A few months ago, Lemken announced it was to begin marketing a weather station for use on farms. In doing this, the machinery company entered into a partnership with Dutch software development company AppsforAgri to help develop and deliver products for farm use.

The collaboration between the two companies targets the development of a range of sensor technologies through associated apps on smartphones. The challenge is to develop integrated solutions that can hopefully marry machines, fields, sensors and network apps. The Lemken weather station is the first product from this collaboration.

While one can now purchase a semi-automated weather station for as little as €100, more professional units used for disease or pest monitoring decision-support systems tend to be around 30 times that cost.

Affordable decision support

This unit was developed to act as a decision support system. I recently met with a friend from the Netherlands, Erno Bouma, who has considerable knowledge of plants, weather and software development.

He told me that he was one of the people behind the development of the software for the Lemken weather station and the conversation continued.

Firstly, this sophisticated weather station is more affordable. It is being made available at an initial deposit cost of approximately €770 per unit over the three years, plus a €30 per month license for the plant protection module for the three years. So there is relatively little capital outlay required and after that the farmer owns the unit.

The weather station monitors a number of important variables for the determination of pathogen development and also for crop growth. It is a columnar construction set at least 40cm deep into the ground. It measures soil temperature at 20cm and 5cm depth. It also has two surface wetness measurement devices, one set in the crop’s canopy and the other above it.

The basic unit does not measure rainfall, but rather interacts with meteorological radar to get rainfall levels. However, a rainfall meter can be fitted where the met data is not accessible or where radar coverage is regarded as incomplete.

The weather station interacts with many different devices to complete information gathering and transfer. Information is then sent to the farmer’s smart phone where the details can be read within an app.

The weather station collects information on soil and air temperature, rainfall and leaf wetness and sends it for computation to give advice and recommendations to the farmer for each specific monitored crop.

Modern technology used on this device transmits the data via a low frequency network called SigFox. This is used to both collect initial data, send it for computation and then send it to SmartFarming app on the farmer’s smartphone or tablet. This signal system was chosen because of its low power requirement.

Despite transmitting data every 30 minutes, the total energy requirement gives a standard domestic battery a working life of up to five years.

Technical interaction

Erno is the author of a book called Weather and Plant Protection and he has a huge knowledge of the many factors that influence both pest development and the interaction between the plant and plant protection products. This knowledge is used within this weather station and the Spray Weather Guide app gives specific spray timing advice for all approved products. This information is then delivered through the phone app to the farmer.

As crop practitioners, we are very aware of the variable performance of some crop protection products. We sometimes put this down to weather before, during or after application, but does this really make such a big difference? Erno says it does.

The software is programmed to advise on the suitability of hourly slots for the application of specific products. This takes into account the characteristics of the actives, its formulation, etc. This information is then used to take advantage of the weather conditions that will apply in the crop to help achieve optimum application timing and performance. This information should then help deliver optimum performance efficacy more often.

Spraying conditions and

product efficacy

When it is time for a specific job, the details of product choice, etc, can be entered into the app. The information is then processed to produce specific timing recommendation graphs for the grower and shown on the app.

Figure 1. Spraying conditions and the hourly suitability of conditions for the application of Battle Delta (Firebird) on winter wheat.Figure 1.

Examples can show a very quick fall-off in optimum application conditions for individual products. Might this explain variable field to field performance of the same treatment in adjacent fields?

An example of this can be seen in Figure 1 for a winter wheat herbicide called Battle Delta. This is a screenshot of the information provided on the online Spray Weather Guide when a specific crop and product are chosen on the app software. The underlying weather data used is Irish data from 3-4 May 2017.

The lower of the two graphs in Figure 1 gives the conditions that will apply for spraying in hourly slots from midnight on 3 May to 5 May. When the hour slot is a green bar, spraying conditions are thought to be suitable, while conditions are deemed not suitable for spraying when the bars are red. The height of the bar is proportionate to its value.

The upper of the two graphs in Figure 1 is a calculated representation of the suitability of weather conditions for the application of commercial products. In this case, Battle Delta is effectively Firebird. Ignore the fact that one would not be applying Firebird at that time of year and that it is past its latest application timing date – this is just an example of the implication of product choice on the suitability or otherwise of application conditions.

