1 Will I make a profit?

Dairy calf-to-beef systems are relatively inexpensive to invest in initially but can have high costs per head up to slaughter. Cashflow also needs to be considered as there may be no sales for a long period of time.

For dairy calf-to-beef systems to be profitable, the value of the carcase produced must cover:1. The cost of buying the calf

2. All production costs to slaughter

3. A net margin per head

Before purchasing calves, farmers should estimate production costs and carcase value of the system they are aiming for to ensure they will return a profit.

Table 1 below gives guideline costs (excluding labour) and carcase weights for the most common calf-to-beef systems (operated at a high level of efficiency).

The figures above can be used by beef farmers to estimate the value of calves for sale:

+ Carcase weight × Estimated beef selling price (€/kg)

– Minus total costs (€/head)

– Minus net margin required (€/head)

= Value of calf (€/head)

2 Do I have suitable housing?

Housing is often the limiting factor on how many calves can be purchased. Calves should be housed in properly designed calf sheds with the correct space allowance, adequate ventilation and in very hygienic conditions with enough bedding.

Space allowance

Calves may be kept in single pens or in groups.As a general guide, a total floor area of 2.3m2 per calf (includes feed passage) with a cubic air capacity of approximately 10m3 per calf should be provided. Ventilation

Ventilated housing that is free of draughts will reduce the environmental stresses on calves and adequate air changes resulting from good ventilation reduce the infection load on the calves.Air outlet areas should be a minimum of 0.05m2 per calf and situated at least 1.5m higher than the inlet. The inlet area should be four times (minimum two times) the outlet area per calf.As a general rule, there should be 5cm of ridge opening for every 3m of building width. Bedding/hygiene

Prior to the arrival of each batch of calves, the shed should be thoroughly cleaned and disinfected with a broad-spectrum disinfectant.Bedding needs to be kept clean and dry and pens should be set up to allow for ease of cleaning and manure removal.Work and hygiene routines should be worked out in advance to prevent young calves catching disease from older or sick calves.The milk preparation area should be clean, dry and adjacent to the housing to reduce the labour input required at feeding.3 Where will I source calves?

Buying healthy calves is critical to the profitability of the system. Purchased calves should be alert, have clear eyes, dry navels, no swelling of joints, no signs of scour or pneumonia, shiny coats and be the correct weight for their age.

