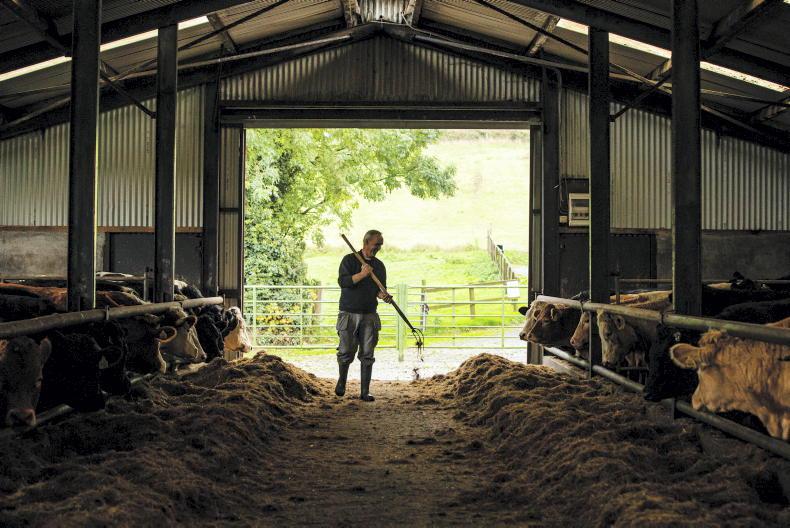

Jonathan Chapman is an award-winning suckler farmer who farms in Cornwall in the south of England.

He worked as a vet for 15 years and came home to farm full-time five years ago.

He has a clear vision of what he wants a suckler cow to deliver – and if she doesn’t she doesn’t stay on the farm.

Jonathan also has a very clear breeding plan, sticking to tight timelines and dates along with a major focus on grassland management and soil health on his farm.

He runs the Atlantic Abereeden Angus herd, but only the top animals are sold for breeding with the remainder finished on farm.

During his presentation he commented: “We have a commercial herd that happens to be pedigree.

"I want to breed cattle that genuinely work for farmers, for the environment and for the consumer. We are finding that we can put 90kgs of carbon into the soil.

“Data underpins everything that we do.”

Jonathan explained that the herd has a current culling rate of 25%.

“In my opinion the ruthless culling drives herd performance, if the cow doesn’t fit the system she goes.”

Cows calve indoors in spring in a tight seven-week window.

In 2025, Jonathan had a 101% calving rate with 75% of the cows calving within three weeks.

All heifers calve at two years old on the farm.

The farm is driven by informed decision-making made by analysing data recorded on the farm.

Jonathan has even gone as far as designing his own app for recording key data at calving time and weighing time.

Things like teat score, foot scores, locomotion and docility are all recorded on cows via the app on a regular basis.

“I wanted something really simple so went about designing what would work for me. It was actually a really simple process,” he said.

The 2025 200-day weights of calves being weaned are up at 60% of the weight of the cow and this is also being achieved at a relatively high stocking rate.

The UK Aberdeen Angus society has recorded a 15% increase in cow weight over the last 10 years, which means Aberdeen Angus cows are now 100kg heavier.

Scott Donaldson speaking at the British Cattle Breeders Conference in the UK this week

Jonathan is conscious of this and doesn’t want his cows to increase in size, so his breeding choices are being made around this. Docile cattle are also key to the system.

“It’s a family farm with my children regular helping out with cattle so that’s very important to us.”

A veterinary background means Jonathan is focused on maintaining a healthy herd. All cows are vaccinated for BVD with all animals vaccinated against IBR and bluetongue.

Faecal sampling is carried out on a regular basis during the grazing season to determine whether dosing is required or not.

Jonathan also monitors kill sheets for any signs of fluke with animals treated accordingly.

The farm doesn’t use fly treatments or ivermectin-based products to dry and preserve dock beetles.

Consumer driven good beef index

Jonathan places a huge emphasis on meeting consumer demand and his farm is one of the founding members of the GoodBeef Index, which verifies the production, eating-quality and environmental attributes of the beef produced on the farm.

Scanning the fat marbling of cattle on the farm happens on a regular basis with US-manufactured technology.

The index scores individual animals out of a maximum score of 120.

If an animal scores between 100-110, it achieves the prime status which points to pure suckler beef in the top 2-3% for eating quality and farmed in an environmentally beneficial way.

The family have opened a farm shop and some animals are sold through that on an annual basis.

“The farm shop help us to connect with our consumers and get a better understanding of what they need.

“We also run some farm tours for our customers so they understand what our production system is like.

“Grass-fed beef has high omega 3 levels and we need to do more to communicate that to consumers.” Jonathan explained.