It is interesting to note that on 3 May, the singularly most suitable slot to apply this product was between 22.00 and 23.00hrs, despite the fact that better spraying conditions occurred earlier. A wider application window was available from 16.00 to 24.00hrs on 4 May.

Figure 2. Spraying conditions and the hourly suitability of conditions for the application of Traton SX (BiPlay SX) on winter wheat.Figure 2.

Assuming similar spraying conditions on the same day and date, the window of optimum suitability for application of Traton SX (BiPlay SX) was broadly similar, but this falls away dramatically to give no or poor effect either side of this on 3 May, as shown in Figure 2. This would be bad news for weed control.

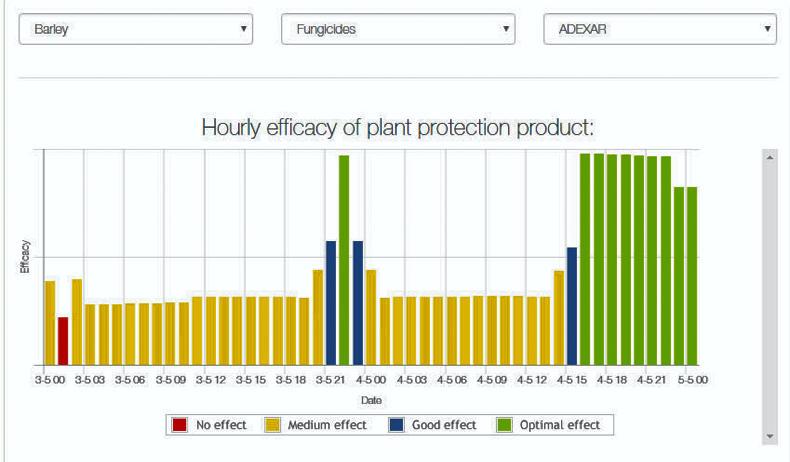

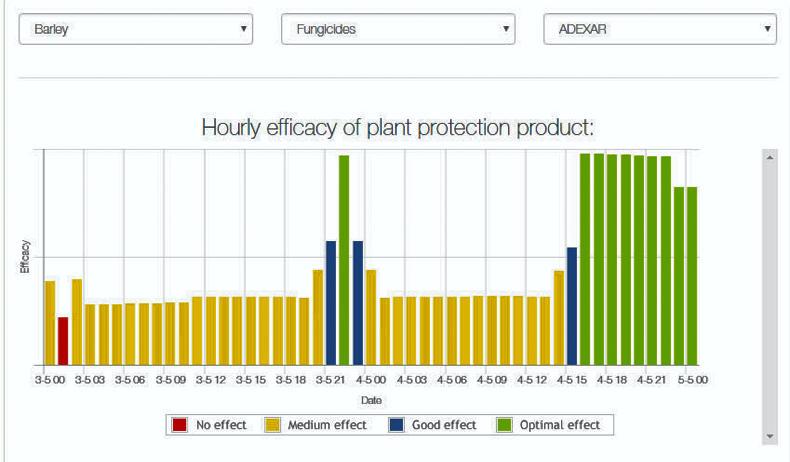

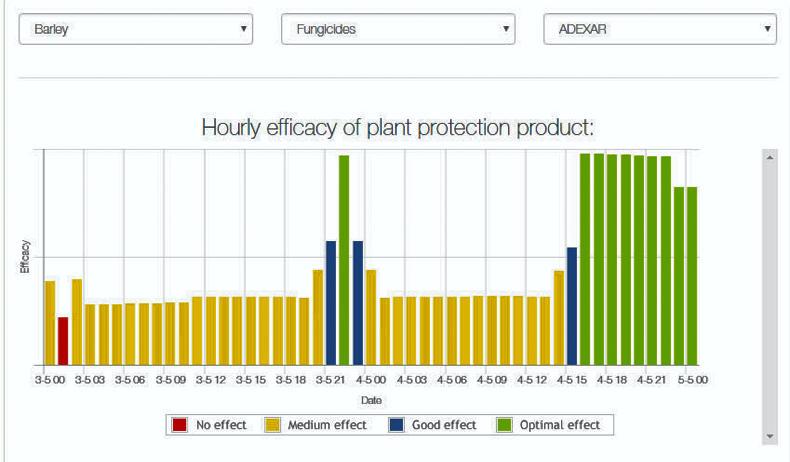

Figure 3. Spraying conditions and the hourly suitability for the application of Adexar on winter barley on 3 May.Figure 3. Spraying conditions and the hourly suitability for the application of Adexar on winter barley on 3 May.

