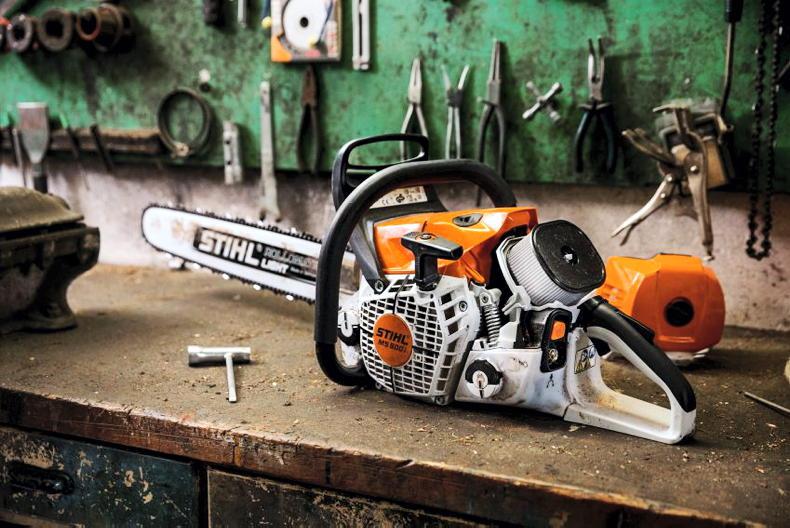

With the majority of cattle now housed, some farmers may go to the workshop and pull out the trusty chainsaw to tackle some lingering tasks. Used as a seasonal tool on many farms, we often expect the chainsaw to perform at the pull of the cord. However, there are a number of components that rely on each other to get the best out of the saw. Here are some pointers on how to get your chainsaw ready for the chop this winter.

It's good practice with chainsaw maintenance to replace the spark plug at every service. A spark plug will only cost in the region of €5.

Starting off

If the chainsaw fails when starting up, there’s a good chance that the spark plug may be defective. Remove the spark plug and inspect it. If the porcelain insulator is cracked, an electrode may be burned or damaged, or there could be a heavy carbon build-up, so it needs to be replaced. A spark plug will only cost in the region of €5. When replacing, operators should take note of its condition. A grey colouring on the spark plug may indicate damage to the piston. This discolouration could be a result of aluminium burning in the cylinder.

When starting from cold, use the air purge device, if fitted. This will fill the fuel line and carburettor with fuel and push the air out, allowing it to start much quicker. From here, switch on and pull on the choke. Pull the start cord until the engine fires and disengauge the choke. If you miss the kick and proceed to pull one or two more times with the choke out, you will flood the saw. After the kick, let off the choke and pull and it should start.

The fuel filter should be replaced at every service. A typical fuel filter will cost €5 to €6.

Engine flooding occurs when petrol gets in the compression chamber before it ignites.

This stagnant petrol prevents the spark and ignition of the engine. As a result, it must be drained from the system beforehand. The best way to do this is through persistent, repeated attempts yanking the pull cord with the saw switched off. Once you get it to start, run the saw until it clears itself of the heavy exhaust fumes from the flooded engine.

Oil

It’s vital that chainsaw operators use good quality chainsaw chain oil and NOT waste oil found lying around a workshop. There is a reason this oil has been removed from an engine, as it has a high sulphur content and reduced lubrication qualities.

Like any chain oil, whether it be used for a chain on a baler or a forage wagon, it needs to have proper cling qualities so it is not flung off the chain at the time of application. The viscosity of the oil needs to be suitable for a chainsaw. If the oil is too thin, the saw will use too much oil, while on the other hand if the oil is too thick, it will not lubricate the chain properly. It also needs to be able to withstand high temperatures. Proper chainsaw oil is readily available in most hardware stores.

It’s good practice to fill the chain oil tank every time the operator fills the chainsaw with two-stroke. Ensure you use a good-quality, recognised brand of two-stroke oil and mix it with the petrol at the proper ratio.

It’s vital that chainsaw operators use good quality chainsaw chain oil and NOT waste oil found lying around a workshop.

