Mayo-based machinery manufacturer McHale is set to launch a new Fusion at this year’s Ploughing. Up to now, McHale was offering three models in the Fusion range, the Fusion 3 entry level machine, the Fusion 3 Plus with film binding technology and the Variable Chamber Fusion Vario.

At this year’s National Ploughing Championships, the west of Ireland firm is set to add the new Fusion 3 Pro to the range. This machine will slot in between the Fusion 3 and the McHale Fusion 3 Plus, giving the operator access to more options, such as net and density adjustment, bale moisture recording, bale weighing system and cameras. The Fusion 3 Pro will use net to bind the bale in the chamber.

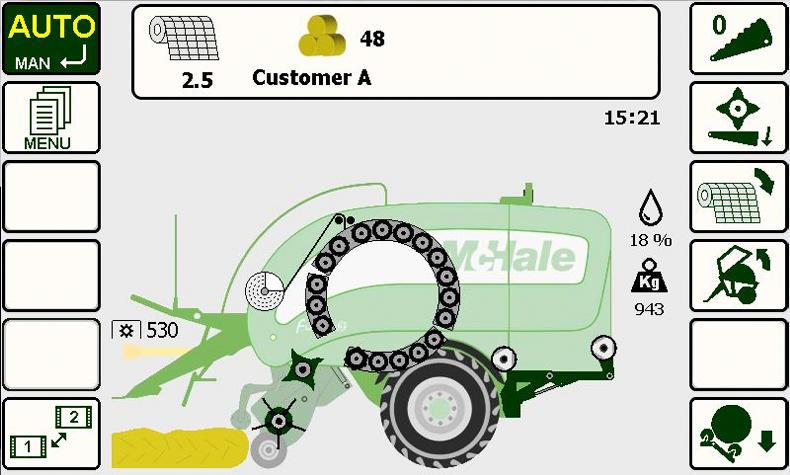

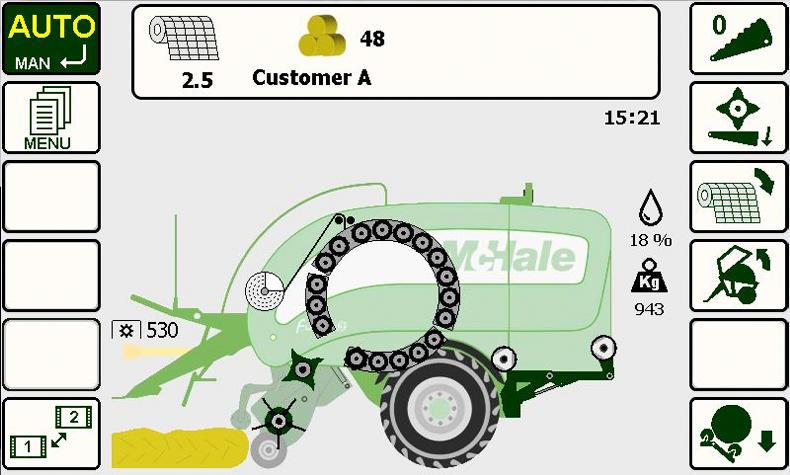

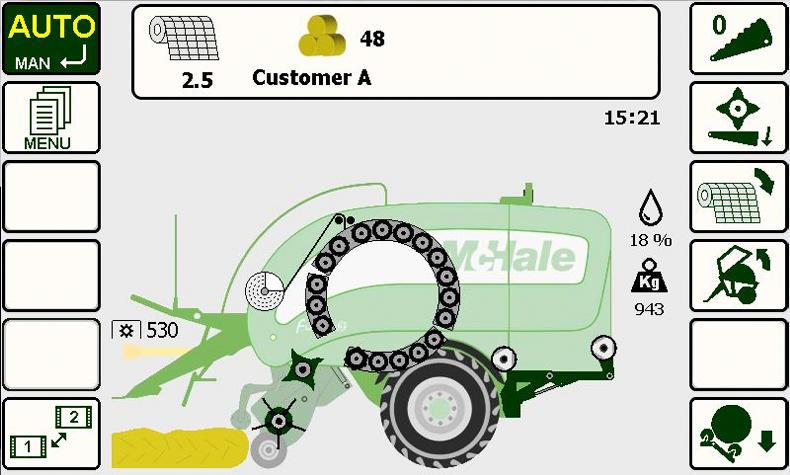

The operator’s in cab link to the machine is the iTouch control console with its 7” touchscreen monitor.

Like the existing Fusions, the Fusion 3 Pro shares the McHale patented bale transfer. McHale exclusively informed the Irish Farmers Journal that the wrapping speed on the new Fusion 3 Pro has been increased by 20%, allowing the machine to apply four layers in approximately 18 seconds or six layers in approximately 24 seconds. This means baler output is not restricted by the wrapping speed.

iTouch control console

The operator’s in-cab link is the iTouch control console with its 7in touchscreen monitor. The McHale Fusion 3 Pro comes fitted with one camera as standard to monitor the transfer and wrapping operation at the rear of the machine. The camera image automatically displays on the 7in monitor in the tractor cab at key points throughout the cycle, such as when the bale is being transferred to the wrapping table, at the beginning of the wrapping cycle and when the bale is about to be tipped. The iTouch control console has a second camera input if required.

