Tom and Maura Murphy, along with their sons Patrick and Philip, are all part of the family dairy enterprise. The Swiftsheath herd is based near Jenkinstown, Co Kilkenny, and is currently milking 110 pedigree Holstein cows.

Philip Murphy, Jenkinstown, Co Kilkenny.

Given the nature of any high-yielding Holstein herd, if cows are to properly perform then feed management in terms of diet is crucial.

Earlier this year, the Murphys opted for the Cowconnect diet feeder feed management tool to help with all aspects of feeding, essentially streamlining the feeding process while gathering more data in terms of feed mixes, costings, etc. Benefits include the live tracking of feed costs and the ability to formulate/update rations on the go via the Cowconnect mobile app.

Any updates or changes are instantly saved and available to all connected devices including the displays inside the diet feeder tractor or loader. Regardless of whether the operator is up to date with the ration ingredients or not, by clicking on the particular ration required, they will be guided step by step through each ingredient quantity.

Background

In 2016, the decision was made to go down the robotic milking route for a number of reasons, which the family feels has been a great decision. They started out with one unit. The second Lely Astronaut was commissioned last year. The Murphys operate an A-B-C grazing system with the plan not to house cattle until November but in the meantime slowly ramp up buffer feeding with a TMR. As a result, the diet feeder is a regularly used machine on the farm. With the abundance of data harvested from the robots, the lads wanted to drive insights into the feed management side of things.

Before switching to the Cowconnect system, rations were formulated by the farm’s nutritionist and passed on, before being recorded on paper and placed in the tractor and loader, or recalled from memory. This meant whether it was either Tom, Patrick or Philip feeding, everyone had to be up to speed with the current ration and even more so if two rations were being fed at once, ie heifer diet and milking cow diet. If the number of cows being fed changed in a particular pen then this had to be taken into account when loading ingredients. The previous Digi-Star box fitted on the diet feeder only offered basic weight readings, with little or no flexibility to store rations, let alone offer mobile or cloud connectivity.

How it works

Having heard about the Cowconnect box, Philip explained how it proved to be a unique solution on the market, keeping simplicity in mind.

Philip ordered the box and fitted it himself. “It was just a matter of removing the old box, mounting the Cowconnect box and plugging in the two existing cables, one for power and the other for the weigh cells. Once that was done, it was a matter of pairing the two remote displays which work over Wi-Fi. We went for two mobile phones, one mounted in the loader tractor and the other in the tractor on the diet feeder. The monthly subscription is taken care of via direct debit payments.”

The box is fitted with a sim card and Wi-Fi module for the upload and download of realtime data to the cloud as well as communication with the mobile devices in the cabs. Philip explained how any number of devices can be connected to the one Cowconnect box once permission is granted. For example, Tom, Patrick and Philip along with the farm nutritionist all have access to the app through their mobile devices or PCs. Using the app, the required ration can be edited or formulated on the go.