Jonathan Chapman, Holsworthy, Cornwall, United Kingdom.Farm size: 350 Ha (240 Ha owned and 110 Ha rented) 300 fields.Land type: mixed (heavy clay soil and steep hills).System: suckler to beef, selling best cattle for breeding and remainder finished on farm.Type: 210 Aberdeen Angus suckler cows and 450 followers.Carcase weight: 330kg (R4L).Fit the cow to the system and keep the system really simple. Easy calving and genetics that thirve off forage.Tight calving season-driven high fertility.Grass first system, as much as possible of forage, 90-95% finished off forage with a small amount of barley.Genetics, grazing and eating quality all linked together to form unique selling point.

Concern for future of UK suckler cow

The annual British Cattle Breeders Conference tok place last week in Telford with a full day’s line-up of speakers on all things beef cattle on Tuesday. One of the morning sessions heard from a number of speakers including a retailer, a processor and a livestock auctioneer.

Like the Irish suckler herd the UK herd has some real challenges in terms of maintaining numbers and encouraging the next generation of farmers into suckler systems.

Worryingly, while a huge amount of work has been completed for integrated supply chains on the dairy beef side of the supply chain, very little work appears to have taken place on the suckler side.

A number of questions from the audience pointed to genuine concern around the future of the UK suckler cow.

There were a number of views from the audience that there wasn’t enough being done for suckler farmers and that some injection of confidence was needed in the sector to stop the terminal decline in suckler numbers.

A number of members of the audience thought that suckler systems integrated with tillage systems offers the best chance of suckler systems surviving through regenerative farming practices.

There was a debate around whose job that was. Is it a processors job, a retailer’s job or someone else’s job to come up with a plan?

Sarah Haire, head of Agriculture with Dunbia commented on suckler beef and the challenges that lie within systems “The challenge that we have with the suckler herd is consistency. Beef is beef, it doesn’t matter whether it comes from the dairy herd or suckler herd.”

Speaking at the conference Henry Blain, head of livestock with Sainsburys spoke about the importance of security of supply and having a long-term plan for their beef supply chain. He outlined how Sainsbury’s, in conjunction with ABP, have worked together to develop their own system.

‘Gamechanger’ is the title for their integrated supply chain which includes a partnership with Oxbury bank offering finance for cattle.

Back in 2012, Sainsbury’s embarked on their first integrated supply chain with an aim of processing 3500 cattle which fed into a six-month trial at their butchery counters.

The integrated supply chain resulted in a reduction in customer complaints at their butchery counters and general good feedback on the eating quality of the beef that they purchased.

Market research points to more people purchasing more beef with repeat custom increased.

Sainsbury’s partnered with ABP along with a number of genetics companies to deliver the programme.

The data-led programme now feeds end-to-end supply chain data to all members who are working in the supply chain.

The programme has delivered for farmers. The number of animals being brought through the integrated programme has doubled in the last two years.

“Some of the genetics being used has reduced slaughter age by 65 days whilst improving carcase weights,” Blain explained.

This has resulted in a 25% reduction in the carbon footprint of the beef on their shelves. Sainsbury’s run a number of low-carbon lines of beef that are performing well at retail level.

Speaking on how the beef industry can move forward he said it was through better sharing of information, the supply chain working collaboratively and makng sure that everybody is going after the same things is the way forward.

Aberdeen Angus Association

More mart board information needed

Scott Donaldson is group director of livestock at H and H group in Carlisle and has 40 years of experience on the rostrum selling cattle across numerous marts in England and Scotland.

The lead in to his presentation explained how pedigree beef breeders invest considerable time and resources into recording performance data for the cattle that they produce.

This gives bull buyers the information they require to make informed decisions when purchasing their next stock bull.

He questioned the information that is available to the store cattle buyer when they are investing huge sums of money to fill sheds and he posed the question “do they need more data to make informed decisions at the ringside?”.

Donaldson outlined how pedigree sales have moved from a bull sale catalogue containing very basic pedigree information to BLUP figures to now EBVs which contain a myriad of figures on an animal’s performance and predicted performance.

Auction marts bring everything together, buyers, sellers, agents, families. This is why marts ae the best place.

The value in the ring is set fast. We need to make sure the right information is visible for the buyer.

“Buyers are choosing cattle quickly and haven’t time to process a lot of information.

“Specialist feeders purchase cattle, not on pedigree but rather on weights and performance attributes and what they can do for them.”

He added that this isn’t about doing away with the visual appraisal, type, locomotion and general bloom are also important in making decisions on purchasing but having extra data will help that decision making. “We need a communication upgrade, not a reinventing of the wheel,” Donaldson said.

“If it can’t be understood in 10 seconds it wont reliably change the bidding behaviour,” he added.

