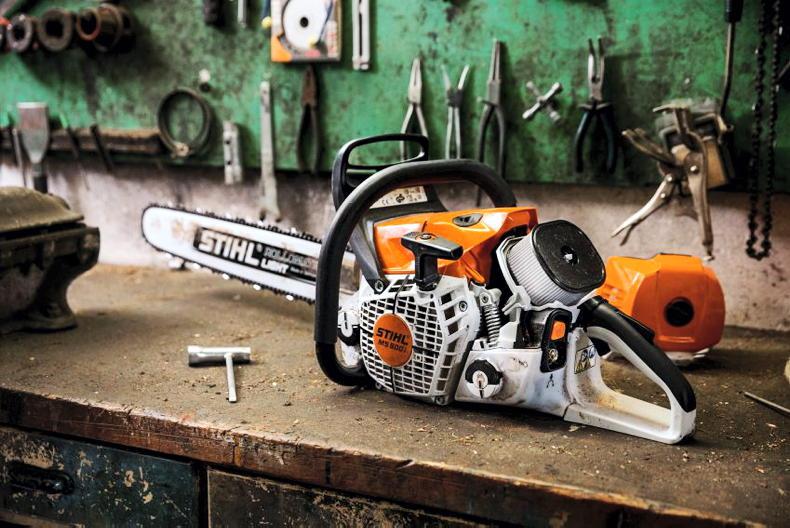

On most Irish farms, a chainsaw is a seasonal tool that’s taken out of the workshop and expected to perform at the first pull of the cord. Despite being a relatively small and simple tool, routine servicing is essential if top performance is to be achieved by both the engine and cutting blade. Here we offer some practical maintenance tips on how to get the best out of your chainsaw, starting with the engine.

Spark plugs

If the chainsaw requires numerous pulls of the cord to start or even fails to start then there’s a good chance the spark plug needs to be replaced. Remove the top cover and then remove the spark plug and examine its condition. If the porcelain insulator is cracked, an electrode may be damaged or burnt or there may even be a build-up of carbon.

Sparks plugs are relatively inexpensive and should be replaced at every service.

These are all signs that it needs to be replaced. A replacement spark plug will only cost €5-€10, so annual replacement is advised.

A grey colouring on the used plug may indicate piston damage. This discolouration can be the result of aluminium burning in the cylinder.

When starting from cold, use the air purge device, if fitted. This fills the fuel line and carburettor with fuel and pushes the air out, allowing the engine to start quicker. From here, switch on and pull on the choke. Pull the start cord until the engine fires, then disengage the choke. If the saw fails to start first time and you proceed to pull one or two more times with the choke out, you will flood the saw. Now, let off the choke and pull – it should start.

Spark plugs that show signs of carbon build up or have a burnt appearance need to be replaced.

Engine flooding occurs when petrol gets in the compression chamber before it ignites. This stagnant petrol prevents the spark and ignition of the engine. Therefore, it must be drained from the system beforehand. The best way to do this is through persistent, repeated attempts, yanking the pull cord with the saw switched off. Once you get it to start, run the saw until it clears itself of the heavy exhaust fumes from the flooded engine.

Storage and filters

Most saws are left sitting up for a long period with fuel in the tank. Ideally, the tank should be left empty over long periods to prevent the two-stroke fuel mix ingredients evaporating, leaving behind a jelly-like substance. This can clog the carburettor. Carburettor cleaner will resolve the issue in most instances, but in the worst-case scenario the carburettor may need to be rebuilt or replaced.

Every service should see the fuel filter replaced as it’s not uncommon for small dust particles to make their way into the fuel tank while removing the filler cap or while refuelling. A new filter will typically range between €5 and €10.

Not only should the air filter be replaced at every service but it should also frequently cleaned out.

