A new 198-cubicle shed has recently been installed on the farm of Gerard and Emer Howard from just outside of Fermoy in Co Cork. The farm has steadily increased numbers since quotas went, moving from 80 to 140 cows.

However, with limited winter accommodation on the farm it meant that other sheds had to be rented away from the home yard. This meant a lot of time was spent on the road feeding cattle. The new shed was seen as key to reducing workload for the farm, with all stock now located in the one central yard.

“We were renting sheds away from the yard last year and some of them were within 5km of the farm but others were up on 20km away which could take three hours to feed,” Gerard explained.

The farm brings all youngstock through to slaughter, while also buying in additional calves to finish too. Therefore at any one time the shed could be accommodating cows, replacement heifers and cattle for finishing.

“We are happy at the numbers we have now,” Emer explained, “If we went up more numbers then it would just mean that we would have to hire in more labour, which is not what we want.”

Gerard added: “I like the beef. It’s good to have it (the beef) in a year when the milk price is bad and it helps not to have all your eggs in one basket. We like having a variety. It adds to the bottom line at the end of the day and we can make a good income from them.”

The shed/ch>

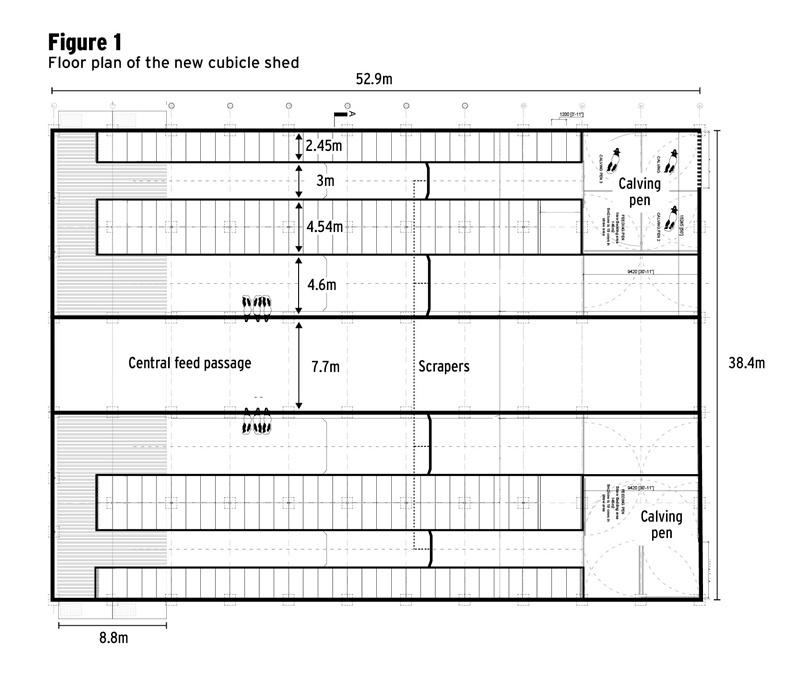

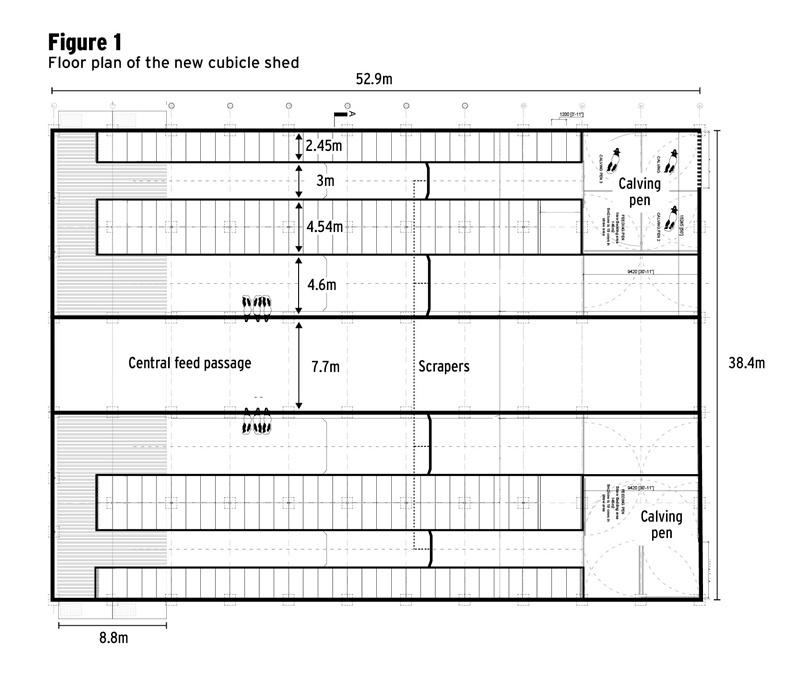

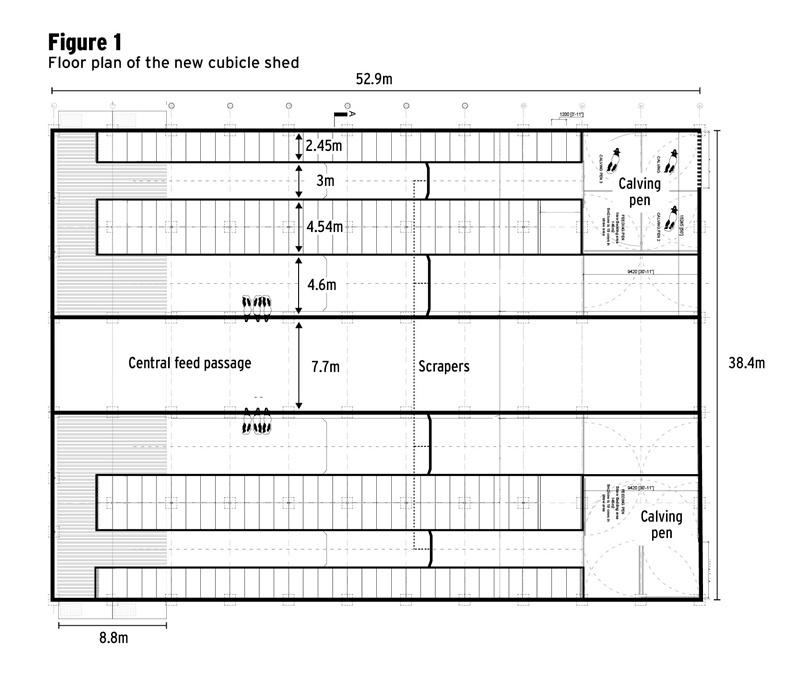

The shed is 52.9m long and 38.4m wide with a feed passage running down through the centre of the shed. A 7.7m-wide central feed passage was decided on to ensure plenty of room to accommodate the diet feeder. The shed stands at 4.5m to the eaves, rising to 10.4m at the apex of the ridge cap. The roof has a 15° slope.

The shed is used to hold beef cattle as well as cows, and while all cows will be stocked at one cow/cubicle, for the beef stock higher stocking rates are used. The shed will generally be used to hold over 200 cattle at any one time.