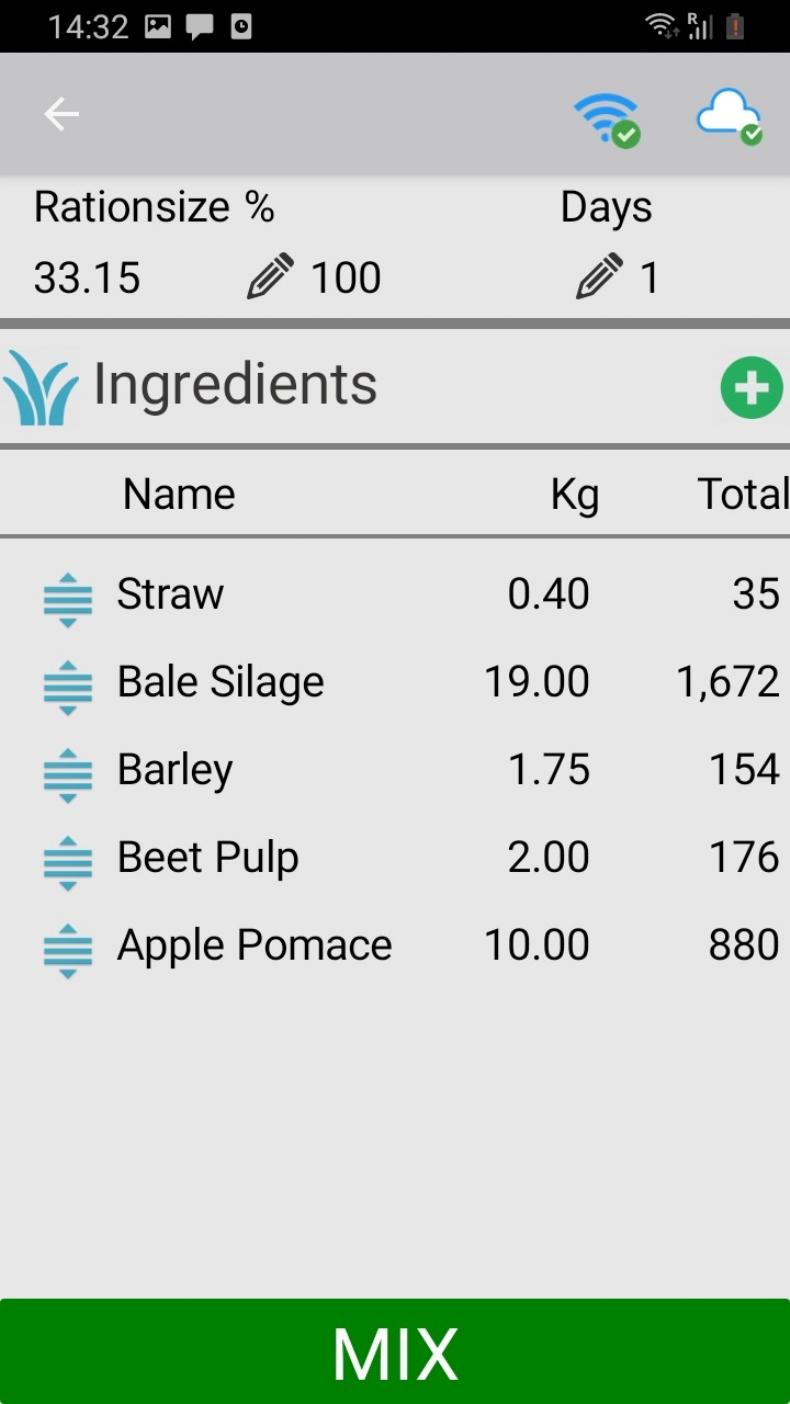

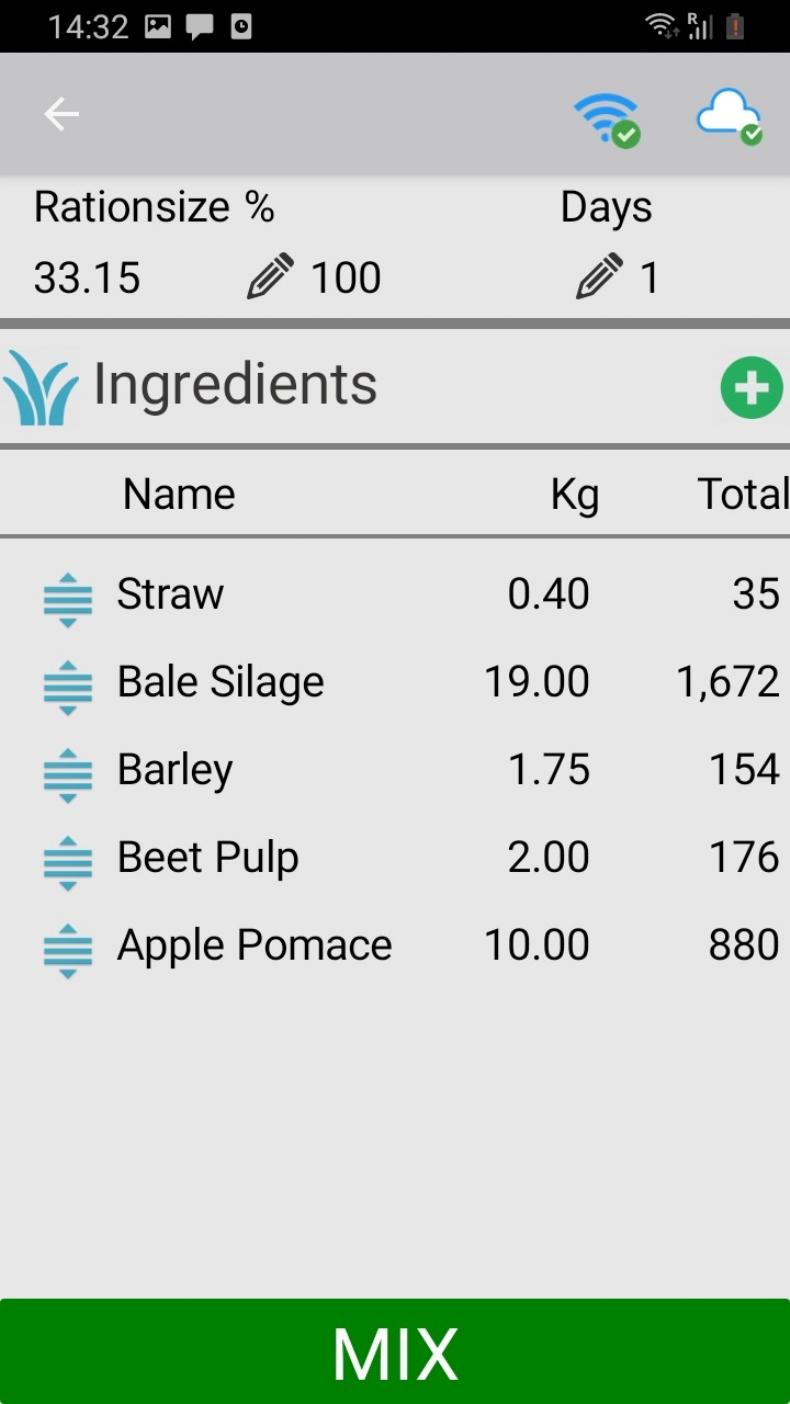

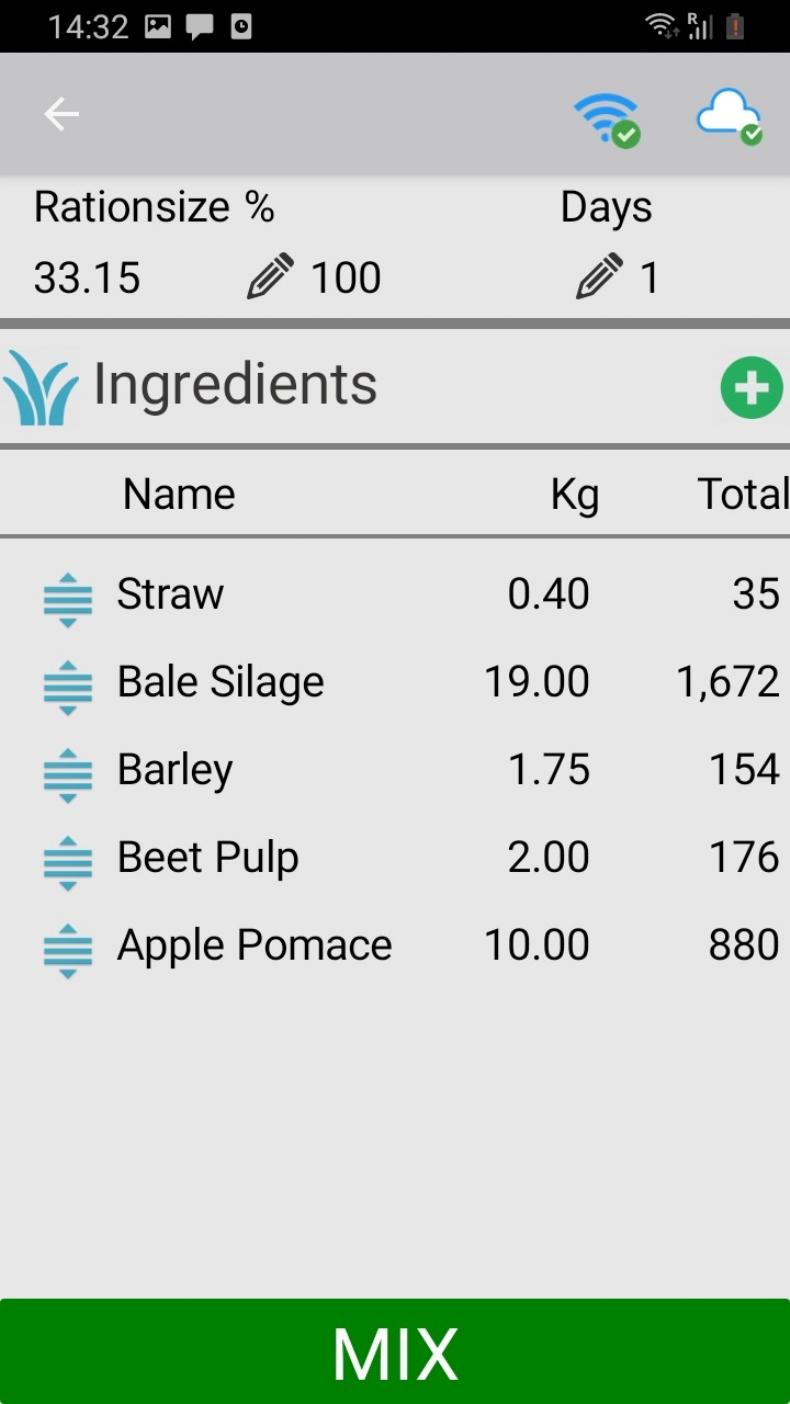

The number of cattle to feed, ration ingredients and their associated quantities are all inputted.

Once the particular diet and number of cows have been selected, the screen will display the first ingredient, prompting the loader driver to fill the diet feeder with the particular amount of feed stuff. As the silage, for example, is tipped into the feeder, the quantity in kilos yet to be loaded decreases. The next ingredient will appear in a similar fashion and count down until the required amount is placed in the feeder. Depending on the number of ingredients, this will continue until the recipe is complete.

