They say money focuses the mind. With fertiliser prices continuing to surge to alarming and unprecedented levels, our industry will have to closely consider all of its options and alternative sources.

One application method which is gaining popularity in New Zealand and Australia is the Tow and Fert system. Built in New Zealand, the Tow and Fert machine could be called a hybrid between a fertiliser spreader and a sprayer.

Through a combination of machine use and a systems approach, we visited a Tipperary dairy farmer who claims to have reduced his fertiliser usage by 41% without compromising on grass growth.

The farm

Robert Coburn from Carrigahorig in north Tipperary is milking 365 cows, stocked at 3.25 LU/ha on the grazing platform.

We visited as he was applying a mix of milk, water and soil enhancer to some of his paddocks through his Tow and Fert Multi 1200.

With the move from sucklers and sheep to dairying in 2012 and increasing cow numbers each year, Robert felt that the trend towards applying high rates of artificial fertiliser wasn’t the most sustainable route for his farm.

After reading an article in the Irish Farmers Journal in late 2016, Robert came across the Tow and Fert. He purchased the Multi 1200, which arrived during the 2017 spreading season.

This was one of the first three units which were sold into Ireland.

Robert’s machine is the dual-boom version, which allows for a spray width of up to 20m.

The system

Robert explained: “The soil is a living organism, which needs to be fed and looked after. Soil health isn’t just about horsing out pallets of N, P and K. The biology such as earthworms, bacteria and the fungi play a vital role. I’m a firm believer in healthy soil, healthy cow.

“Over the past 10 years, we have been doing things like treating our slurry, finding some products more successful than others. I find this brings our slurry to life, which we apply at moderate rates.

“The Tow and Fert is built for foliar application of nitrogen fertilisers, which is more plant-available over granular fertiliser.

“On our farm, we have reduced our fertiliser usage (mostly N) by 41%, by applying the mix after the cows at a cover of 500kg to 700kg DM/ha. We also use the machine to feed the soil biology by spreading products such as glucose, milk and molasses mixed with trace elements and soil enhancers.

“The Tow and Fert system allows us to apply such products with urea all in one mix. This has allowed us to cut our fertiliser usage in the region of 30t per annum over the past three years,” he added.

Robert explained that the system is capable of mixing the half tonne of urea in around three minutes.

What is Tow and Fert?

Tow and Fert is designed and built by Metalform. Based in the North Island town of Dannevirke in New Zealand, the Tow and Fert concept was born in 2009. The company employs 100 people and has machines working across New Zealand, Australia, Ireland, the UK and the USA.

Today, its range is made up of five models. This starts with the ATV-pulled Multi 500 – a 500l and up to 10m (32ft) working width machine – right up to the contractor-spec trailed PTO-driven Multi 4000, which is a 4,000l model with up to a 24m (79ft) working width.

The machine is imported and distributed across Europe by Leslie Dwyer of APS Bioag in Co Kildare.

Built into the 1,200l tank is a hydraulically powered belt-driven agitation system which features a patented housed impeller.

The concept

The Tow and Fert machines are primarily designed as liquid foliar spray machines. They have the ability to dissolve any nitrogen-based fertiliser, but primarily urea, into a plant-available liquid solution.

The machine also has the ability to mix, suspend and apply micro-fine particulate and biological fertilisers while suspended in liquid. This includes very finely ground limestone (less than 15 microns – ground lime is approximately 2,000 microns).

It can also be used to apply small seeds such as chicory or clover.

The booms are quite wide in transport position on the road, they sit out a few inches either side of the tractor’s rear tyres.

How does it work?

The Multi 1200 is a three-point-linkage-mounted machine. With a 1,200l tank, the Multi 1200 is designed to dissolve half a tonne of urea in cold water or hold 1.2t of dry fine particle product in suspension.

Built into the 1,200l tank is a hydraulically powered belt-driven agitation system, which features a patented housed impeller, meaning the product will never settle out of suspension.