Cattle are fed along one end of the shed to provide additional space. “About 220 can eat at the one time if we needed, with the extra feed space at either end,” according to Gerard. Total length of available feed face is approximately 136m, which if used to accommodate 200 cattle would mean space of 680mm/animal.

Inlet ventilation is provided through a combination of vented sheeting and a continuous opening running directly below the eaves. As the shed is over 24m wide then a continuous opening of 450mm is required in addition to the vented sheeting.

“We are happy with the movement of air throughout the shed, but you do need the opening,” according to Gerard.

Excluding the central feed passage, area within the shed is 8m2 per cow, at 200 cows.

Cubicles

A three-row cubicle design was chosen for each side of the shed. Crossover points, fitted with tip-over drinkers, are in place at either end of the row of cubicles. Cubicles along the wall measure 2.45m while the head-to-head cubicles are 2.27m long each. The back passage of the shed is 3m wide while the front passage, along the feed barrier, is 4.6m wide. The wide passage along the feed barrier is in a bid to reduce bullying of young or smaller cows.

“We went with the diagonal feed barriers as it means that we can feed bales of silage or zero-grazed grass without worrying about it being pulled into the passageways,” Gerard explained.

“We had originally costed to just have a straight bar in but we said when we were doing it that we would do it once and do it right.”

Two bays are dedicated to a calving area within the shed, with a 146m2 straw bedded area on either side of the feed passage. Each pen is fitted with a calving gate while the gates at the front of the calving pen have been designed so that cows can be given access to one or two spans of the feed barrier. This means that if there are two cows in the calving pen they will not be taking up potentially where 18 cows could feed.

