Joe Morrissey is milking 110 Holstein Friesian cows on a grazing platform of 31ha. He has two leased blocks of land comprising 13ha and 14ha each. The farm is situated in Rostellan, just outside the market town of Midleton in Co Cork. Joe lives on the farm with his wife Olivia and their four kids, Eoghan, Leah, Conor and Daniel.

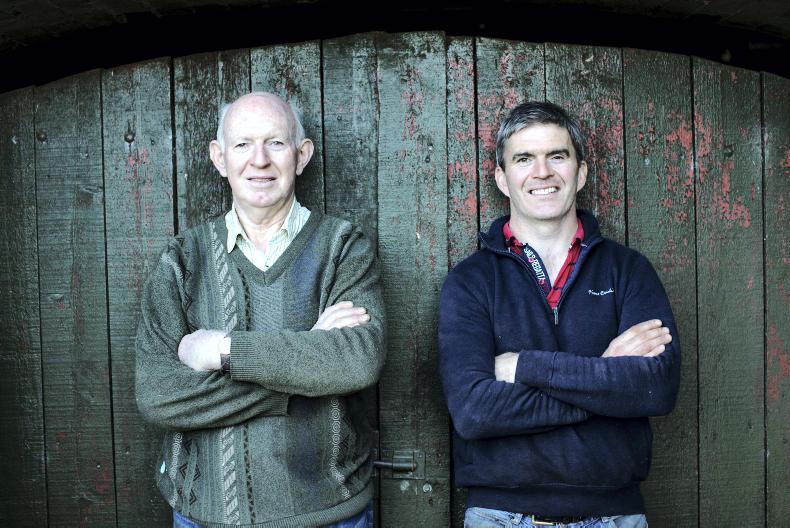

Joe took over the farm from his father Tom who still works on the farm alongside him.

Since taking over the farm from Tom, Joe has been progressive in developing a system that works for him – providing a quality of life and ensuring the farm has a definite direction and long-term sustainability.

Joe has begun focusing his business model around utilising more grass and offsetting the increased labour demand that came when quotas went. He is in the middle of a period of investment for the farm with €200,000 put into handling facilities over the last number of years.

Joe also has plans to upgrade his parlour which is currently a 12-unit herringbone with no ACRs. He has been milk recording since 1994 when he returned home from Kildalton Agricultural College.

“After coming home to farm I suggested that we should go milk recording, so my father came on board and it has progressed the farm no end.”

Joe bringing in the cows with Daniel and Conor.

Balancing progression with workload

As Joe took over the farm from his father, he began to grow the herd and with that came an extra workload. Joe explained how his father always looked after himself and had a healthy work-life balance and following the same philosophy, he has attempted to find ways to increase the output and expansion of the business without overloading himself with work.

His efforts to create an easier and more manageable working environment led to Joe’s involvement in the Lean farming programme with Dairygold. Since starting the programme in 2017, he has made several changes to the systems and operations around the yard. He has replaced an old meal bin which has put a stop to him shovelling 80t of grain a year.

“It is a secondhand one and it is just a push of a button now. It didn’t cost the world, but the saving is priceless.” Using a pedometer to track his steps each day Joe found at peak times on the farm he walks an average of 16km per day. During intensive busy periods, he reaches 21km to 22km per day.

“The pedometer does not consider the side-to-side movement in the parlour. Anything that is wasting time or money needs to be looked at on the farm because time is money. My father and I know the value of rest, so we don’t intend on burning out for the sake of the farm,” Joe says.

The plan is to use the pedometer again this spring and see have the changes he has made around the yard helped in saving him time and effort.

All the cows are 100% AI-bred.

Uniformity key to good production

The breeding on the farm consists of AI with the heifers for three weeks followed by an Angus bull to clean up for the remaining six weeks. The cows are 100% AI-bred with their breeding season lasting for 13 weeks altogether. This has led to Joe having a very high replacement rate of 33% and a young herd. He has been keeping all replacements over the last number of years. He has a six-week calving rate of 80%, which he hopes will continue to increase with his breeding programme.

This year, out of the 41 heifers bred, 40 have scanned in calf and the scanning showed that most of the seemed to have held to the first service. With the large amount of AI on the farm, Joe needs to minimise the amount of labour going to areas with a lower return.

