while restrained in the head gate. The crush has the added benefit of providing a safe area to observe cattle in the creep area if required.

Ventilation

Vented sheeting is positioned along the entire back wall of the shed to provide inlet ventilation. Another option to increase air movement would have been to leave a continuous opening just below the eaves. However, as the shed is less than 15m wide there is no requirement to do so. Additionally with the shed being open along the front the farmer feels that there should be sufficient airflow.

Outlet ventilation is provided along the apex of the roof, by way of a continuous opening. “I like the open shed, they allow for more air movement which is healthier for cattle,” according to Michael.

Dungstead

A new dungstead has also been constructed adjoining the shed. This will be used to hold farmyard manure from the creep area of the shed. An effluent collection channel runs along the front of the dungstead, directing run-off to the slatted tank of the shed.

The thickness of the concrete slab for the dungstead must not be less than 125mm. It is important for interested farmers to note that dungsteads are not a grant-aided item under TAMS.

“It’s not easy to be farming full-time. I would have been hard pushed to fund this investment without an off-farm income and the good grant support that is available to young farmers,” Michael admitted.

The shed has been put up through TAMS and as Michael qualifies as a young farmer he is eligible for a 60% grant of €80,000. The total cost of the project will exceed €80,000, excluding the cost of the dungstead, so he is hopeful of getting €48,000 in grant aid.

While the application process for TAMS can often be criticised, Michael has had a good experience so far: “I gave plenty of time to make the application and to get approval before starting work on the site. We started work on the shed in March and it was due to be done at the end of August under TAMS. However, we knew we wouldn’t have it done on time so we made contact with the Department and got a month’s extension.”

Lyons Steelwork Ltd were responsible for carrying out all work on the shed. “It makes life easier when you have one person looking after everything especially when you are working full time it’s not always easy to organise everything yourself,” Michael said.

The penning was supplied by Teemore Engineering but was fitted by Lyons Steelwork Ltd. Banagher Precast Concrete supplied the slats for the tank. The plans for the shed were done by O’Brien Survey and Design Services, Mountbellew while the TAMS application was submitted by Teagasc Ballinasloe.

SHARING OPTIONS