Slurry

Dairymaster scrapers run along the full length of the four internal passageways, feeding into a double tank running across the bottom of the shed. Internally, the tank is 41m long and 8.5m wide with a spine wall running down the centre to support 4.4m wide slats. The tanks also run underneath the central feed passage, with a suspended passageway in place. The new shed provides 820m3 of slurry storage while there is also additional storage in other tanks in the yard.

Dividers

As there are a number of different groups within the shed (dry cows, in-calf heifers and beef stock) one feature that the Howards find very useful are pen dividers which make movement of stock around the shed much more streamlined.

Every second span of the shed, along both walls, is fitted with a high-pressure water point to allow ease of cleaning. These pipes run along the top of the walls but have been kept independent from the drinkers in the shed. A valve is in place outside the shed to allow water supply to these points to be turned off and the pipes drained to prevent freezing.

One issue that farmers have had with tip-over drinkers is the pipe getting pulled when they are tipped over. One small adaptation was to put a hook on the wall which holds the pipe in place.

It is very easy to see that both Gerard and Emer take great pride in their farm. Their mentality is to be commended. Everything has its place around the yard and they put in the work to keep it pristine. Not only does it make management easier but it provides a safe work environment which helps to reduce labour.

“We love what we are doing, it’s a great way of life and if you enjoy your work then you don’t really work a day,” said Gerard.

Emer and Gerard Howard from Carrigabrick, Fermoy, Co Cork.

Cost

The total cost of the project came to approximately €450,000 including VAT. Emer and Gerard are in a partnership so were able to avail of a 40% grant of a higher ceiling of €160,000 through TAMS (Targeted Agricultural Modernisation Scheme) which meant a grant aid of €64,000.

Once the grant element and VAT element are refunded, the net cost will work out at approximately €350,000, or €1,750/head if accommodating 200 cattle.

Having one central contractor for the project made life much easier throughout the project, according to both Gerard and Emer. “The workmanship of all the lads was second to none,” said Gerard. “All the people who worked here knew what they were doing and it made the whole project easier.”

Mulcahy Steel fabricated and supplied the shed while also completing all sitework and concrete work for the project. They also fitted the barriers and gates, supplied by Condon Engineering. Aidan Kelly of Agri-Design and Planning Services completed the drawings for the shed and the planning permission application.

Plumbing was carried out by Thomas and James Kearney, while David Barry and David O’Mahoney completed the electrical work for the shed.

Joe Collins of FDC accountants set up the partnership and completed the grant application. They also secured the finance for the project from Bank of Ireland. The Dairymaster scrapers were supplied and fitted by Richard Quane Dairy Services.

A new 198-cubicle shed has recently been installed on the farm of Gerard and Emer Howard from just outside of Fermoy in Co Cork. The farm has steadily increased numbers since quotas went, moving from 80 to 140 cows.

However, with limited winter accommodation on the farm it meant that other sheds had to be rented away from the home yard. This meant a lot of time was spent on the road feeding cattle. The new shed was seen as key to reducing workload for the farm, with all stock now located in the one central yard.

“We were renting sheds away from the yard last year and some of them were within 5km of the farm but others were up on 20km away which could take three hours to feed,” Gerard explained.

The farm brings all youngstock through to slaughter, while also buying in additional calves to finish too. Therefore at any one time the shed could be accommodating cows, replacement heifers and cattle for finishing.

“We are happy at the numbers we have now,” Emer explained, “If we went up more numbers then it would just mean that we would have to hire in more labour, which is not what we want.”

Gerard added: “I like the beef. It’s good to have it (the beef) in a year when the milk price is bad and it helps not to have all your eggs in one basket. We like having a variety. It adds to the bottom line at the end of the day and we can make a good income from them.”

The shed/ch>

The shed is 52.9m long and 38.4m wide with a feed passage running down through the centre of the shed. A 7.7m-wide central feed passage was decided on to ensure plenty of room to accommodate the diet feeder. The shed stands at 4.5m to the eaves, rising to 10.4m at the apex of the ridge cap. The roof has a 15° slope.

The shed is used to hold beef cattle as well as cows, and while all cows will be stocked at one cow/cubicle, for the beef stock higher stocking rates are used. The shed will generally be used to hold over 200 cattle at any one time.