From the console, the operator can adjust bale density and the number of layers of net from the cab.

New features

The new Fusion 3 Pro has a number of new features not available on the standard Fusion 3. The Pro model has an automatic drop floor reset as standard. If a blockage occurs, the operator can press a button on the iTouch to lower the floor. After the PTO is re-engaged and the blockage is fed through, the drop floor will automatically rise and the knives will reset to their original position.

An automatic knife drop feature can also be accessed from the iTouch control console in the cab. This allows the operator to chop the grass until the bale is 95% complete, at which point the machine will automatically drop out the knives. Depending on the feeding method, this can improve fodder distribution, keeping the bale neater when the net is removed.

Meanwhile, an end of wrapping roll function allows the bale to be rolled after wrapping has finished, to ensure the plastic is bound tightly to the bale.

The Pro model has an automatic drop floor reset as standard.

An output for controlling a crop additive applicator is also available on the iTouch control console. Once the operator has the PTO running, it will engage an aftermarket crop additive applicator. During the application of the net and transfer of the bale, the applicator will automatically switch off in order to avoid the wastage of additive. An optional headland management kit is also available, to detect when the pickup is raised at headlands and switch off the applicator to avoid further wastage of additive.

A “reset total reminder” will prompt the operator to reset the customer total when changing between fields. A USB export feature allows for bale totals and individual customer details to be exported to a USB.

Optional Extras

The Fusion Pro can be ordered with a camless pickup reel with six tine bars and a double crop roller. A selectable knife bank is also available. It comes as two banks, with 0, 12, 13 or 25 knife chopping options. A net loading device is also available.

It can also be equipped with additional features, including a bale weighing and moisture recording system. If the machine is fitted with the optional bale weighing system, the reading will be displayed on the iTouch screen. The system will record the weight of each bale and the average bale weight for the job will be displayed in the customer profile section on the iTouch control console. If equipped with the moisture recording system, a figure will be displayed as an average moisture content reading of the bale. This average value is then accumulated in the on-screen customer profile.

An optional printer is also available to create a customised receipt, which includes information on customer details, number of bales, chopped or non-chopped bale details, wrapped or un-wrapped bale details, average moisture content and average bale weight.

Standard features

Like the Fusion 3 and the Fusion 3 Plus, standard features on the McHale Fusion 3 Pro will include a 2.1m pickup, 25-knife chopper unit, knife pressure and position display, drop-floor unblocking system, 18 roller bale chamber with heavy duty shafts, 50mm double-row chamber bearings, heavy duty chains and an automatic greasing and oiling system.

Straw blower

First entering the silage feeder and straw blower market in 2012 with the C460, McHale’s offering now extends to four models. This includes a new larger C490 model that the company will also be launching at this year’s Ploughing.

The new C490 will be the flagship model in the C4 silage range of silage feeders and straw blowers. This will be the first time Irish buyers will see the new model. McHale launched it onto the European market at SIMA back in February.

The new machine has a 6.85m3 loading volume. McHale claims that the machine can handle three 5ft round bales of forage. Overall design is similar to the existing range, however the 3m hydraulically driven chain and slat conveyer is split into two.

The machine has a twin-speed independent gearbox, which allows the operator to adjust the rpm from 280rpm for feeding silage or hay, up to 540rpm for distributing straw for bedding. The slats on the hydraulically-driven floor conveyor are mounted on an 11mm high-tensile chain. It has a 1.57m diameter flywheel with six blowing paddles and a belt-driven rotor, which means the system can be hydraulically engaged or disengaged. The feed rotor is equipped with 56 blades mounted on seven discs and runs independent to the flywheel.

The C490 has the C4 Expert Control Console. Its functions include floor movement, comb control, loading door control, rotor control, floor direction and speed. The chute is joystick-controlled, allowing the operator to adjust its height and direction.

The three stage chute can rotate 300°. McHale claims that the machine will discharge material up to 18 metres. The latest introduction to the C4 range means the series offering rises to four models, beginning with the mounted 2.2m3 C430.

Mayo-based machinery manufacturer McHale is set to launch a new Fusion at this year’s Ploughing. Up to now, McHale was offering three models in the Fusion range, the Fusion 3 entry level machine, the Fusion 3 Plus with film binding technology and the Variable Chamber Fusion Vario.

At this year’s National Ploughing Championships, the west of Ireland firm is set to add the new Fusion 3 Pro to the range. This machine will slot in between the Fusion 3 and the McHale Fusion 3 Plus, giving the operator access to more options, such as net and density adjustment, bale moisture recording, bale weighing system and cameras. The Fusion 3 Pro will use net to bind the bale in the chamber.

