As the country continues to reopen and gradually transition back to some form of normality, manufacturers and dealers have once again started to organise demonstration events.

Last week, well-known John Deere tractor dealership Farm Power Ltd and Lemken teamed up on a three-day working demonstration tour, which took place at three different locations across Co Cork.

Attendees were given the chance to see the German manufacturer’s latest cultivation and sowing equipment, with machines to suit both conventional and minimum tillage systems in action.

Here, we take a look at some of the highlights.

Karat cultivator.

Although one of the simpler machines in action at the event, Lemken area sales manager for Ireland Derek Delahunty described the Karat cultivator as the star of the show.

With stubble cultivation changing in recent years, this machine can be used to control weeds, loosen soils and/or incorporate chopped straw. It has seen a recent surge in popularity largely down to the Tillage Capital Investment Scheme.

The Karat 9 is available in working widths from 3m to 7m. The tines are arranged on the cultivator frame with an average line distance of 28cm for mixing of soil and straw. The Karat legs feature a quick change system. The interchangeable share foot can be removed using a linchpin, without the need for tools.

Karat cultivator.

Lemken offers its cultivator shares in eight different configurations for working depths between 5cm and 30cm. The standard shares are hard-faced, while carbide-coated are available as an optional extra. Angular concave discs sit behind the tines to further mix the soil and straw while helping to level the ground.

Lemken offer its cultivator shares in eight different configurations for working depths between 5cm and 30cm.

A trailing roller is used for soil reconsolidation. Depending on the spec, the working depth is either adjusted manually or via the trailing roller. Prices for the Karat 9 U start from €15,000 plus VAT.

Compact Solitair 9.

Much of Lemken’s range is modular, making it possible to mix and match different seeding combinations with a disc or power harrow configuration.

For those after a high-capacity high-output seed drill, Lemken showcased its Compact Solitair 9.

Although none of these machines has been sold in Ireland for 10 years, Derek noted that the market is changing and going around in a circle, with renewed interest in such a configuration.

Solitair 25.

This drill features hydraulically-adjustable levelling tines, which are followed by individually sprung concave discs.

Staggered wheels with a diameter of 1,064mm (420/65 R20) help to reconsolidate the seed bed. The machine pictured featured a trapeze packer roller for further pre-consolidation of rows directly in front of the double disc coulters.

Lemken says that as the tyre packer roller in front of the trapeze packer roller features large tyres, it has a minimal effect on draft requirement.

Each double-disc coulter has 125cm spacings and is individually guided by a rubber-tyred depth wheel and features up to 70kg of pressure. The 3m drill features two distribution heads with section control.

With a 3,500l tank capacity, time spent loading is significantly reduced compared with the firm’s typical one-pass system, which features a 1,800l hopper.

With an average forward speed in the region of 12km/h to 15km/h achievable on an 180hp tractor, Derek noted that the unit is capable of achieving 30% more output than a power harrow configuration drill. Prices start at €54,000 plus VAT.

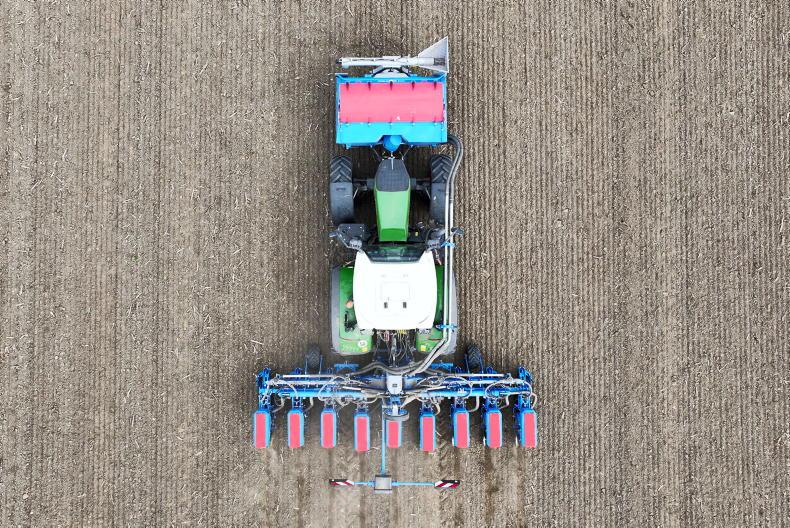

Solitair 25.

Another example of Lemken’s modular design is the Solitair 25. This unit is essentially a trailed power harrow with a seed hopper mounted on the chassis and a seeding unit attached via the three-point linkage at the rear.

The option is also there to configure this setup with an eight-row maize seeding unit, with one such setup sold in Co Armagh last year.