Donaldson outlined an example of what he though might work as part of this changeover to more data being displayed on boards including a predicted grade.

“Data is already there, it’s a simple upgrading of what we display for purchasers,” Donaldson said.

His thoughts are that once buyers use it and sellers see this being used this will bring about the change.

Completing the data circle means farmers have the data that they can use to make informed decisions.

Kicking back on some of the factory and supermarket sentiment at the top table panel disscussion Donaldson said “Out of spec isn’t out of fashion. We need to remember that we have a lot of different customers for different types of cattle.”

There was a general consensus at the top table that the current grading system isn’t working for what today’s consumer wants and that eating quality needs to be part of that payment model in the future.

Click here to listen to the full interview.

Jonathan Chapman is an award-winning suckler farmer who farms in Cornwall in the south of England.

He worked as a vet for 15 years and came home to farm full-time five years ago.

He has a clear vision of what he wants a suckler cow to deliver – and if she doesn’t she doesn’t stay on the farm.

Jonathan also has a very clear breeding plan, sticking to tight timelines and dates along with a major focus on grassland management and soil health on his farm.

He runs the Atlantic Abereeden Angus herd, but only the top animals are sold for breeding with the remainder finished on farm.

During his presentation he commented: “We have a commercial herd that happens to be pedigree.

"I want to breed cattle that genuinely work for farmers, for the environment and for the consumer. We are finding that we can put 90kgs of carbon into the soil.

“Data underpins everything that we do.”

Jonathan explained that the herd has a current culling rate of 25%.

“In my opinion the ruthless culling drives herd performance, if the cow doesn’t fit the system she goes.”

Cows calve indoors in spring in a tight seven-week window.

In 2025, Jonathan had a 101% calving rate with 75% of the cows calving within three weeks.

All heifers calve at two years old on the farm.

The farm is driven by informed decision-making made by analysing data recorded on the farm.

Jonathan has even gone as far as designing his own app for recording key data at calving time and weighing time.

Things like teat score, foot scores, locomotion and docility are all recorded on cows via the app on a regular basis.

“I wanted something really simple so went about designing what would work for me. It was actually a really simple process,” he said.

The 2025 200-day weights of calves being weaned are up at 60% of the weight of the cow and this is also being achieved at a relatively high stocking rate.

The UK Aberdeen Angus society has recorded a 15% increase in cow weight over the last 10 years, which means Aberdeen Angus cows are now 100kg heavier.

Scott Donaldson speaking at the British Cattle Breeders Conference in the UK this week

Jonathan is conscious of this and doesn’t want his cows to increase in size, so his breeding choices are being made around this. Docile cattle are also key to the system.

“It’s a family farm with my children regular helping out with cattle so that’s very important to us.”

A veterinary background means Jonathan is focused on maintaining a healthy herd. All cows are vaccinated for BVD with all animals vaccinated against IBR and bluetongue.

Faecal sampling is carried out on a regular basis during the grazing season to determine whether dosing is required or not.

Jonathan also monitors kill sheets for any signs of fluke with animals treated accordingly.

The farm doesn’t use fly treatments or ivermectin-based products to dry and preserve dock beetles.

Consumer driven good beef index

Jonathan places a huge emphasis on meeting consumer demand and his farm is one of the founding members of the GoodBeef Index, which verifies the production, eating-quality and environmental attributes of the beef produced on the farm.

Scanning the fat marbling of cattle on the farm happens on a regular basis with US-manufactured technology.

The index scores individual animals out of a maximum score of 120.

If an animal scores between 100-110, it achieves the prime status which points to pure suckler beef in the top 2-3% for eating quality and farmed in an environmentally beneficial way.

The family have opened a farm shop and some animals are sold through that on an annual basis.

“The farm shop help us to connect with our consumers and get a better understanding of what they need.

“We also run some farm tours for our customers so they understand what our production system is like.

“Grass-fed beef has high omega 3 levels and we need to do more to communicate that to consumers.” Jonathan explained.

Jonathan Chapman, Holsworthy, Cornwall, United Kingdom.Farm size: 350 Ha (240 Ha owned and 110 Ha rented) 300 fields.Land type: mixed (heavy clay soil and steep hills).System: suckler to beef, selling best cattle for breeding and remainder finished on farm.Type: 210 Aberdeen Angus suckler cows and 450 followers.Carcase weight: 330kg (R4L).Fit the cow to the system and keep the system really simple. Easy calving and genetics that thirve off forage.Tight calving season-driven high fertility.Grass first system, as much as possible of forage, 90-95% finished off forage with a small amount of barley.Genetics, grazing and eating quality all linked together to form unique selling point.