The air filter should also be replaced at least every service but also removed and cleaned out frequently over a day’s cutting, especially in a dusty environment. A blocked air filter will result in restricted power as the engine is receiving too much fuel and not enough air. Air vents should be kept clear so that air intake is not restricted, otherwise the saw may overheat.

A replacement fuel filter will range between €5 and €10 and should also be replaced at every service.

Guide bar and sprocket

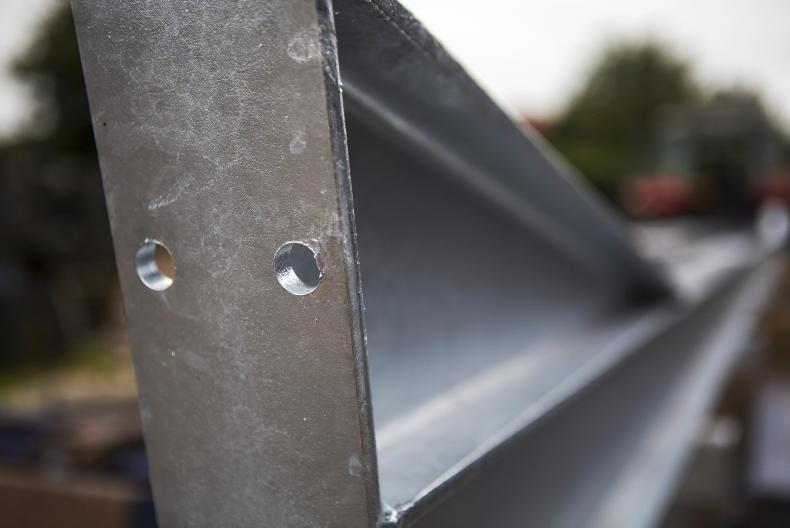

Often the chain receives all the attention and the guide bar is overlooked. Therefore, examine the track on which the chain runs – it needs to be kept clean if the chain oil is to lubricate the chain properly. The chain guide bar is fitted with a bearing and sprocket.

The chain guide bar should be removed and examined for wear and then either replaced or turned depending on its condition.

This bearing, like any bearing, should receive grease regularly. The guide bar is a wearing part. If the chain channel has widened enough that the chain has become loose, then it will need to be replaced or turned upside down. The top side will naturally wear more, so when wear just about becomes visible it is often a good idea to turn the guide bar upside down to get that lifespan before replacement.

There is a bearing inside the guide bar which should be greased regularly.

Chain and sharpening

The quantity and more importantly the type of timber being cut, will determine how long a chain will stay sharp. If the chain comes into contact with clay/stones, it will immediately lose its edge. As a rule of thumb, if leaning is required to make the saw cut, then it is in need of sharpening. A properly sharpened saw should guide its own way through timber.

The chain track needs to be clean to allow oil to lubricate the chain properly.

A chain can be sharpened manually with a file or using an electric sharpener. An electric sharpener may be quicker, but a simple round file or two-in-one tool is handy when out and about, eliminating the need to return to the yard or have it professionally sharpened. The two-in-one tool sharpens both the cutters and depth gauge (rakers) simultaneously.

A two-in-one sharpening tool is a handy device.

But first, identify the chain type which in turn determines the size of file needed and the angle at which the chain is to be sharpened. This method requires some skill and patience to perfect. A chain that has been sharpened unevenly will not cut straight and will wear unevenly. Each tooth has a witness mark on the top, which has two functions. Firstly, it indicates the sharpening angle and secondly, it marks the end of the chain’s life when filed to this point.

To sharpen, the file should be held level and at the correct angle. It then needs to be drawn from the inside of the cutter to the outside of the cutter with an equal number of rubs for each cutter to ensure the chain is evenly sharpened and worn. As a chain is sharpened, its depth gauges need to be lowered. Too low and the saw will be biting too much into the timber, causing it to jump, and if too high, the chainsaw will be unable to cut the timber. The two-in-one tool lowers the rakers automatically while sharpening. If in doubt, it may be worthwhile having the chain professionally sharpened.