The unit is available in working widths from 4m to 6m. The combination on display saw a Zirkon 12-power harrow with a mounted trapeze packer followed by the double-disc seed coulters.

When sowing, the transport wheels tend to ride slightly off the ground.

Solitair 25.

The metering and distribution system on the drill dispenses the seed to four distributor heads via four vertically arranged metering units. Each metering unit is driven by a separate electrical motor. It allows seed rates of 0.5kg/ha to 500kg/ha.

Part width section control is available as standard. The plastic hopper features a 3,000l capacity, while the unit comes with the option of a hydraulically powered filling auger. The 4m complete configuration is priced from €80,000 plus VAT.

Juwel 7 plough.

Precise plough settings are crucial to minimising wear and to reduce fuel consumption.

Lemken claims its Optiquick setting system helps to minimise both. Optiquick can be used to set the front furrow width independently from the tractor/plough pull line. This system is designed to avoid any side forces. By adjusting the turnbuckle, the system works towards pulling the plough through the tractor’s back axle in a straight line.

Lemken’s range of Juwel ploughs are available with 90cm, 100cm or 120cm body spacing. Its basic version allows four different working widths to be set, while the Juwel M V features hydraulic working width adjustment as standard. Using a double-acting hydraulic cylinder, working widths from 30cm to 60cm per body can be set from the tractor seat.

Both the Juwel and the Juwel M V feature a shear pin in the standard specification. The Juwel 7/8 M T and Juwel 7/8 M VT versions feature the hydromatic auto-reset trip device, which enables the plough bodies to move simultaneously upwards and to the side.

Although a solid headboard is available, Derek outlined that 90% of Lemken ploughs in Ireland use slatted headboards, while all feature hydraulically operated depth control.

The Jewel 7 four-furrow starts at €19,900 plus VAT.

Steketee mechanical hoe.

In recent years, we have seen some of the larger European tillage equipment manufacturers either develop their own mechanical weeding equipment or purchase such specialised manufacturing companies.

Three years ago, Lemken purchased Steketee, a Dutch manufacturer of mechanical weeding options. This purchase followed Lemken putting a halt to the production of sprayers.

Although the unit arrived in Ireland earlier this year, last week’s event marked the first Irish public appearance of the inter-row weeder. This particular hoe was configured to work on 1m-wide four double-row carrot beds.

Steketee mechanical hoe.

Each machine can be configured to the specific planter and crop sown, with adjustments easily made on the sliding rails. Various weeding shares, discs, blades, tines or elements can be configured accordingly. The weeder comes with automatic or manual steering systems.

This particular hoe is reliant on camera technology that uses plant imaging. The system works by identifying the desired plant and removing everything else around it, which includes weeds of the wrong shape or colour.

Manual steering can also be used and involves an operator sitting on the seat in the rear of the weeder, manually controlling the machines steering using a joystick.

Row widths from 15cm to 100cm are possible, while working widths of up to 13m are available. Lemken is intending to run a series of farm visits and seminars on the topic over the coming months.

Prices start at €8,000 plus VAT.

As the country continues to reopen and gradually transition back to some form of normality, manufacturers and dealers have once again started to organise demonstration events.

Last week, well-known John Deere tractor dealership Farm Power Ltd and Lemken teamed up on a three-day working demonstration tour, which took place at three different locations across Co Cork.

Attendees were given the chance to see the German manufacturer’s latest cultivation and sowing equipment, with machines to suit both conventional and minimum tillage systems in action.

Here, we take a look at some of the highlights.

Karat cultivator.

Although one of the simpler machines in action at the event, Lemken area sales manager for Ireland Derek Delahunty described the Karat cultivator as the star of the show.

With stubble cultivation changing in recent years, this machine can be used to control weeds, loosen soils and/or incorporate chopped straw. It has seen a recent surge in popularity largely down to the Tillage Capital Investment Scheme.

The Karat 9 is available in working widths from 3m to 7m. The tines are arranged on the cultivator frame with an average line distance of 28cm for mixing of soil and straw. The Karat legs feature a quick change system. The interchangeable share foot can be removed using a linchpin, without the need for tools.

Karat cultivator.

Lemken offers its cultivator shares in eight different configurations for working depths between 5cm and 30cm. The standard shares are hard-faced, while carbide-coated are available as an optional extra. Angular concave discs sit behind the tines to further mix the soil and straw while helping to level the ground.

Lemken offer its cultivator shares in eight different configurations for working depths between 5cm and 30cm.

A trailing roller is used for soil reconsolidation. Depending on the spec, the working depth is either adjusted manually or via the trailing roller. Prices for the Karat 9 U start from €15,000 plus VAT.

Compact Solitair 9.