If on the same day Adexar was being considered for disease control, the window of application for barley would be broadly similar for 3 May (Figure 3), but it falls away to a medium effect before and after the optimum timing of 10pm. As with the other products, there is a wider optimum window on the evening of the following day.

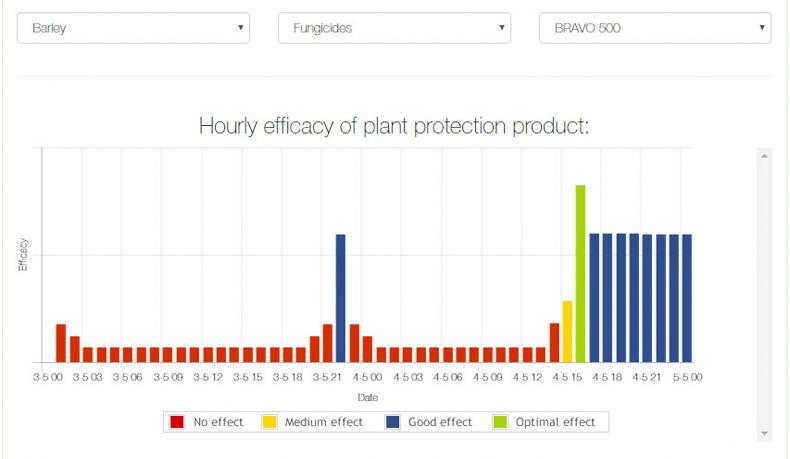

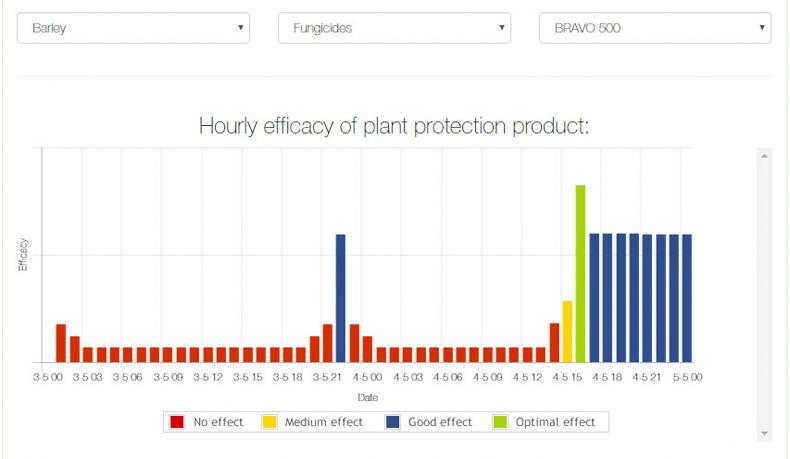

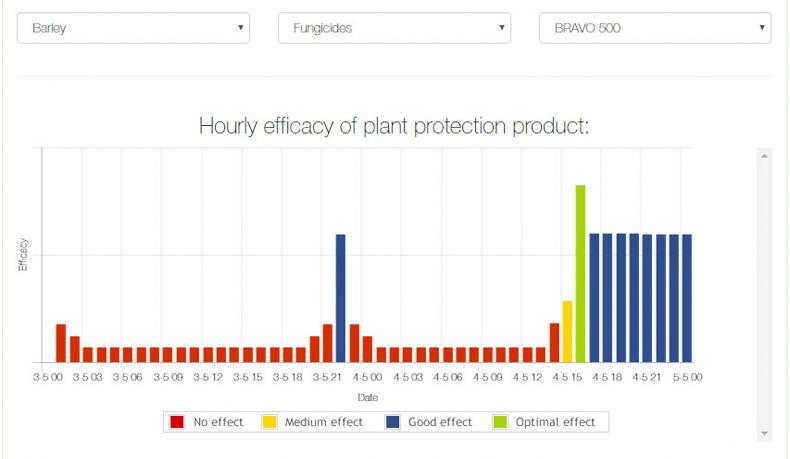

Figure 4. Spraying conditions and the hourly suitability for the application of Bravo 500 on winter barley on 3 May.Figure 4. Spraying conditions and the hourly suitability for the application of Bravo 500 on winter barley on 3 May.