In general, facilities on the farm are good but Joe is still evolving the farm to obtain better cow flow and fluidity in the system. The current parlour needs a revamp as the shed is small and doesn’t allow light into the parlour which restricts cow flow. One side of the standing area is 4in smaller than the other, which is a small thing but does cause an extra few seconds per row to move the cows on.

The plan is to upgrade the parlour to 16-unit with ACRs and generally better specifications than what is currently installed. A new open-plan cubicle shed for 150 cows and feed space for that amount was built in 2008. In 2017, the herd produced 470kg of milk solids on 760kg of meal per cow and has an EBI of 133. The herd is relatively young as the replacement rate is high, but Joe explained he carries a few late-calving cows which will be automatically moved on from the system after calving.

I had to question whether I had too many heifers coming in and the obvious answer was yes

The drought has brought stress on cows and livestock across the country this year and, as a result, Joe has seen a rise in the SCC towards the end of the year. Joe’s response is going to be a severe cull on problem cows after they calve in February. This is where the high replacement rate will come into play. The replacements coming into the herd are of top-AI bulls and will serve the system well.

Speaking about the high replacement rate on the farm, Joe says he has assessed this side of the business.

“I had to question whether I had too many heifers coming in and the obvious answer was yes. However, the next question was, is it justified? The key for the farm is that cows that aren’t going to be working for the system are not kept. This practice of turning the cow around and second-guessing yourself just doesn’t make a lot of sense in my view. It’s not the way to progress the farm and get good uniform standards which is what I’m working towards across the business.”

Machinery on the farm consists of a loading shovel and a Massey Ferguson tractor. The loader is the workhorse of the farm and anything that can be done by machine is done by machine. The old wheelbarrow fell apart a few years ago and Joe didn’t bother buying a new one. All slurry on the grazing platform is applied by a contractor using an umbilical system.

Some slurry spreading is done by Joe but the less he does the better as contracting is just more efficient in general. Joe does his own fertiliser spreading with all the silage also contracted out. An 8ft Kverneland disc mower is used for topping when necessary and knocking some paddocks for bales.

The cubicle shed can hold 150 cows.

Alternatives to meeting fodder deficits

At the end of the summer, Joe was down an estimated 15% on normal grass growth for the year. He had between a 15% and 20% fodder deficit with a second cut to come. In a usual year, the 33ac block supplies all the silage with bales at the shoulders from the grazing platform.

“We are stocked quite high on the milking platform at 3.55 cows/ha, so we are usually buffer feeding silage during the spring and autumn when grass is at its tightest. Therefore, the forage requirement is higher on the farm and the demand for more grass needs to be met on the outblocks.”

The farm is very near the coast and is good grass-growing land. Joe assesses grass every week and estimates the farm to grow 16t Dm/ha on average per year. The quality of swarth is exceptional. He has a slight issue with rust on the farm and you could see that in the grass. Dry weather had stressed the grass and some paddocks were feeling the effects. A good grazing gets rid of the rust, but it is something Joe must be aware of.

“With a stocking rate of 3.55 LU/ha, the farm needs to be growing the amount of grass that it is,” says Joe. “If any year stretched the system, it was this one.”

The good autumn has really helped with rebuilding fodder stocks, Joe says.

“We have a good crop of rape coming through and because growth has remained more than steady we have been able to hold off buffer feeding which usually isn’t the case for us here. While we didn’t have the surplus grass to take third cuts or a lot of bales, the extra grass at the back end of the year was invaluable to easing the pressure,” he says.

Joe has grown rape in conjunction with a tillage farmer for baling this year to alleviate any pressure left with fodder deficits. He baled it in late October with double the netting, and extra wrap of plastic and stacked on the flat. With good weather when cutting, he gave the crop a three-day wilt before baling due to the low dry matter and high nitrates in the crop. He cleared a space in the yard, so he didn’t have to stack them more than one high.

The workshop is neat and tidy.

“The tillage farmer I get the straw off has a good working relationship with us at home so the opportunity to grow it presented itself, and we went for it. I have never baled it myself, but I know how good the feeding is and the cows go mad for it.”