The unit self-fills by sucking in liquid such as fresh water from a tank. The water is sucked in through a patented in-house-designed stainless-steel trash pump before passing through a large inline filter and distributed into the tank.

Robert says the system is capable of mixing the half tonne of urea in around three minutes.

Nozzle selection is based on the desired application rate, ranging from a flow rate of 20l/min up to 70l/min.

Spraying

This model can be specified with either one or two booms. Robert’s machine is the dual-boom version, which allows for a spray width of up to 20m.

However, this depends on the nozzle used. The machine comes with three nozzles, all of which are stainless steel. Nozzle selection is based on the desired application rate, ranging from a flow rate of 20l/min up to 70l/min, with the larger only being used for suspended lime application.

To maintain the mix in suspension, the boom features a patented recirculation system. The company says that 90% of the mix in the booms is constantly being recirculated at any one time, with the remaining 10% being discharged.

The larger models can be engaged and disengaged via remote control, whereas the pump on this particular model is engaged by putting the spool valve into constant pumping.

Once it gets to 2 bar pressure, it will begin to spread the mix.

Meanwhile, by pulling a cord, the same spool valve in constant pumping is responsible for sucking in the liquid.

One other spool valve is required, which is used to extend or retract the booms. Because of the machine’s large working width, a guidance system is crucial to its efficient use. Robert purchased a Farm Navigator system when he bought the machine.