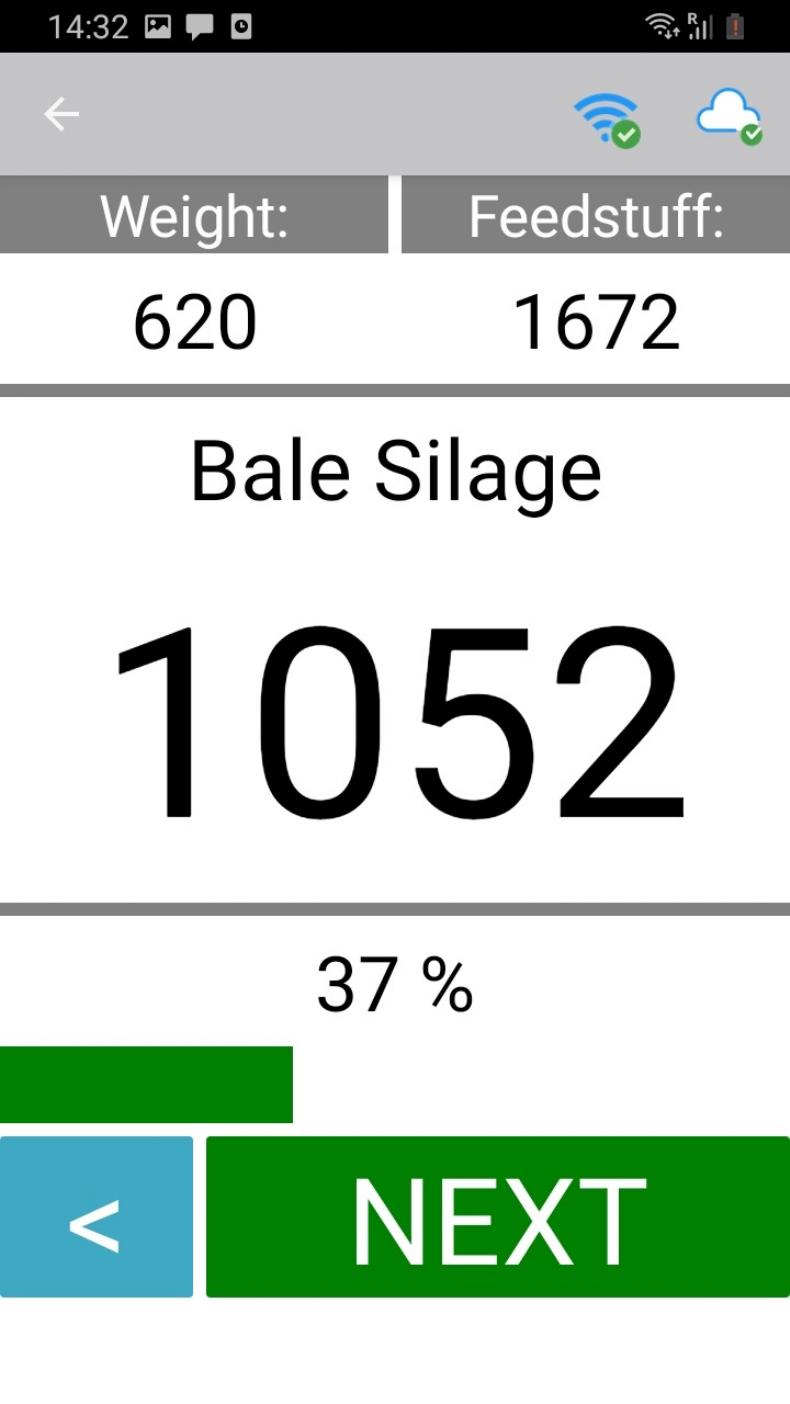

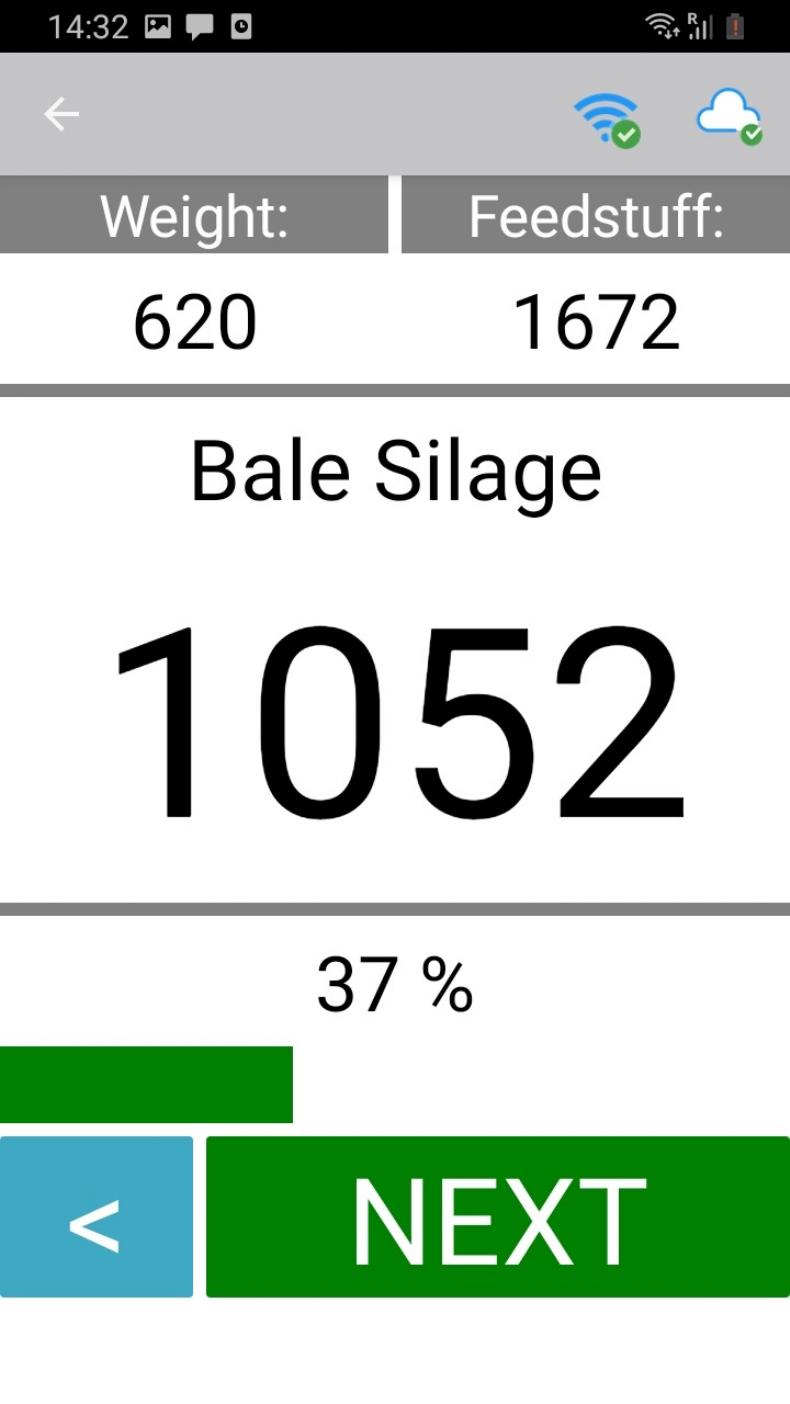

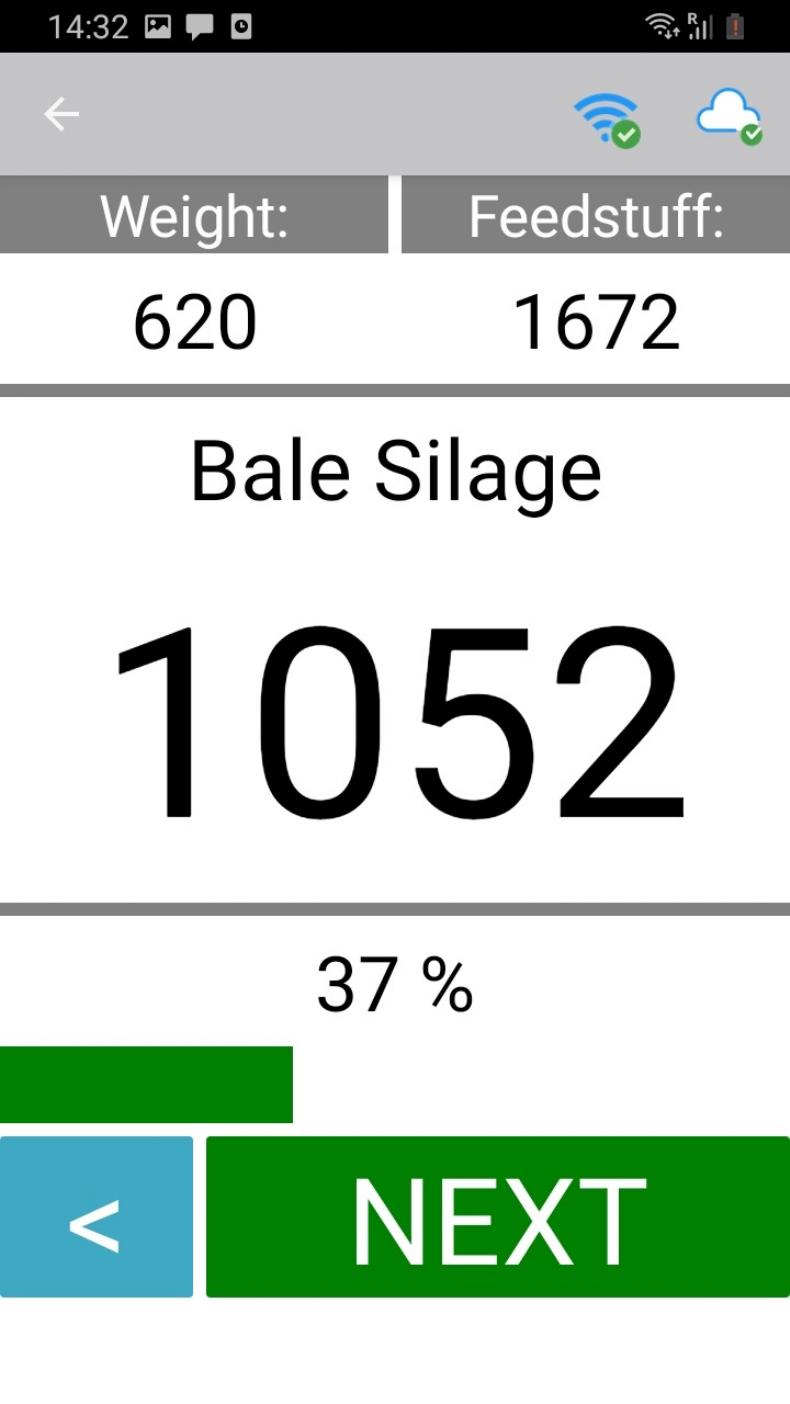

As each ingredient is loaded its total weight in kilos works back to zero as shown.

If too much or too little is loaded into the feeder, then it is recorded and logged with an associated cost. Associated load data including costing is recorded on the Feeding Portal for analysis.

“In some ways, you could say it forces accuracy, when you can see in euros the extra expense of loading inaccuracies, you really start making an effort to get ingredient weights right.

When feeding out, the remaining weight left in the feeder is displayed.