Cattle are fed along one end of the shed to provide additional space. “About 220 can eat at the one time if we needed, with the extra feed space at either end,” according to Gerard. Total length of available feed face is approximately 136m, which if used to accommodate 200 cattle would mean space of 680mm/animal.

Inlet ventilation is provided through a combination of vented sheeting and a continuous opening running directly below the eaves. As the shed is over 24m wide then a continuous opening of 450mm is required in addition to the vented sheeting.

“We are happy with the movement of air throughout the shed, but you do need the opening,” according to Gerard.

Excluding the central feed passage, area within the shed is 8m2 per cow, at 200 cows.

Cubicles

A three-row cubicle design was chosen for each side of the shed. Crossover points, fitted with tip-over drinkers, are in place at either end of the row of cubicles. Cubicles along the wall measure 2.45m while the head-to-head cubicles are 2.27m long each. The back passage of the shed is 3m wide while the front passage, along the feed barrier, is 4.6m wide. The wide passage along the feed barrier is in a bid to reduce bullying of young or smaller cows.

“We went with the diagonal feed barriers as it means that we can feed bales of silage or zero-grazed grass without worrying about it being pulled into the passageways,” Gerard explained.

“We had originally costed to just have a straight bar in but we said when we were doing it that we would do it once and do it right.”

Two bays are dedicated to a calving area within the shed, with a 146m2 straw bedded area on either side of the feed passage. Each pen is fitted with a calving gate while the gates at the front of the calving pen have been designed so that cows can be given access to one or two spans of the feed barrier. This means that if there are two cows in the calving pen they will not be taking up potentially where 18 cows could feed.

Slurry

Dairymaster scrapers run along the full length of the four internal passageways, feeding into a double tank running across the bottom of the shed. Internally, the tank is 41m long and 8.5m wide with a spine wall running down the centre to support 4.4m wide slats. The tanks also run underneath the central feed passage, with a suspended passageway in place. The new shed provides 820m3 of slurry storage while there is also additional storage in other tanks in the yard.

Dividers

As there are a number of different groups within the shed (dry cows, in-calf heifers and beef stock) one feature that the Howards find very useful are pen dividers which make movement of stock around the shed much more streamlined.

Every second span of the shed, along both walls, is fitted with a high-pressure water point to allow ease of cleaning. These pipes run along the top of the walls but have been kept independent from the drinkers in the shed. A valve is in place outside the shed to allow water supply to these points to be turned off and the pipes drained to prevent freezing.

One issue that farmers have had with tip-over drinkers is the pipe getting pulled when they are tipped over. One small adaptation was to put a hook on the wall which holds the pipe in place.

It is very easy to see that both Gerard and Emer take great pride in their farm. Their mentality is to be commended. Everything has its place around the yard and they put in the work to keep it pristine. Not only does it make management easier but it provides a safe work environment which helps to reduce labour.

“We love what we are doing, it’s a great way of life and if you enjoy your work then you don’t really work a day,” said Gerard.

Emer and Gerard Howard from Carrigabrick, Fermoy, Co Cork.

Cost

The total cost of the project came to approximately €450,000 including VAT. Emer and Gerard are in a partnership so were able to avail of a 40% grant of a higher ceiling of €160,000 through TAMS (Targeted Agricultural Modernisation Scheme) which meant a grant aid of €64,000.

Once the grant element and VAT element are refunded, the net cost will work out at approximately €350,000, or €1,750/head if accommodating 200 cattle.

Having one central contractor for the project made life much easier throughout the project, according to both Gerard and Emer. “The workmanship of all the lads was second to none,” said Gerard. “All the people who worked here knew what they were doing and it made the whole project easier.”

Mulcahy Steel fabricated and supplied the shed while also completing all sitework and concrete work for the project. They also fitted the barriers and gates, supplied by Condon Engineering. Aidan Kelly of Agri-Design and Planning Services completed the drawings for the shed and the planning permission application.

Plumbing was carried out by Thomas and James Kearney, while David Barry and David O’Mahoney completed the electrical work for the shed.

Joe Collins of FDC accountants set up the partnership and completed the grant application. They also secured the finance for the project from Bank of Ireland. The Dairymaster scrapers were supplied and fitted by Richard Quane Dairy Services.

SHARING OPTIONS