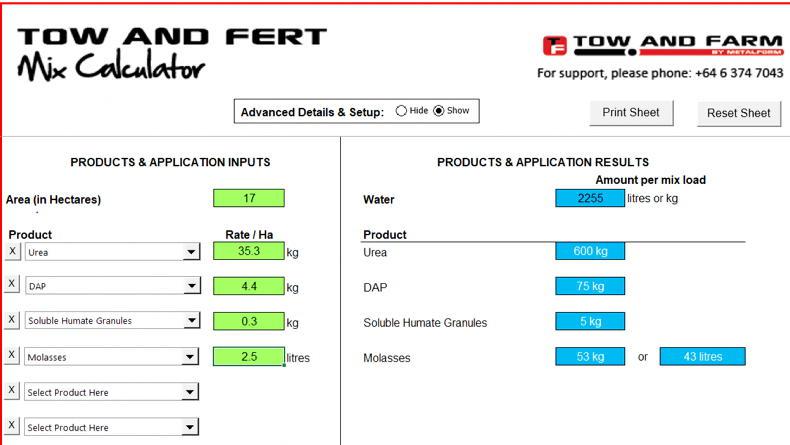

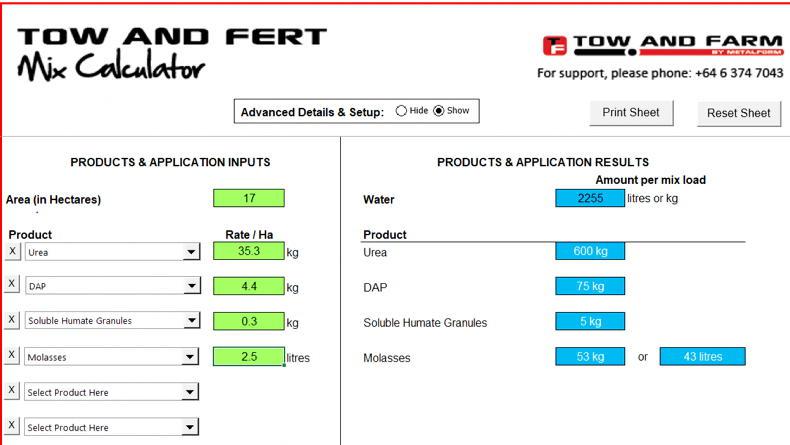

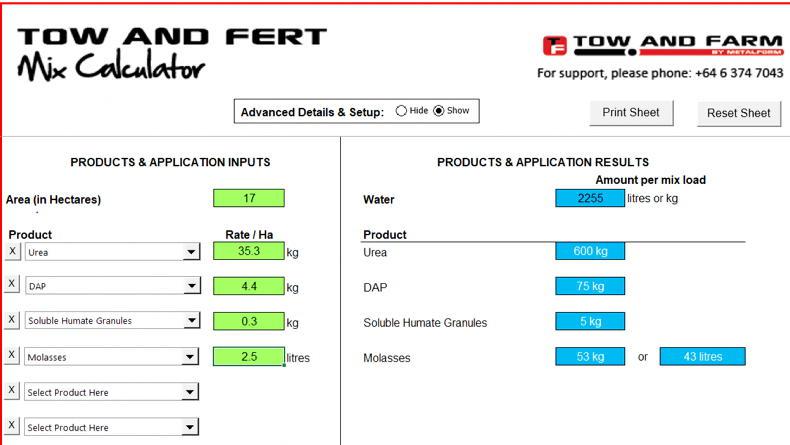

The mixes are calculated by using the on-board weighing scales and the Tow and Fert mix calculator. Interestingly, Robert has never carried out a tray test, claiming it is not necessary.

The mixes are calculated by using the machine's on-board weighing scales and by using the Tow and Fert mix calculator.

The water is sucked in through a patented in-house-designed stainless-steel trash pump before passing through a large inline filter and distributed into the tank.

Applications

“Traditionally, we would have followed the cows by spreading a bag (375kg) of granular urea on 10 acres. With the Tow and Fert, we cover 20 acres with the same bag (17.25 units/acre), except it’s applied in foliar form.

“When grass growth is slower early in the spring, we would apply the liquid mix to the paddocks seven to 10 days after grazing.

“When grass growth picks up and is at 80kg to 100kg/day, we would typically apply the mix on to the leaf at day four to six after grazing.

“We aim to spray the mix on to the grass at a cover of 500kg to 700kg DM/ha. The more leaf cover you have, the better the absorption will be.

“Meanwhile, to avoid any scorching, a trace element mix is incorporated into the solution.

“You also have to pick your day to spread. You can’t spread on a windy day and you need 12 hours of drying after application.

“You also need to avoid direct sunlight and temperatures above 20°C. Ideal conditions are often early in the morning or late at night when there is a dew out.

“We have also used the machine to sow seeds such as plantain and chicory. We soaked the mix in water 24 hours prior to application.

“Ahead of spraying, the field was grass harrowed, then the mix was sprayed on through a light liquid mix of urea followed by being rolled,” explained Robert.

By pulling the handle, it changes the pump from sucking to spreading.

“I’m very happy with the machine and how it has helped changed the way we farm. It has played a key role in part of a systems approach which has helped us vastly cut our fertiliser usage.

“The machine is well built, all from plastic and galvanised steel, so it is designed to handle corrosive products. All the fittings are cam locks which is a great job, they can be opened and or changed in the field without the need for tools.

“Its running costs have been €150 to date. The only down sides are that it is tight to put on to the tractor, as it’s positioned so close to the back end.

“The booms are also quite wide in transport position on the road. They sit out a few inches either side of the tractor’s rear tyres.

“Other than that, we’ve only had to change several wearing parts.

“All in all, it is a long-term investment, but, depending on your scale, it can quickly pay for itself. We are hoping to invest in one of the larger trailed models for the 2022 season,” explained Robert.

Build quality.Weigh cells.Use of plastic and galvanised components.Hard to put on/take off tractor.A dedicated on-off spreading switch would be a nice addition.Booms are wide in transport position.Model: Multi 1200.Working width: up to 20m.Application rate: 50-500 l/ha.Transport width: 2.4m.Weight: Dual boom: 850kg.Laden weight: max 2,500kg.Hydraulic requirement: 33l/min.Tractor requirement: 110hp+.Price: Multi 1200 single boom from €21,500 plus VAT.

They say money focuses the mind. With fertiliser prices continuing to surge to alarming and unprecedented levels, our industry will have to closely consider all of its options and alternative sources.