Interestingly, while all three previous product examples had optimum conditions on 3 May between 10 and 11pm, and again the following evening, if Bravo was to be applied on the barley with the Adexar, it only had optimum conditions in this time slot between 16.00 and 17.00hrs on 4 May, despite the presence of good spraying conditions (Figure 4).

It must also be noted from Figure 4 that the efficacy level falls quite low during most other periods on 3 May and this was the only product not to have optimum application efficacy in the evening of 4 May.

While many of the products in these examples had broadly similar periods of optimum efficacy, some, such as BiPlay, were expected to show poor efficacy during most of 3 May and in the earlier part of 4 May. Bravo is shown to suffer worst in this regard.

These examples show that optimum efficacy conditions vary between products and that this could be an issue for some growers when forced to use less favourable conditions during difficult periods for spraying.

These recommendations can change dramatically as the weather changes and the advice is representative of the conditions that apply on individual days. So it seems that this decision support tool could bring considerable benefit, but they still depend on having spraying windows that could be regarded as optimum. Unfortunately, we cannot guarantee this in Ireland, but it will still be interesting to watch how these technologies develop into the future.

For more information one can contact Lemken (www.lemken.com) or Apps for Agri (www.smartfarm.nl/en/).

The new weather station from Lemken is more than just a weather station.The Spray Weather Guide App will be launched this spring and provides information on the availability of optimum conditions for spraying. Background information also provides advice on when the optimum efficacy of individual plant protection products can be achieved.

A few months ago, Lemken announced it was to begin marketing a weather station for use on farms. In doing this, the machinery company entered into a partnership with Dutch software development company AppsforAgri to help develop and deliver products for farm use.

The collaboration between the two companies targets the development of a range of sensor technologies through associated apps on smartphones. The challenge is to develop integrated solutions that can hopefully marry machines, fields, sensors and network apps. The Lemken weather station is the first product from this collaboration.

While one can now purchase a semi-automated weather station for as little as €100, more professional units used for disease or pest monitoring decision-support systems tend to be around 30 times that cost.

Affordable decision support

This unit was developed to act as a decision support system. I recently met with a friend from the Netherlands, Erno Bouma, who has considerable knowledge of plants, weather and software development.

He told me that he was one of the people behind the development of the software for the Lemken weather station and the conversation continued.

Firstly, this sophisticated weather station is more affordable. It is being made available at an initial deposit cost of approximately €770 per unit over the three years, plus a €30 per month license for the plant protection module for the three years. So there is relatively little capital outlay required and after that the farmer owns the unit.

The weather station monitors a number of important variables for the determination of pathogen development and also for crop growth. It is a columnar construction set at least 40cm deep into the ground. It measures soil temperature at 20cm and 5cm depth. It also has two surface wetness measurement devices, one set in the crop’s canopy and the other above it.

The basic unit does not measure rainfall, but rather interacts with meteorological radar to get rainfall levels. However, a rainfall meter can be fitted where the met data is not accessible or where radar coverage is regarded as incomplete.

The weather station interacts with many different devices to complete information gathering and transfer. Information is then sent to the farmer’s smart phone where the details can be read within an app.

The weather station collects information on soil and air temperature, rainfall and leaf wetness and sends it for computation to give advice and recommendations to the farmer for each specific monitored crop.

Modern technology used on this device transmits the data via a low frequency network called SigFox. This is used to both collect initial data, send it for computation and then send it to SmartFarming app on the farmer’s smartphone or tablet. This signal system was chosen because of its low power requirement.

Despite transmitting data every 30 minutes, the total energy requirement gives a standard domestic battery a working life of up to five years.

Technical interaction

Erno is the author of a book called Weather and Plant Protection and he has a huge knowledge of the many factors that influence both pest development and the interaction between the plant and plant protection products. This knowledge is used within this weather station and the Spray Weather Guide app gives specific spray timing advice for all approved products. This information is then delivered through the phone app to the farmer.

As crop practitioners, we are very aware of the variable performance of some crop protection products. We sometimes put this down to weather before, during or after application, but does this really make such a big difference? Erno says it does.