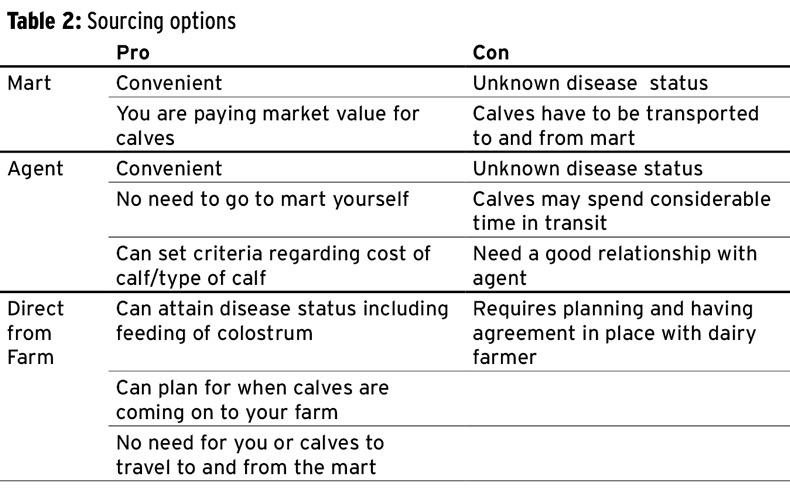

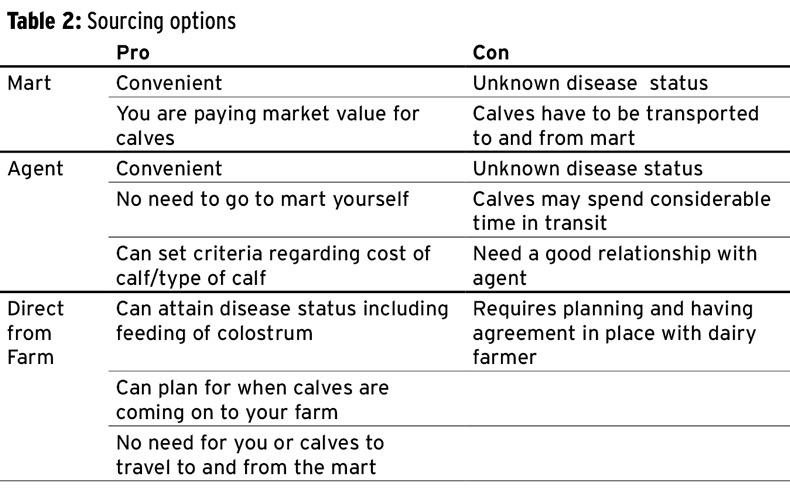

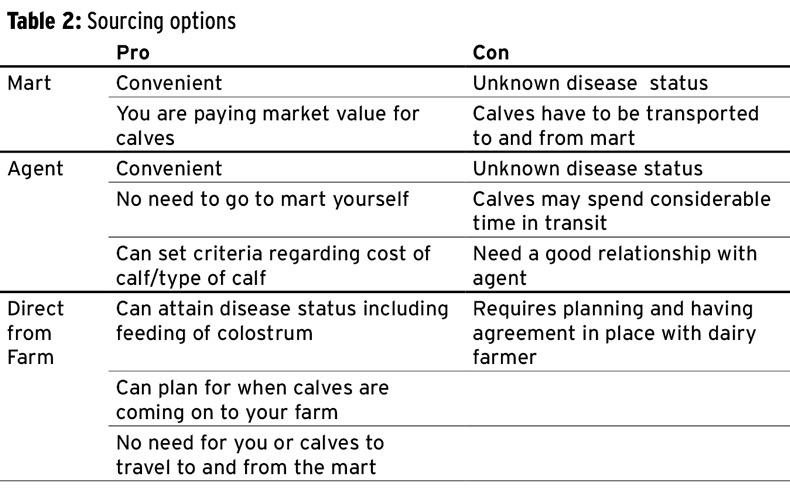

Calves ideally should be at least 14 to 21 days old and have good weight for age (45kg to 50kg at two weeks of age).Try to choose calves that have been fed sufficient colostrum.Select calves from as few sources as possible. Table 2 outlines the different sourcing options.

4 What will I feed the calves?

Pre-weaning nutrition affects growth rates, health and the ability to cope with cold stress. Young animals have the ability to convert feed into growth most efficiently during the first two months of life.

On arrival, allow calves two to three hours’ rest before feeding a good rehydration electrolyte as a first feed.Take rectal body temperatures. A high temperature is often the first sign of sickness. Take sick animals to a sick pen for examination and possible treatment by or upon advice of a veterinarian. Feeding programme

Feed calves 3l of calf milk replacer twice daily (at 12.5% solids) until they are at least three weeks of age.Supplement with good-quality starter concentrates and roughage in the form of good-quality chopped straw (not hay).Calves should have access to clean fresh water at all times.Calves should not be weaned until they are consuming at least 1kg/day of calf starter for three consecutive days.Wean calves gradually off milk replacer over a seven- to 10-day period.For a concentration of 12.5% solids, use 125g of milk powder and 875ml of water to make 1l of mixed milk.Protein levels in a calf milk replacer should be at least 23% to 26% and consist predominantly of milk proteins. Ensure that the water temperature is not greater than 39°C.

5 How can I keep the calf healthy?

Scours and pneumonia are the two most common causes of ill-health in calves and they should be checked daily for both.

Scours

Attention to hygiene is crucial to prevent scours.Treatment consists of pain and fever treatment combined with rehydration and proper nutrition.Isolate them from other calves to avoid cross-infection.Get electrolytes into them and DO NOT stop feeding them milk replacer.Pneumonia

The underlying causes of pneumonia in calves can be very complex.Insufficient colostrum, poorly designed houses, over-crowding, inadequate nutrition and stress all increase the possibility of an outbreak.Veterinary advice should be sought for a suitable vaccination programme which should include pasteurella and the respiratory viruses IBR (BHV-1), RSV and PI-3.Dehorning

Use a heated disbudding iron; it is the only method legally allowed in Ireland. Ideally, use a calf dehorning crate to minimise stress on the calf and for your own safety.Seek veterinary advice if sick calves do not respond quickly to treatment. DO NOT wean calves that show signs of ill-health. Read more

Focus: calves 2017

1 Will I make a profit?

Dairy calf-to-beef systems are relatively inexpensive to invest in initially but can have high costs per head up to slaughter. Cashflow also needs to be considered as there may be no sales for a long period of time.