One application method which is gaining popularity in New Zealand and Australia is the Tow and Fert system. Built in New Zealand, the Tow and Fert machine could be called a hybrid between a fertiliser spreader and a sprayer.

Through a combination of machine use and a systems approach, we visited a Tipperary dairy farmer who claims to have reduced his fertiliser usage by 41% without compromising on grass growth.

The farm

Robert Coburn from Carrigahorig in north Tipperary is milking 365 cows, stocked at 3.25 LU/ha on the grazing platform.

We visited as he was applying a mix of milk, water and soil enhancer to some of his paddocks through his Tow and Fert Multi 1200.

With the move from sucklers and sheep to dairying in 2012 and increasing cow numbers each year, Robert felt that the trend towards applying high rates of artificial fertiliser wasn’t the most sustainable route for his farm.

After reading an article in the Irish Farmers Journal in late 2016, Robert came across the Tow and Fert. He purchased the Multi 1200, which arrived during the 2017 spreading season.

This was one of the first three units which were sold into Ireland.

Robert’s machine is the dual-boom version, which allows for a spray width of up to 20m.

The system

Robert explained: “The soil is a living organism, which needs to be fed and looked after. Soil health isn’t just about horsing out pallets of N, P and K. The biology such as earthworms, bacteria and the fungi play a vital role. I’m a firm believer in healthy soil, healthy cow.

“Over the past 10 years, we have been doing things like treating our slurry, finding some products more successful than others. I find this brings our slurry to life, which we apply at moderate rates.

“The Tow and Fert is built for foliar application of nitrogen fertilisers, which is more plant-available over granular fertiliser.

“On our farm, we have reduced our fertiliser usage (mostly N) by 41%, by applying the mix after the cows at a cover of 500kg to 700kg DM/ha. We also use the machine to feed the soil biology by spreading products such as glucose, milk and molasses mixed with trace elements and soil enhancers.

“The Tow and Fert system allows us to apply such products with urea all in one mix. This has allowed us to cut our fertiliser usage in the region of 30t per annum over the past three years,” he added.

Robert explained that the system is capable of mixing the half tonne of urea in around three minutes.

What is Tow and Fert?

Tow and Fert is designed and built by Metalform. Based in the North Island town of Dannevirke in New Zealand, the Tow and Fert concept was born in 2009. The company employs 100 people and has machines working across New Zealand, Australia, Ireland, the UK and the USA.

Today, its range is made up of five models. This starts with the ATV-pulled Multi 500 – a 500l and up to 10m (32ft) working width machine – right up to the contractor-spec trailed PTO-driven Multi 4000, which is a 4,000l model with up to a 24m (79ft) working width.

The machine is imported and distributed across Europe by Leslie Dwyer of APS Bioag in Co Kildare.

Built into the 1,200l tank is a hydraulically powered belt-driven agitation system which features a patented housed impeller.

The concept

The Tow and Fert machines are primarily designed as liquid foliar spray machines. They have the ability to dissolve any nitrogen-based fertiliser, but primarily urea, into a plant-available liquid solution.

The machine also has the ability to mix, suspend and apply micro-fine particulate and biological fertilisers while suspended in liquid. This includes very finely ground limestone (less than 15 microns – ground lime is approximately 2,000 microns).

It can also be used to apply small seeds such as chicory or clover.

The booms are quite wide in transport position on the road, they sit out a few inches either side of the tractor’s rear tyres.

How does it work?

The Multi 1200 is a three-point-linkage-mounted machine. With a 1,200l tank, the Multi 1200 is designed to dissolve half a tonne of urea in cold water or hold 1.2t of dry fine particle product in suspension.

Built into the 1,200l tank is a hydraulically powered belt-driven agitation system, which features a patented housed impeller, meaning the product will never settle out of suspension.

The unit self-fills by sucking in liquid such as fresh water from a tank. The water is sucked in through a patented in-house-designed stainless-steel trash pump before passing through a large inline filter and distributed into the tank.

Robert says the system is capable of mixing the half tonne of urea in around three minutes.