Air and fuel filter

If a chainsaw has been left unused for a number of months, some of the ingredients in the two-stroke fuel mix may evaporate, leaving behind a thick jelly-like substance. This may cause a clogged carburetor. If the carburetor is clogged, try cleaning it with carburetor cleaner. If this isn’t effective, rebuild or replace the carburettor. For a saw that hasn’t been used for a number of months, it is a good idea to empty the fuel tank and re-fill it with fresh fuel. The fuel filter should be replaced at every service and typically costs €5 to €6.

It’s very important to keep the air filter free of debris. If it becomes clogged, the engine may get too much fuel and not enough air, causing the engine to stall or run rough. The air filter should be removed and cleaned or replaced on a regular basis. The vents should also be cleaned out to ensure the air intake is not blocked, otherwise the saw may overheat.

The easiest way to maintain the chain is to get it professionally sharpened, which will cost around €8 to €10, depending on the size of chain.

Chain

The amount of work you are doing with the saw will determine how often the chain will need to be sharpened. The golden rule is that if you find yourself leaning on the saw to make it cut, then you need to sharpen the chain.

There are a few options when it comes to sharpening the chain. The easiest way is to get it professionally sharpened, which will cost around €8 to €10, depending on the size of chain.

There are numerous tools on the market to aid the sharpening process. One such tool is a two-in-one file holder. This will sharpen the cutting tooth and wear the depth gauge at the same time.

Each cutting tooth has a mark on the top of it called a witness mark, which serves two functions. Firstly, it indicates the sharpening angle and secondly, it marks the end of the life of the chain when filed to this point.

It’s vital that operators are aware that as a chain is sharpened, the depth gauge needs to be lowered. If the depth gauge is too low, the saw will be hopping or jumping off the timber, resulting in a dangerous scenario where it may be difficult to hold the saw. If the depth gauge is too high, the chainsaw will be unable to cut the timber. It will eventually damage the bottom of the guide and the chain.

After sharpening the chain, it’s important to correctly set the chain adjuster. The chain should be placed on the guide bar and tightened until it’s resting against the bottom of the guide bar. The saw should then be run for one to two minutes. The chain may need to be retightened, if necessary.

Chain brake, guide bar and sprocket

It’s absolutely essential that the chain brake safety feature is functional. This is a steel band around the clutch drum, which is activated in an emergency situation, stopping the chain with immediate effect. If a chainsaw has no chain brake, it most definitely should not be used.

The chain guide bar also needs to be maintained. The chain track should be kept clean to allow the chain oil to lubricate the chain properly.

The chain track needs to be clean, to allow the chain oil to lubricate the chain properly.

There is a sprocket at one end of the chain guide bar, on which the chain rotates. There is a bearing inside this sprocket which needs to be greased regularly, to allow it to rotate freely.

The guide bar itself will occasionally have to be replaced. If the guide bar channels have widened to the stage where the chain has become loose, then it will definetly need replacing.

With the majority of cattle now housed, some farmers may go to the workshop and pull out the trusty chainsaw to tackle some lingering tasks. Used as a seasonal tool on many farms, we often expect the chainsaw to perform at the pull of the cord. However, there are a number of components that rely on each other to get the best out of the saw. Here are some pointers on how to get your chainsaw ready for the chop this winter.

It's good practice with chainsaw maintenance to replace the spark plug at every service. A spark plug will only cost in the region of €5.

Starting off

If the chainsaw fails when starting up, there’s a good chance that the spark plug may be defective. Remove the spark plug and inspect it. If the porcelain insulator is cracked, an electrode may be burned or damaged, or there could be a heavy carbon build-up, so it needs to be replaced. A spark plug will only cost in the region of €5. When replacing, operators should take note of its condition. A grey colouring on the spark plug may indicate damage to the piston. This discolouration could be a result of aluminium burning in the cylinder.

When starting from cold, use the air purge device, if fitted. This will fill the fuel line and carburettor with fuel and push the air out, allowing it to start much quicker. From here, switch on and pull on the choke. Pull the start cord until the engine fires and disengauge the choke. If you miss the kick and proceed to pull one or two more times with the choke out, you will flood the saw. After the kick, let off the choke and pull and it should start.

The fuel filter should be replaced at every service. A typical fuel filter will cost €5 to €6.

Engine flooding occurs when petrol gets in the compression chamber before it ignites.