The operator’s in cab link to the machine is the iTouch control console with its 7” touchscreen monitor.

Like the existing Fusions, the Fusion 3 Pro shares the McHale patented bale transfer. McHale exclusively informed the Irish Farmers Journal that the wrapping speed on the new Fusion 3 Pro has been increased by 20%, allowing the machine to apply four layers in approximately 18 seconds or six layers in approximately 24 seconds. This means baler output is not restricted by the wrapping speed.

iTouch control console

The operator’s in-cab link is the iTouch control console with its 7in touchscreen monitor. The McHale Fusion 3 Pro comes fitted with one camera as standard to monitor the transfer and wrapping operation at the rear of the machine. The camera image automatically displays on the 7in monitor in the tractor cab at key points throughout the cycle, such as when the bale is being transferred to the wrapping table, at the beginning of the wrapping cycle and when the bale is about to be tipped. The iTouch control console has a second camera input if required.

From the console, the operator can adjust bale density and the number of layers of net from the cab.

New features

The new Fusion 3 Pro has a number of new features not available on the standard Fusion 3. The Pro model has an automatic drop floor reset as standard. If a blockage occurs, the operator can press a button on the iTouch to lower the floor. After the PTO is re-engaged and the blockage is fed through, the drop floor will automatically rise and the knives will reset to their original position.

An automatic knife drop feature can also be accessed from the iTouch control console in the cab. This allows the operator to chop the grass until the bale is 95% complete, at which point the machine will automatically drop out the knives. Depending on the feeding method, this can improve fodder distribution, keeping the bale neater when the net is removed.

Meanwhile, an end of wrapping roll function allows the bale to be rolled after wrapping has finished, to ensure the plastic is bound tightly to the bale.

The Pro model has an automatic drop floor reset as standard.

An output for controlling a crop additive applicator is also available on the iTouch control console. Once the operator has the PTO running, it will engage an aftermarket crop additive applicator. During the application of the net and transfer of the bale, the applicator will automatically switch off in order to avoid the wastage of additive. An optional headland management kit is also available, to detect when the pickup is raised at headlands and switch off the applicator to avoid further wastage of additive.

A “reset total reminder” will prompt the operator to reset the customer total when changing between fields. A USB export feature allows for bale totals and individual customer details to be exported to a USB.

Optional Extras

The Fusion Pro can be ordered with a camless pickup reel with six tine bars and a double crop roller. A selectable knife bank is also available. It comes as two banks, with 0, 12, 13 or 25 knife chopping options. A net loading device is also available.

It can also be equipped with additional features, including a bale weighing and moisture recording system. If the machine is fitted with the optional bale weighing system, the reading will be displayed on the iTouch screen. The system will record the weight of each bale and the average bale weight for the job will be displayed in the customer profile section on the iTouch control console. If equipped with the moisture recording system, a figure will be displayed as an average moisture content reading of the bale. This average value is then accumulated in the on-screen customer profile.

An optional printer is also available to create a customised receipt, which includes information on customer details, number of bales, chopped or non-chopped bale details, wrapped or un-wrapped bale details, average moisture content and average bale weight.

Standard features

Like the Fusion 3 and the Fusion 3 Plus, standard features on the McHale Fusion 3 Pro will include a 2.1m pickup, 25-knife chopper unit, knife pressure and position display, drop-floor unblocking system, 18 roller bale chamber with heavy duty shafts, 50mm double-row chamber bearings, heavy duty chains and an automatic greasing and oiling system.

Straw blower

First entering the silage feeder and straw blower market in 2012 with the C460, McHale’s offering now extends to four models. This includes a new larger C490 model that the company will also be launching at this year’s Ploughing.

The new C490 will be the flagship model in the C4 silage range of silage feeders and straw blowers. This will be the first time Irish buyers will see the new model. McHale launched it onto the European market at SIMA back in February.

The new machine has a 6.85m3 loading volume. McHale claims that the machine can handle three 5ft round bales of forage. Overall design is similar to the existing range, however the 3m hydraulically driven chain and slat conveyer is split into two.

The machine has a twin-speed independent gearbox, which allows the operator to adjust the rpm from 280rpm for feeding silage or hay, up to 540rpm for distributing straw for bedding. The slats on the hydraulically-driven floor conveyor are mounted on an 11mm high-tensile chain. It has a 1.57m diameter flywheel with six blowing paddles and a belt-driven rotor, which means the system can be hydraulically engaged or disengaged. The feed rotor is equipped with 56 blades mounted on seven discs and runs independent to the flywheel.

The C490 has the C4 Expert Control Console. Its functions include floor movement, comb control, loading door control, rotor control, floor direction and speed. The chute is joystick-controlled, allowing the operator to adjust its height and direction.

The three stage chute can rotate 300°. McHale claims that the machine will discharge material up to 18 metres. The latest introduction to the C4 range means the series offering rises to four models, beginning with the mounted 2.2m3 C430.

SHARING OPTIONS