Concern for future of UK suckler cow

The annual British Cattle Breeders Conference tok place last week in Telford with a full day’s line-up of speakers on all things beef cattle on Tuesday. One of the morning sessions heard from a number of speakers including a retailer, a processor and a livestock auctioneer.

Like the Irish suckler herd the UK herd has some real challenges in terms of maintaining numbers and encouraging the next generation of farmers into suckler systems.

Worryingly, while a huge amount of work has been completed for integrated supply chains on the dairy beef side of the supply chain, very little work appears to have taken place on the suckler side.

A number of questions from the audience pointed to genuine concern around the future of the UK suckler cow.

There were a number of views from the audience that there wasn’t enough being done for suckler farmers and that some injection of confidence was needed in the sector to stop the terminal decline in suckler numbers.

A number of members of the audience thought that suckler systems integrated with tillage systems offers the best chance of suckler systems surviving through regenerative farming practices.

There was a debate around whose job that was. Is it a processors job, a retailer’s job or someone else’s job to come up with a plan?

Sarah Haire, head of Agriculture with Dunbia commented on suckler beef and the challenges that lie within systems “The challenge that we have with the suckler herd is consistency. Beef is beef, it doesn’t matter whether it comes from the dairy herd or suckler herd.”

Speaking at the conference Henry Blain, head of livestock with Sainsburys spoke about the importance of security of supply and having a long-term plan for their beef supply chain. He outlined how Sainsbury’s, in conjunction with ABP, have worked together to develop their own system.

‘Gamechanger’ is the title for their integrated supply chain which includes a partnership with Oxbury bank offering finance for cattle.

Back in 2012, Sainsbury’s embarked on their first integrated supply chain with an aim of processing 3500 cattle which fed into a six-month trial at their butchery counters.

The integrated supply chain resulted in a reduction in customer complaints at their butchery counters and general good feedback on the eating quality of the beef that they purchased.

Market research points to more people purchasing more beef with repeat custom increased.

Sainsbury’s partnered with ABP along with a number of genetics companies to deliver the programme.

The data-led programme now feeds end-to-end supply chain data to all members who are working in the supply chain.

The programme has delivered for farmers. The number of animals being brought through the integrated programme has doubled in the last two years.

“Some of the genetics being used has reduced slaughter age by 65 days whilst improving carcase weights,” Blain explained.

This has resulted in a 25% reduction in the carbon footprint of the beef on their shelves. Sainsbury’s run a number of low-carbon lines of beef that are performing well at retail level.

Speaking on how the beef industry can move forward he said it was through better sharing of information, the supply chain working collaboratively and makng sure that everybody is going after the same things is the way forward.

Aberdeen Angus Association

More mart board information needed

Scott Donaldson is group director of livestock at H and H group in Carlisle and has 40 years of experience on the rostrum selling cattle across numerous marts in England and Scotland.

The lead in to his presentation explained how pedigree beef breeders invest considerable time and resources into recording performance data for the cattle that they produce.

This gives bull buyers the information they require to make informed decisions when purchasing their next stock bull.

He questioned the information that is available to the store cattle buyer when they are investing huge sums of money to fill sheds and he posed the question “do they need more data to make informed decisions at the ringside?”.

Donaldson outlined how pedigree sales have moved from a bull sale catalogue containing very basic pedigree information to BLUP figures to now EBVs which contain a myriad of figures on an animal’s performance and predicted performance.

Auction marts bring everything together, buyers, sellers, agents, families. This is why marts ae the best place.

The value in the ring is set fast. We need to make sure the right information is visible for the buyer.

“Buyers are choosing cattle quickly and haven’t time to process a lot of information.

“Specialist feeders purchase cattle, not on pedigree but rather on weights and performance attributes and what they can do for them.”

He added that this isn’t about doing away with the visual appraisal, type, locomotion and general bloom are also important in making decisions on purchasing but having extra data will help that decision making. “We need a communication upgrade, not a reinventing of the wheel,” Donaldson said.

“If it can’t be understood in 10 seconds it wont reliably change the bidding behaviour,” he added.

Donaldson outlined an example of what he though might work as part of this changeover to more data being displayed on boards including a predicted grade.

“Data is already there, it’s a simple upgrading of what we display for purchasers,” Donaldson said.

His thoughts are that once buyers use it and sellers see this being used this will bring about the change.

Completing the data circle means farmers have the data that they can use to make informed decisions.

Kicking back on some of the factory and supermarket sentiment at the top table panel disscussion Donaldson said “Out of spec isn’t out of fashion. We need to remember that we have a lot of different customers for different types of cattle.”

There was a general consensus at the top table that the current grading system isn’t working for what today’s consumer wants and that eating quality needs to be part of that payment model in the future.

Click here to listen to the full interview.

SHARING OPTIONS