Much of Lemken’s range is modular, making it possible to mix and match different seeding combinations with a disc or power harrow configuration.

For those after a high-capacity high-output seed drill, Lemken showcased its Compact Solitair 9.

Although none of these machines has been sold in Ireland for 10 years, Derek noted that the market is changing and going around in a circle, with renewed interest in such a configuration.

Solitair 25.

This drill features hydraulically-adjustable levelling tines, which are followed by individually sprung concave discs.

Staggered wheels with a diameter of 1,064mm (420/65 R20) help to reconsolidate the seed bed. The machine pictured featured a trapeze packer roller for further pre-consolidation of rows directly in front of the double disc coulters.

Lemken says that as the tyre packer roller in front of the trapeze packer roller features large tyres, it has a minimal effect on draft requirement.

Each double-disc coulter has 125cm spacings and is individually guided by a rubber-tyred depth wheel and features up to 70kg of pressure. The 3m drill features two distribution heads with section control.

With a 3,500l tank capacity, time spent loading is significantly reduced compared with the firm’s typical one-pass system, which features a 1,800l hopper.

With an average forward speed in the region of 12km/h to 15km/h achievable on an 180hp tractor, Derek noted that the unit is capable of achieving 30% more output than a power harrow configuration drill. Prices start at €54,000 plus VAT.

Solitair 25.

Another example of Lemken’s modular design is the Solitair 25. This unit is essentially a trailed power harrow with a seed hopper mounted on the chassis and a seeding unit attached via the three-point linkage at the rear.

The option is also there to configure this setup with an eight-row maize seeding unit, with one such setup sold in Co Armagh last year.

The unit is available in working widths from 4m to 6m. The combination on display saw a Zirkon 12-power harrow with a mounted trapeze packer followed by the double-disc seed coulters.

When sowing, the transport wheels tend to ride slightly off the ground.

Solitair 25.

The metering and distribution system on the drill dispenses the seed to four distributor heads via four vertically arranged metering units. Each metering unit is driven by a separate electrical motor. It allows seed rates of 0.5kg/ha to 500kg/ha.

Part width section control is available as standard. The plastic hopper features a 3,000l capacity, while the unit comes with the option of a hydraulically powered filling auger. The 4m complete configuration is priced from €80,000 plus VAT.

Juwel 7 plough.

Precise plough settings are crucial to minimising wear and to reduce fuel consumption.

Lemken claims its Optiquick setting system helps to minimise both. Optiquick can be used to set the front furrow width independently from the tractor/plough pull line. This system is designed to avoid any side forces. By adjusting the turnbuckle, the system works towards pulling the plough through the tractor’s back axle in a straight line.

Lemken’s range of Juwel ploughs are available with 90cm, 100cm or 120cm body spacing. Its basic version allows four different working widths to be set, while the Juwel M V features hydraulic working width adjustment as standard. Using a double-acting hydraulic cylinder, working widths from 30cm to 60cm per body can be set from the tractor seat.

Both the Juwel and the Juwel M V feature a shear pin in the standard specification. The Juwel 7/8 M T and Juwel 7/8 M VT versions feature the hydromatic auto-reset trip device, which enables the plough bodies to move simultaneously upwards and to the side.

Although a solid headboard is available, Derek outlined that 90% of Lemken ploughs in Ireland use slatted headboards, while all feature hydraulically operated depth control.

The Jewel 7 four-furrow starts at €19,900 plus VAT.

Steketee mechanical hoe.

In recent years, we have seen some of the larger European tillage equipment manufacturers either develop their own mechanical weeding equipment or purchase such specialised manufacturing companies.

Three years ago, Lemken purchased Steketee, a Dutch manufacturer of mechanical weeding options. This purchase followed Lemken putting a halt to the production of sprayers.

Although the unit arrived in Ireland earlier this year, last week’s event marked the first Irish public appearance of the inter-row weeder. This particular hoe was configured to work on 1m-wide four double-row carrot beds.

Steketee mechanical hoe.

Each machine can be configured to the specific planter and crop sown, with adjustments easily made on the sliding rails. Various weeding shares, discs, blades, tines or elements can be configured accordingly. The weeder comes with automatic or manual steering systems.

This particular hoe is reliant on camera technology that uses plant imaging. The system works by identifying the desired plant and removing everything else around it, which includes weeds of the wrong shape or colour.

Manual steering can also be used and involves an operator sitting on the seat in the rear of the weeder, manually controlling the machines steering using a joystick.

Row widths from 15cm to 100cm are possible, while working widths of up to 13m are available. Lemken is intending to run a series of farm visits and seminars on the topic over the coming months.

Prices start at €8,000 plus VAT.

SHARING OPTIONS