This stagnant petrol prevents the spark and ignition of the engine. As a result, it must be drained from the system beforehand. The best way to do this is through persistent, repeated attempts yanking the pull cord with the saw switched off. Once you get it to start, run the saw until it clears itself of the heavy exhaust fumes from the flooded engine.

Oil

It’s vital that chainsaw operators use good quality chainsaw chain oil and NOT waste oil found lying around a workshop. There is a reason this oil has been removed from an engine, as it has a high sulphur content and reduced lubrication qualities.

Like any chain oil, whether it be used for a chain on a baler or a forage wagon, it needs to have proper cling qualities so it is not flung off the chain at the time of application. The viscosity of the oil needs to be suitable for a chainsaw. If the oil is too thin, the saw will use too much oil, while on the other hand if the oil is too thick, it will not lubricate the chain properly. It also needs to be able to withstand high temperatures. Proper chainsaw oil is readily available in most hardware stores.

It’s good practice to fill the chain oil tank every time the operator fills the chainsaw with two-stroke. Ensure you use a good-quality, recognised brand of two-stroke oil and mix it with the petrol at the proper ratio.

It’s vital that chainsaw operators use good quality chainsaw chain oil and NOT waste oil found lying around a workshop.

Air and fuel filter

If a chainsaw has been left unused for a number of months, some of the ingredients in the two-stroke fuel mix may evaporate, leaving behind a thick jelly-like substance. This may cause a clogged carburetor. If the carburetor is clogged, try cleaning it with carburetor cleaner. If this isn’t effective, rebuild or replace the carburettor. For a saw that hasn’t been used for a number of months, it is a good idea to empty the fuel tank and re-fill it with fresh fuel. The fuel filter should be replaced at every service and typically costs €5 to €6.

It’s very important to keep the air filter free of debris. If it becomes clogged, the engine may get too much fuel and not enough air, causing the engine to stall or run rough. The air filter should be removed and cleaned or replaced on a regular basis. The vents should also be cleaned out to ensure the air intake is not blocked, otherwise the saw may overheat.

The easiest way to maintain the chain is to get it professionally sharpened, which will cost around €8 to €10, depending on the size of chain.

Chain

The amount of work you are doing with the saw will determine how often the chain will need to be sharpened. The golden rule is that if you find yourself leaning on the saw to make it cut, then you need to sharpen the chain.

There are a few options when it comes to sharpening the chain. The easiest way is to get it professionally sharpened, which will cost around €8 to €10, depending on the size of chain.

There are numerous tools on the market to aid the sharpening process. One such tool is a two-in-one file holder. This will sharpen the cutting tooth and wear the depth gauge at the same time.

Each cutting tooth has a mark on the top of it called a witness mark, which serves two functions. Firstly, it indicates the sharpening angle and secondly, it marks the end of the life of the chain when filed to this point.

It’s vital that operators are aware that as a chain is sharpened, the depth gauge needs to be lowered. If the depth gauge is too low, the saw will be hopping or jumping off the timber, resulting in a dangerous scenario where it may be difficult to hold the saw. If the depth gauge is too high, the chainsaw will be unable to cut the timber. It will eventually damage the bottom of the guide and the chain.

After sharpening the chain, it’s important to correctly set the chain adjuster. The chain should be placed on the guide bar and tightened until it’s resting against the bottom of the guide bar. The saw should then be run for one to two minutes. The chain may need to be retightened, if necessary.

Chain brake, guide bar and sprocket

It’s absolutely essential that the chain brake safety feature is functional. This is a steel band around the clutch drum, which is activated in an emergency situation, stopping the chain with immediate effect. If a chainsaw has no chain brake, it most definitely should not be used.

The chain guide bar also needs to be maintained. The chain track should be kept clean to allow the chain oil to lubricate the chain properly.

The chain track needs to be clean, to allow the chain oil to lubricate the chain properly.

There is a sprocket at one end of the chain guide bar, on which the chain rotates. There is a bearing inside this sprocket which needs to be greased regularly, to allow it to rotate freely.

The guide bar itself will occasionally have to be replaced. If the guide bar channels have widened to the stage where the chain has become loose, then it will definetly need replacing.

SHARING OPTIONS