Nozzle selection is based on the desired application rate, ranging from a flow rate of 20l/min up to 70l/min.

Spraying

This model can be specified with either one or two booms. Robert’s machine is the dual-boom version, which allows for a spray width of up to 20m.

However, this depends on the nozzle used. The machine comes with three nozzles, all of which are stainless steel. Nozzle selection is based on the desired application rate, ranging from a flow rate of 20l/min up to 70l/min, with the larger only being used for suspended lime application.

To maintain the mix in suspension, the boom features a patented recirculation system. The company says that 90% of the mix in the booms is constantly being recirculated at any one time, with the remaining 10% being discharged.

The larger models can be engaged and disengaged via remote control, whereas the pump on this particular model is engaged by putting the spool valve into constant pumping.

Once it gets to 2 bar pressure, it will begin to spread the mix.

Meanwhile, by pulling a cord, the same spool valve in constant pumping is responsible for sucking in the liquid.

One other spool valve is required, which is used to extend or retract the booms. Because of the machine’s large working width, a guidance system is crucial to its efficient use. Robert purchased a Farm Navigator system when he bought the machine.

The mixes are calculated by using the on-board weighing scales and the Tow and Fert mix calculator. Interestingly, Robert has never carried out a tray test, claiming it is not necessary.

The mixes are calculated by using the machine's on-board weighing scales and by using the Tow and Fert mix calculator.

The water is sucked in through a patented in-house-designed stainless-steel trash pump before passing through a large inline filter and distributed into the tank.

Applications

“Traditionally, we would have followed the cows by spreading a bag (375kg) of granular urea on 10 acres. With the Tow and Fert, we cover 20 acres with the same bag (17.25 units/acre), except it’s applied in foliar form.

“When grass growth is slower early in the spring, we would apply the liquid mix to the paddocks seven to 10 days after grazing.

“When grass growth picks up and is at 80kg to 100kg/day, we would typically apply the mix on to the leaf at day four to six after grazing.

“We aim to spray the mix on to the grass at a cover of 500kg to 700kg DM/ha. The more leaf cover you have, the better the absorption will be.

“Meanwhile, to avoid any scorching, a trace element mix is incorporated into the solution.

“You also have to pick your day to spread. You can’t spread on a windy day and you need 12 hours of drying after application.

“You also need to avoid direct sunlight and temperatures above 20°C. Ideal conditions are often early in the morning or late at night when there is a dew out.

“We have also used the machine to sow seeds such as plantain and chicory. We soaked the mix in water 24 hours prior to application.

“Ahead of spraying, the field was grass harrowed, then the mix was sprayed on through a light liquid mix of urea followed by being rolled,” explained Robert.

By pulling the handle, it changes the pump from sucking to spreading.

“I’m very happy with the machine and how it has helped changed the way we farm. It has played a key role in part of a systems approach which has helped us vastly cut our fertiliser usage.

“The machine is well built, all from plastic and galvanised steel, so it is designed to handle corrosive products. All the fittings are cam locks which is a great job, they can be opened and or changed in the field without the need for tools.

“Its running costs have been €150 to date. The only down sides are that it is tight to put on to the tractor, as it’s positioned so close to the back end.

“The booms are also quite wide in transport position on the road. They sit out a few inches either side of the tractor’s rear tyres.

“Other than that, we’ve only had to change several wearing parts.

“All in all, it is a long-term investment, but, depending on your scale, it can quickly pay for itself. We are hoping to invest in one of the larger trailed models for the 2022 season,” explained Robert.

Build quality.Weigh cells.Use of plastic and galvanised components.Hard to put on/take off tractor.A dedicated on-off spreading switch would be a nice addition.Booms are wide in transport position.Model: Multi 1200.Working width: up to 20m.Application rate: 50-500 l/ha.Transport width: 2.4m.Weight: Dual boom: 850kg.Laden weight: max 2,500kg.Hydraulic requirement: 33l/min.Tractor requirement: 110hp+.Price: Multi 1200 single boom from €21,500 plus VAT.

SHARING OPTIONS