“For example, 10kg too much barley may not sound like much in a 3t mix, but over time if this was to keep happening daily it works out into a substantial cost. It also means we can feed exactly what is advised for completely accurate results,” Philip explained.

Plans and other features

Three plans are available, with the Lite plan suiting the majority of farmers. This €29/month plan covers sim card costs, updates, cloud storage and product support. The more costly €59/month Pro and €79/month Premium plans are available which include additional modules such as Stock Control and parlour integrations .

The Feeding Portal is offered with all plans, although on the more expensive plans there are more features and functions. As mentioned, the Feeding Portal is where feed costs and ingredient usage can be analysed historically and in real time.

The Cowconnect platform has helped with feed management in more ways than one, Philip explained.

“The pen and paper in the tractor cab are done away with. Whoever is feeding can simply hop up on the loader tractor and fill the feeder even if they are not familiar with the diet. The savings alone of eliminating feed inaccuracies will have justified the price of the system before too long. Not only can we see our costings better now, but our nutritionist has access to all our feed records and has the ability to analyse these in line with milk yields, etc. As a result, we can all make more accurate decisions based on this data.

The Murphy's New Holland T6080 and FeedAll diet feeder.

“Eventually, we would like to get to the point where our Cowconnect box could communicate closer with the Lely Astronauts and have a fully connected system where decisions in terms of feed could automatically be made based on herd yields, for example.”

That said, Cowconnect has the ability to integrate with some herd management systems analyzing both inputs in terms of feed and output in terms of yield and create management reports as result.

The complete plug and play box is priced at € 2,500 plus VAT or €3,500 plus VAT with two tablets for remote display and control purposes. A subscription based on one of the three plans is then paid monthly.

Cowconnect

Cowconnect is a Danish company specialising in the area of feed management. The firm, which was founded in 2017, is now part of the AB Agri business division called Intellync. Cowconnect offers a range of cloud and app packages for weighing and feed management purposes. The majority of its offerings are predominantly software- and cloud-based, the only hardware involved being a plug and play terminal.

Although Cowconnect remains an unheard-of name within the Irish farming community for now, the company has a strong presence in over 10 European counties including the UK. There are currently eight developers based in Ireland, with the future plans to grow the Irish market. For now, both Trioliet and Strautmann are Cowconnect partners and can offer the platform to customers. Speaking with the company’s representatives in Ireland, the plan going forward is to get more manufacturers on board as well as sell solutions directly to the farmer.

Tom and Maura Murphy, along with their sons Patrick and Philip, are all part of the family dairy enterprise. The Swiftsheath herd is based near Jenkinstown, Co Kilkenny, and is currently milking 110 pedigree Holstein cows.

Philip Murphy, Jenkinstown, Co Kilkenny.

Given the nature of any high-yielding Holstein herd, if cows are to properly perform then feed management in terms of diet is crucial.

Earlier this year, the Murphys opted for the Cowconnect diet feeder feed management tool to help with all aspects of feeding, essentially streamlining the feeding process while gathering more data in terms of feed mixes, costings, etc. Benefits include the live tracking of feed costs and the ability to formulate/update rations on the go via the Cowconnect mobile app.

Any updates or changes are instantly saved and available to all connected devices including the displays inside the diet feeder tractor or loader. Regardless of whether the operator is up to date with the ration ingredients or not, by clicking on the particular ration required, they will be guided step by step through each ingredient quantity.

Background

In 2016, the decision was made to go down the robotic milking route for a number of reasons, which the family feels has been a great decision. They started out with one unit. The second Lely Astronaut was commissioned last year. The Murphys operate an A-B-C grazing system with the plan not to house cattle until November but in the meantime slowly ramp up buffer feeding with a TMR. As a result, the diet feeder is a regularly used machine on the farm. With the abundance of data harvested from the robots, the lads wanted to drive insights into the feed management side of things.

Before switching to the Cowconnect system, rations were formulated by the farm’s nutritionist and passed on, before being recorded on paper and placed in the tractor and loader, or recalled from memory. This meant whether it was either Tom, Patrick or Philip feeding, everyone had to be up to speed with the current ration and even more so if two rations were being fed at once, ie heifer diet and milking cow diet. If the number of cows being fed changed in a particular pen then this had to be taken into account when loading ingredients. The previous Digi-Star box fitted on the diet feeder only offered basic weight readings, with little or no flexibility to store rations, let alone offer mobile or cloud connectivity.