In relation to the large investment on the farm, Joe says the large expenditure over the last 10 years is due to him not wanting to waste time.

“The way I see it is if you don’t spend it then it will probably be taken off you from a tax point of view,” says Joe. He now has feed space for up to 150 cows and an open expansive shed with top-quality handling facilities.

It is already clear that Joe has achieved a very impressive level of production with a very young herd. He is planning for the long term and is focussing on the areas of the farm where he can make the most improvement.

As with any good farming system there is nothing complex or overthought. Practicality and structure stand out throughout the yard. It’s the same with the man running the farm. With strong genetics and a young herd being looked after as well as they are, the sky is the limit for this farm business.

This article first appeared in Irish Dairy Farmer magazine.

Joe Morrissey is milking 110 Holstein Friesian cows on a grazing platform of 31ha. He has two leased blocks of land comprising 13ha and 14ha each. The farm is situated in Rostellan, just outside the market town of Midleton in Co Cork. Joe lives on the farm with his wife Olivia and their four kids, Eoghan, Leah, Conor and Daniel.

Joe took over the farm from his father Tom who still works on the farm alongside him.

Since taking over the farm from Tom, Joe has been progressive in developing a system that works for him – providing a quality of life and ensuring the farm has a definite direction and long-term sustainability.

Joe has begun focusing his business model around utilising more grass and offsetting the increased labour demand that came when quotas went. He is in the middle of a period of investment for the farm with €200,000 put into handling facilities over the last number of years.

Joe also has plans to upgrade his parlour which is currently a 12-unit herringbone with no ACRs. He has been milk recording since 1994 when he returned home from Kildalton Agricultural College.

“After coming home to farm I suggested that we should go milk recording, so my father came on board and it has progressed the farm no end.”

Joe bringing in the cows with Daniel and Conor.

Balancing progression with workload

As Joe took over the farm from his father, he began to grow the herd and with that came an extra workload. Joe explained how his father always looked after himself and had a healthy work-life balance and following the same philosophy, he has attempted to find ways to increase the output and expansion of the business without overloading himself with work.

His efforts to create an easier and more manageable working environment led to Joe’s involvement in the Lean farming programme with Dairygold. Since starting the programme in 2017, he has made several changes to the systems and operations around the yard. He has replaced an old meal bin which has put a stop to him shovelling 80t of grain a year.

“It is a secondhand one and it is just a push of a button now. It didn’t cost the world, but the saving is priceless.” Using a pedometer to track his steps each day Joe found at peak times on the farm he walks an average of 16km per day. During intensive busy periods, he reaches 21km to 22km per day.

“The pedometer does not consider the side-to-side movement in the parlour. Anything that is wasting time or money needs to be looked at on the farm because time is money. My father and I know the value of rest, so we don’t intend on burning out for the sake of the farm,” Joe says.

The plan is to use the pedometer again this spring and see have the changes he has made around the yard helped in saving him time and effort.

All the cows are 100% AI-bred.

Uniformity key to good production

The breeding on the farm consists of AI with the heifers for three weeks followed by an Angus bull to clean up for the remaining six weeks. The cows are 100% AI-bred with their breeding season lasting for 13 weeks altogether. This has led to Joe having a very high replacement rate of 33% and a young herd. He has been keeping all replacements over the last number of years. He has a six-week calving rate of 80%, which he hopes will continue to increase with his breeding programme.

This year, out of the 41 heifers bred, 40 have scanned in calf and the scanning showed that most of the seemed to have held to the first service. With the large amount of AI on the farm, Joe needs to minimise the amount of labour going to areas with a lower return.

In general, facilities on the farm are good but Joe is still evolving the farm to obtain better cow flow and fluidity in the system. The current parlour needs a revamp as the shed is small and doesn’t allow light into the parlour which restricts cow flow. One side of the standing area is 4in smaller than the other, which is a small thing but does cause an extra few seconds per row to move the cows on.

The plan is to upgrade the parlour to 16-unit with ACRs and generally better specifications than what is currently installed. A new open-plan cubicle shed for 150 cows and feed space for that amount was built in 2008. In 2017, the herd produced 470kg of milk solids on 760kg of meal per cow and has an EBI of 133. The herd is relatively young as the replacement rate is high, but Joe explained he carries a few late-calving cows which will be automatically moved on from the system after calving.