For dairy calf-to-beef systems to be profitable, the value of the carcase produced must cover:1. The cost of buying the calf

2. All production costs to slaughter

3. A net margin per head

Before purchasing calves, farmers should estimate production costs and carcase value of the system they are aiming for to ensure they will return a profit.

Table 1 below gives guideline costs (excluding labour) and carcase weights for the most common calf-to-beef systems (operated at a high level of efficiency).

The figures above can be used by beef farmers to estimate the value of calves for sale:

+ Carcase weight × Estimated beef selling price (€/kg)

– Minus total costs (€/head)

– Minus net margin required (€/head)

= Value of calf (€/head)

2 Do I have suitable housing?

Housing is often the limiting factor on how many calves can be purchased. Calves should be housed in properly designed calf sheds with the correct space allowance, adequate ventilation and in very hygienic conditions with enough bedding.

Space allowance

Calves may be kept in single pens or in groups.As a general guide, a total floor area of 2.3m2 per calf (includes feed passage) with a cubic air capacity of approximately 10m3 per calf should be provided. Ventilation

Ventilated housing that is free of draughts will reduce the environmental stresses on calves and adequate air changes resulting from good ventilation reduce the infection load on the calves.Air outlet areas should be a minimum of 0.05m2 per calf and situated at least 1.5m higher than the inlet. The inlet area should be four times (minimum two times) the outlet area per calf.As a general rule, there should be 5cm of ridge opening for every 3m of building width. Bedding/hygiene

Prior to the arrival of each batch of calves, the shed should be thoroughly cleaned and disinfected with a broad-spectrum disinfectant.Bedding needs to be kept clean and dry and pens should be set up to allow for ease of cleaning and manure removal.Work and hygiene routines should be worked out in advance to prevent young calves catching disease from older or sick calves.The milk preparation area should be clean, dry and adjacent to the housing to reduce the labour input required at feeding.3 Where will I source calves?

Buying healthy calves is critical to the profitability of the system. Purchased calves should be alert, have clear eyes, dry navels, no swelling of joints, no signs of scour or pneumonia, shiny coats and be the correct weight for their age.

Calves ideally should be at least 14 to 21 days old and have good weight for age (45kg to 50kg at two weeks of age).Try to choose calves that have been fed sufficient colostrum.Select calves from as few sources as possible. Table 2 outlines the different sourcing options.

4 What will I feed the calves?

Pre-weaning nutrition affects growth rates, health and the ability to cope with cold stress. Young animals have the ability to convert feed into growth most efficiently during the first two months of life.

On arrival, allow calves two to three hours’ rest before feeding a good rehydration electrolyte as a first feed.Take rectal body temperatures. A high temperature is often the first sign of sickness. Take sick animals to a sick pen for examination and possible treatment by or upon advice of a veterinarian. Feeding programme

Feed calves 3l of calf milk replacer twice daily (at 12.5% solids) until they are at least three weeks of age.Supplement with good-quality starter concentrates and roughage in the form of good-quality chopped straw (not hay).Calves should have access to clean fresh water at all times.Calves should not be weaned until they are consuming at least 1kg/day of calf starter for three consecutive days.Wean calves gradually off milk replacer over a seven- to 10-day period.For a concentration of 12.5% solids, use 125g of milk powder and 875ml of water to make 1l of mixed milk.Protein levels in a calf milk replacer should be at least 23% to 26% and consist predominantly of milk proteins. Ensure that the water temperature is not greater than 39°C.

5 How can I keep the calf healthy?

Scours and pneumonia are the two most common causes of ill-health in calves and they should be checked daily for both.

Scours

Attention to hygiene is crucial to prevent scours.Treatment consists of pain and fever treatment combined with rehydration and proper nutrition.Isolate them from other calves to avoid cross-infection.Get electrolytes into them and DO NOT stop feeding them milk replacer.Pneumonia

The underlying causes of pneumonia in calves can be very complex.Insufficient colostrum, poorly designed houses, over-crowding, inadequate nutrition and stress all increase the possibility of an outbreak.Veterinary advice should be sought for a suitable vaccination programme which should include pasteurella and the respiratory viruses IBR (BHV-1), RSV and PI-3.Dehorning

Use a heated disbudding iron; it is the only method legally allowed in Ireland. Ideally, use a calf dehorning crate to minimise stress on the calf and for your own safety.Seek veterinary advice if sick calves do not respond quickly to treatment. DO NOT wean calves that show signs of ill-health. Read more

Focus: calves 2017

SHARING OPTIONS