It is critically important that the correct PPE is worn.

A replacement chain will cost in the region of €25 to €30 depending on brand and size. Chain tension is important – too tight and it will not move freely on the guide bar, too loose and it has the possibility of coming off the guide bar. It should be tightened to the point that it is just resting against the bottom side of the guide bar. Frequently check and adjust the tension if necessary.

Chain oil

A common error made is that proper chain oil is not used. Waste oil or any oils such as engine or hydraulic oil should not be used, as they do not have the proper cling qualities and therefore are flung straight off the chain. Dedicated chain oil is relatively inexpensive considering the quantity used. Generally, the ratio of fuel usage to chain oil should be 1:1.

Chain brake

The chain brake is a critical safety feature on any chainsaw and needs to be functional. This is simply a steel band around the saw’s clutch drum. Once activated, rotation of the chain stops immediately. It is good practice to apply the brake every time the saw is left down or not in use. A saw with no chain brake should not be used.

Replace spark plug, air and fuel filters during every service, cleaning air filters frequently during use.Inspect guide bar for wear.A sharp chain should guide its own way through timber.Use the correct file while sharpening, always drawing away from yourself. Keep both repetitions and angle equal to the witness mark on each tooth.Check chain tension and chain brake functionality frequently.Always ensure the correct Personal Protective Equipment (PPE) is worn.

On most Irish farms, a chainsaw is a seasonal tool that’s taken out of the workshop and expected to perform at the first pull of the cord. Despite being a relatively small and simple tool, routine servicing is essential if top performance is to be achieved by both the engine and cutting blade. Here we offer some practical maintenance tips on how to get the best out of your chainsaw, starting with the engine.

Spark plugs

If the chainsaw requires numerous pulls of the cord to start or even fails to start then there’s a good chance the spark plug needs to be replaced. Remove the top cover and then remove the spark plug and examine its condition. If the porcelain insulator is cracked, an electrode may be damaged or burnt or there may even be a build-up of carbon.

Sparks plugs are relatively inexpensive and should be replaced at every service.

These are all signs that it needs to be replaced. A replacement spark plug will only cost €5-€10, so annual replacement is advised.

A grey colouring on the used plug may indicate piston damage. This discolouration can be the result of aluminium burning in the cylinder.

When starting from cold, use the air purge device, if fitted. This fills the fuel line and carburettor with fuel and pushes the air out, allowing the engine to start quicker. From here, switch on and pull on the choke. Pull the start cord until the engine fires, then disengage the choke. If the saw fails to start first time and you proceed to pull one or two more times with the choke out, you will flood the saw. Now, let off the choke and pull – it should start.

Spark plugs that show signs of carbon build up or have a burnt appearance need to be replaced.

Engine flooding occurs when petrol gets in the compression chamber before it ignites. This stagnant petrol prevents the spark and ignition of the engine. Therefore, it must be drained from the system beforehand. The best way to do this is through persistent, repeated attempts, yanking the pull cord with the saw switched off. Once you get it to start, run the saw until it clears itself of the heavy exhaust fumes from the flooded engine.

Storage and filters

Most saws are left sitting up for a long period with fuel in the tank. Ideally, the tank should be left empty over long periods to prevent the two-stroke fuel mix ingredients evaporating, leaving behind a jelly-like substance. This can clog the carburettor. Carburettor cleaner will resolve the issue in most instances, but in the worst-case scenario the carburettor may need to be rebuilt or replaced.

Every service should see the fuel filter replaced as it’s not uncommon for small dust particles to make their way into the fuel tank while removing the filler cap or while refuelling. A new filter will typically range between €5 and €10.

Not only should the air filter be replaced at every service but it should also frequently cleaned out.