The software is programmed to advise on the suitability of hourly slots for the application of specific products. This takes into account the characteristics of the actives, its formulation, etc. This information is then used to take advantage of the weather conditions that will apply in the crop to help achieve optimum application timing and performance. This information should then help deliver optimum performance efficacy more often.

Spraying conditions and

product efficacy

When it is time for a specific job, the details of product choice, etc, can be entered into the app. The information is then processed to produce specific timing recommendation graphs for the grower and shown on the app.

Figure 1. Spraying conditions and the hourly suitability of conditions for the application of Battle Delta (Firebird) on winter wheat.Figure 1.

Examples can show a very quick fall-off in optimum application conditions for individual products. Might this explain variable field to field performance of the same treatment in adjacent fields?

An example of this can be seen in Figure 1 for a winter wheat herbicide called Battle Delta. This is a screenshot of the information provided on the online Spray Weather Guide when a specific crop and product are chosen on the app software. The underlying weather data used is Irish data from 3-4 May 2017.

The lower of the two graphs in Figure 1 gives the conditions that will apply for spraying in hourly slots from midnight on 3 May to 5 May. When the hour slot is a green bar, spraying conditions are thought to be suitable, while conditions are deemed not suitable for spraying when the bars are red. The height of the bar is proportionate to its value.

The upper of the two graphs in Figure 1 is a calculated representation of the suitability of weather conditions for the application of commercial products. In this case, Battle Delta is effectively Firebird. Ignore the fact that one would not be applying Firebird at that time of year and that it is past its latest application timing date – this is just an example of the implication of product choice on the suitability or otherwise of application conditions.

It is interesting to note that on 3 May, the singularly most suitable slot to apply this product was between 22.00 and 23.00hrs, despite the fact that better spraying conditions occurred earlier. A wider application window was available from 16.00 to 24.00hrs on 4 May.

Figure 2. Spraying conditions and the hourly suitability of conditions for the application of Traton SX (BiPlay SX) on winter wheat.Figure 2.

Assuming similar spraying conditions on the same day and date, the window of optimum suitability for application of Traton SX (BiPlay SX) was broadly similar, but this falls away dramatically to give no or poor effect either side of this on 3 May, as shown in Figure 2. This would be bad news for weed control.

Figure 3. Spraying conditions and the hourly suitability for the application of Adexar on winter barley on 3 May.Figure 3. Spraying conditions and the hourly suitability for the application of Adexar on winter barley on 3 May.

If on the same day Adexar was being considered for disease control, the window of application for barley would be broadly similar for 3 May (Figure 3), but it falls away to a medium effect before and after the optimum timing of 10pm. As with the other products, there is a wider optimum window on the evening of the following day.

Figure 4. Spraying conditions and the hourly suitability for the application of Bravo 500 on winter barley on 3 May.Figure 4. Spraying conditions and the hourly suitability for the application of Bravo 500 on winter barley on 3 May.

Interestingly, while all three previous product examples had optimum conditions on 3 May between 10 and 11pm, and again the following evening, if Bravo was to be applied on the barley with the Adexar, it only had optimum conditions in this time slot between 16.00 and 17.00hrs on 4 May, despite the presence of good spraying conditions (Figure 4).

It must also be noted from Figure 4 that the efficacy level falls quite low during most other periods on 3 May and this was the only product not to have optimum application efficacy in the evening of 4 May.

While many of the products in these examples had broadly similar periods of optimum efficacy, some, such as BiPlay, were expected to show poor efficacy during most of 3 May and in the earlier part of 4 May. Bravo is shown to suffer worst in this regard.

These examples show that optimum efficacy conditions vary between products and that this could be an issue for some growers when forced to use less favourable conditions during difficult periods for spraying.

These recommendations can change dramatically as the weather changes and the advice is representative of the conditions that apply on individual days. So it seems that this decision support tool could bring considerable benefit, but they still depend on having spraying windows that could be regarded as optimum. Unfortunately, we cannot guarantee this in Ireland, but it will still be interesting to watch how these technologies develop into the future.

For more information one can contact Lemken (www.lemken.com) or Apps for Agri (www.smartfarm.nl/en/).

The new weather station from Lemken is more than just a weather station.The Spray Weather Guide App will be launched this spring and provides information on the availability of optimum conditions for spraying. Background information also provides advice on when the optimum efficacy of individual plant protection products can be achieved.

SHARING OPTIONS