I had to question whether I had too many heifers coming in and the obvious answer was yes

The drought has brought stress on cows and livestock across the country this year and, as a result, Joe has seen a rise in the SCC towards the end of the year. Joe’s response is going to be a severe cull on problem cows after they calve in February. This is where the high replacement rate will come into play. The replacements coming into the herd are of top-AI bulls and will serve the system well.

Speaking about the high replacement rate on the farm, Joe says he has assessed this side of the business.

“I had to question whether I had too many heifers coming in and the obvious answer was yes. However, the next question was, is it justified? The key for the farm is that cows that aren’t going to be working for the system are not kept. This practice of turning the cow around and second-guessing yourself just doesn’t make a lot of sense in my view. It’s not the way to progress the farm and get good uniform standards which is what I’m working towards across the business.”

Machinery on the farm consists of a loading shovel and a Massey Ferguson tractor. The loader is the workhorse of the farm and anything that can be done by machine is done by machine. The old wheelbarrow fell apart a few years ago and Joe didn’t bother buying a new one. All slurry on the grazing platform is applied by a contractor using an umbilical system.

Some slurry spreading is done by Joe but the less he does the better as contracting is just more efficient in general. Joe does his own fertiliser spreading with all the silage also contracted out. An 8ft Kverneland disc mower is used for topping when necessary and knocking some paddocks for bales.

The cubicle shed can hold 150 cows.

Alternatives to meeting fodder deficits

At the end of the summer, Joe was down an estimated 15% on normal grass growth for the year. He had between a 15% and 20% fodder deficit with a second cut to come. In a usual year, the 33ac block supplies all the silage with bales at the shoulders from the grazing platform.

“We are stocked quite high on the milking platform at 3.55 cows/ha, so we are usually buffer feeding silage during the spring and autumn when grass is at its tightest. Therefore, the forage requirement is higher on the farm and the demand for more grass needs to be met on the outblocks.”

The farm is very near the coast and is good grass-growing land. Joe assesses grass every week and estimates the farm to grow 16t Dm/ha on average per year. The quality of swarth is exceptional. He has a slight issue with rust on the farm and you could see that in the grass. Dry weather had stressed the grass and some paddocks were feeling the effects. A good grazing gets rid of the rust, but it is something Joe must be aware of.

“With a stocking rate of 3.55 LU/ha, the farm needs to be growing the amount of grass that it is,” says Joe. “If any year stretched the system, it was this one.”

The good autumn has really helped with rebuilding fodder stocks, Joe says.

“We have a good crop of rape coming through and because growth has remained more than steady we have been able to hold off buffer feeding which usually isn’t the case for us here. While we didn’t have the surplus grass to take third cuts or a lot of bales, the extra grass at the back end of the year was invaluable to easing the pressure,” he says.

Joe has grown rape in conjunction with a tillage farmer for baling this year to alleviate any pressure left with fodder deficits. He baled it in late October with double the netting, and extra wrap of plastic and stacked on the flat. With good weather when cutting, he gave the crop a three-day wilt before baling due to the low dry matter and high nitrates in the crop. He cleared a space in the yard, so he didn’t have to stack them more than one high.

The workshop is neat and tidy.

“The tillage farmer I get the straw off has a good working relationship with us at home so the opportunity to grow it presented itself, and we went for it. I have never baled it myself, but I know how good the feeding is and the cows go mad for it.”

In relation to the large investment on the farm, Joe says the large expenditure over the last 10 years is due to him not wanting to waste time.

“The way I see it is if you don’t spend it then it will probably be taken off you from a tax point of view,” says Joe. He now has feed space for up to 150 cows and an open expansive shed with top-quality handling facilities.

It is already clear that Joe has achieved a very impressive level of production with a very young herd. He is planning for the long term and is focussing on the areas of the farm where he can make the most improvement.

As with any good farming system there is nothing complex or overthought. Practicality and structure stand out throughout the yard. It’s the same with the man running the farm. With strong genetics and a young herd being looked after as well as they are, the sky is the limit for this farm business.

This article first appeared in Irish Dairy Farmer magazine.

SHARING OPTIONS