The air filter should also be replaced at least every service but also removed and cleaned out frequently over a day’s cutting, especially in a dusty environment. A blocked air filter will result in restricted power as the engine is receiving too much fuel and not enough air. Air vents should be kept clear so that air intake is not restricted, otherwise the saw may overheat.

A replacement fuel filter will range between €5 and €10 and should also be replaced at every service.

Guide bar and sprocket

Often the chain receives all the attention and the guide bar is overlooked. Therefore, examine the track on which the chain runs – it needs to be kept clean if the chain oil is to lubricate the chain properly. The chain guide bar is fitted with a bearing and sprocket.

The chain guide bar should be removed and examined for wear and then either replaced or turned depending on its condition.

This bearing, like any bearing, should receive grease regularly. The guide bar is a wearing part. If the chain channel has widened enough that the chain has become loose, then it will need to be replaced or turned upside down. The top side will naturally wear more, so when wear just about becomes visible it is often a good idea to turn the guide bar upside down to get that lifespan before replacement.

There is a bearing inside the guide bar which should be greased regularly.

Chain and sharpening

The quantity and more importantly the type of timber being cut, will determine how long a chain will stay sharp. If the chain comes into contact with clay/stones, it will immediately lose its edge. As a rule of thumb, if leaning is required to make the saw cut, then it is in need of sharpening. A properly sharpened saw should guide its own way through timber.

The chain track needs to be clean to allow oil to lubricate the chain properly.

A chain can be sharpened manually with a file or using an electric sharpener. An electric sharpener may be quicker, but a simple round file or two-in-one tool is handy when out and about, eliminating the need to return to the yard or have it professionally sharpened. The two-in-one tool sharpens both the cutters and depth gauge (rakers) simultaneously.

A two-in-one sharpening tool is a handy device.

But first, identify the chain type which in turn determines the size of file needed and the angle at which the chain is to be sharpened. This method requires some skill and patience to perfect. A chain that has been sharpened unevenly will not cut straight and will wear unevenly. Each tooth has a witness mark on the top, which has two functions. Firstly, it indicates the sharpening angle and secondly, it marks the end of the chain’s life when filed to this point.

To sharpen, the file should be held level and at the correct angle. It then needs to be drawn from the inside of the cutter to the outside of the cutter with an equal number of rubs for each cutter to ensure the chain is evenly sharpened and worn. As a chain is sharpened, its depth gauges need to be lowered. Too low and the saw will be biting too much into the timber, causing it to jump, and if too high, the chainsaw will be unable to cut the timber. The two-in-one tool lowers the rakers automatically while sharpening. If in doubt, it may be worthwhile having the chain professionally sharpened.

It is critically important that the correct PPE is worn.

A replacement chain will cost in the region of €25 to €30 depending on brand and size. Chain tension is important – too tight and it will not move freely on the guide bar, too loose and it has the possibility of coming off the guide bar. It should be tightened to the point that it is just resting against the bottom side of the guide bar. Frequently check and adjust the tension if necessary.

Chain oil

A common error made is that proper chain oil is not used. Waste oil or any oils such as engine or hydraulic oil should not be used, as they do not have the proper cling qualities and therefore are flung straight off the chain. Dedicated chain oil is relatively inexpensive considering the quantity used. Generally, the ratio of fuel usage to chain oil should be 1:1.

Chain brake

The chain brake is a critical safety feature on any chainsaw and needs to be functional. This is simply a steel band around the saw’s clutch drum. Once activated, rotation of the chain stops immediately. It is good practice to apply the brake every time the saw is left down or not in use. A saw with no chain brake should not be used.

Replace spark plug, air and fuel filters during every service, cleaning air filters frequently during use.Inspect guide bar for wear.A sharp chain should guide its own way through timber.Use the correct file while sharpening, always drawing away from yourself. Keep both repetitions and angle equal to the witness mark on each tooth.Check chain tension and chain brake functionality frequently.Always ensure the correct Personal Protective Equipment (PPE) is worn.

SHARING OPTIONS