How it works

Having heard about the Cowconnect box, Philip explained how it proved to be a unique solution on the market, keeping simplicity in mind.

Philip ordered the box and fitted it himself. “It was just a matter of removing the old box, mounting the Cowconnect box and plugging in the two existing cables, one for power and the other for the weigh cells. Once that was done, it was a matter of pairing the two remote displays which work over Wi-Fi. We went for two mobile phones, one mounted in the loader tractor and the other in the tractor on the diet feeder. The monthly subscription is taken care of via direct debit payments.”

The box is fitted with a sim card and Wi-Fi module for the upload and download of realtime data to the cloud as well as communication with the mobile devices in the cabs. Philip explained how any number of devices can be connected to the one Cowconnect box once permission is granted. For example, Tom, Patrick and Philip along with the farm nutritionist all have access to the app through their mobile devices or PCs. Using the app, the required ration can be edited or formulated on the go.

The number of cattle to feed, ration ingredients and their associated quantities are all inputted.

Once the particular diet and number of cows have been selected, the screen will display the first ingredient, prompting the loader driver to fill the diet feeder with the particular amount of feed stuff. As the silage, for example, is tipped into the feeder, the quantity in kilos yet to be loaded decreases. The next ingredient will appear in a similar fashion and count down until the required amount is placed in the feeder. Depending on the number of ingredients, this will continue until the recipe is complete.

As each ingredient is loaded its total weight in kilos works back to zero as shown.

If too much or too little is loaded into the feeder, then it is recorded and logged with an associated cost. Associated load data including costing is recorded on the Feeding Portal for analysis.

“In some ways, you could say it forces accuracy, when you can see in euros the extra expense of loading inaccuracies, you really start making an effort to get ingredient weights right.

When feeding out, the remaining weight left in the feeder is displayed.

“For example, 10kg too much barley may not sound like much in a 3t mix, but over time if this was to keep happening daily it works out into a substantial cost. It also means we can feed exactly what is advised for completely accurate results,” Philip explained.

Plans and other features

Three plans are available, with the Lite plan suiting the majority of farmers. This €29/month plan covers sim card costs, updates, cloud storage and product support. The more costly €59/month Pro and €79/month Premium plans are available which include additional modules such as Stock Control and parlour integrations .

The Feeding Portal is offered with all plans, although on the more expensive plans there are more features and functions. As mentioned, the Feeding Portal is where feed costs and ingredient usage can be analysed historically and in real time.

The Cowconnect platform has helped with feed management in more ways than one, Philip explained.

“The pen and paper in the tractor cab are done away with. Whoever is feeding can simply hop up on the loader tractor and fill the feeder even if they are not familiar with the diet. The savings alone of eliminating feed inaccuracies will have justified the price of the system before too long. Not only can we see our costings better now, but our nutritionist has access to all our feed records and has the ability to analyse these in line with milk yields, etc. As a result, we can all make more accurate decisions based on this data.

The Murphy's New Holland T6080 and FeedAll diet feeder.

“Eventually, we would like to get to the point where our Cowconnect box could communicate closer with the Lely Astronauts and have a fully connected system where decisions in terms of feed could automatically be made based on herd yields, for example.”

That said, Cowconnect has the ability to integrate with some herd management systems analyzing both inputs in terms of feed and output in terms of yield and create management reports as result.

The complete plug and play box is priced at € 2,500 plus VAT or €3,500 plus VAT with two tablets for remote display and control purposes. A subscription based on one of the three plans is then paid monthly.

Cowconnect

Cowconnect is a Danish company specialising in the area of feed management. The firm, which was founded in 2017, is now part of the AB Agri business division called Intellync. Cowconnect offers a range of cloud and app packages for weighing and feed management purposes. The majority of its offerings are predominantly software- and cloud-based, the only hardware involved being a plug and play terminal.

Although Cowconnect remains an unheard-of name within the Irish farming community for now, the company has a strong presence in over 10 European counties including the UK. There are currently eight developers based in Ireland, with the future plans to grow the Irish market. For now, both Trioliet and Strautmann are Cowconnect partners and can offer the platform to customers. Speaking with the company’s representatives in Ireland, the plan going forward is to get more manufacturers on board as well as sell solutions directly to the farmer.

SHARING OPTIONS