Handling facilities are vital to the efficient running of any livestock enterprise. Good handling facilities reduce stress on the animal, prevent the risk of injury and also encourage regular handling of animals for management practices such as administering health treatments and weight recording.

There are a number of aspects that should be borne in mind when designing cattle handling facilities, irrespective of whether grant aid is being sought. The first of these is determining if planning permission is required.

Handling facilities are classified as a Class 8 structure under exempted development planning rules. Other structures in this class include roofless cubicles, open loose yards, self-feed silo or silage areas, feeding aprons, assembly yards, milking parlours or structures for the making or storage of silage. These structures must have an aggregate gross floor space that does not exceed 200m2 and also provide for effluent storage, where required.

Where the structure is cleaned after each use, there will generally not be any need for effluent/slurry storage. If storage facilities are being included, then they must be sufficient to store one day’s waste and have the necessary channels to collect all runoff and divert to the tank when deemed soiled water or to a safe clean water outlet when not in use.

Collective structures

The 200m2 figure is for these structures as a single entity. A second consideration states that the gross floor space of the proposed structure or any other such structure situated within the same farmyard complex or within 100m of the farmyard cannot exceed a total of 300m2 gross floor space. If it does, planning permission is required.

These structures cannot be constructed within 10m of a public road without planning permission, while no such structure can be constructed within 100m of any house (excluding the house of the person providing the structure), residential building, school, church, etc, without the written consent of the owner or, if appropriate, the occupier or person in charge.

Crush location

The rules pertaining to how cattle handling facilities can be constructed are detailed in the Department of Agriculture building specification S137 (May 2018); minimum specification for cattle crush, race and enclosure. This specification is also a useful guide for anyone erecting such facilities without looking for grant aid.

In terms of the siting of the crush, the specifications state that the crush and race can be free-standing, located alongside a mass concrete wall (a block wall is not sufficient), at the side of a suitable building or alternatively situated in an animal house or feed passage.

Understandably, the advice is to pay due regard to how animal penning divisions located in sheds and feed passages can combine with the unit. When the cattle crush and race is sited within a building, the crush needs to be faced towards light.

If the crush is to be used for caesarean sections and it runs alongside a wall, it is strongly recommended to run the crush from right to left so that there is free access to the left side of the animal.

Where availing of grant aid, the specifications state that there must be a minimum space of 4m and preferably 6m between the front end of the cattle crush and any facing wall, solid barrier or door that is less than 3m wide to allow cattle to exit the crush easily. Where a door is greater than 3m wide, the specifications state that the crush should be designed so that the door can be fully open when in use.

Crush dimensions

The crush length, which is defined as the first section joined to the head gate is recommended to be 1,4m in length where a skulling gate is in place, and 1.8m where a plain gate is in place. The head gate should be at least 1.6m in height and contain a quick-release mechanism. The minimum length of the race is 3.4m, while it is recommended to erect a race with a minimum length of 5.4m. As a guide, a 9m race is described as typically holding five to six mature animals.

There is a happy balance to be achieved to aid cattle flow, with long races holding 12 or more animals not recommended due to difficulties in encouraging animal flow. The standard width of the race is 650mm to 700mm.

Variations in size are permitted to suit different animal types, with 500mm recommended where the crush will be used exclusively for calves, 650mm to 700mm for dairy stock and up to 750mm for larger-framed beef animals.

Race design

The height of the top bar of the race section is recommended at 1.4m above ground level. Where again availing of grant aid, the minimum specification for uprights is tubular steel with an outer diameter (OD) of at least 76.1mm and thickness of 5mm or hollow-section boxed steel uprights measuring 80mm x 80mm x 4mm thick.

Upright posts should be set in a 300mm x 300mm x 450mm concrete base at no more than 2.4m centres. It is also strongly recommended that the post closest to the skulling gate be no more than 1.8m away from the gate and depending on the gate type possibly 1.4m. This spacing allows for the inclusion of a small swinging gate in the first section, which is highly recommended.

All of the rails or sections in the race must be fitted with a quick-release mechanism so they can be removed quickly and safely. In double-sided races, this quick-release mechanism only needs to be fitted on one side although the Department’s advice is to fit them on both sides if possible.

It is also recommended that races have a sliding or hinged gate at the back to prevent animals from reversing back into the forcing pen.

Height recommendation

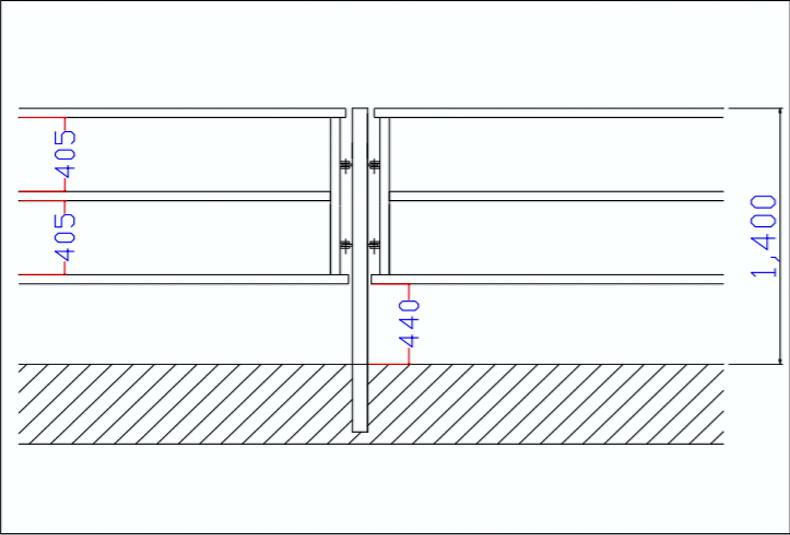

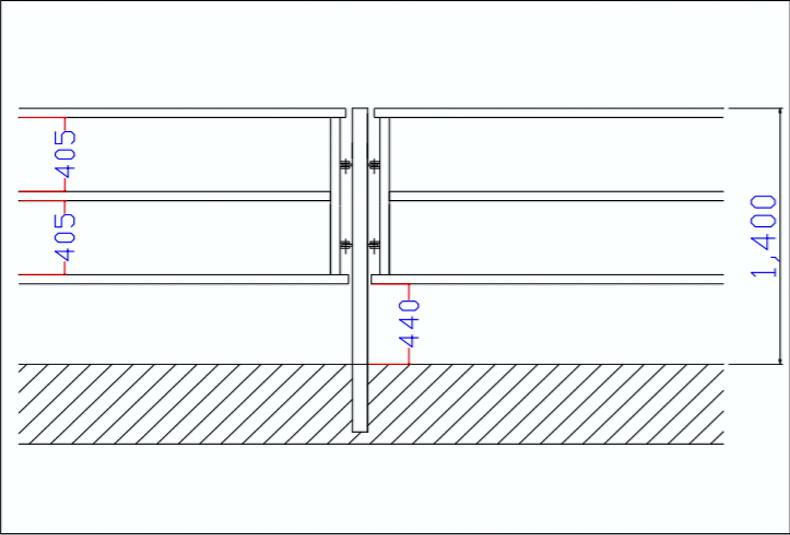

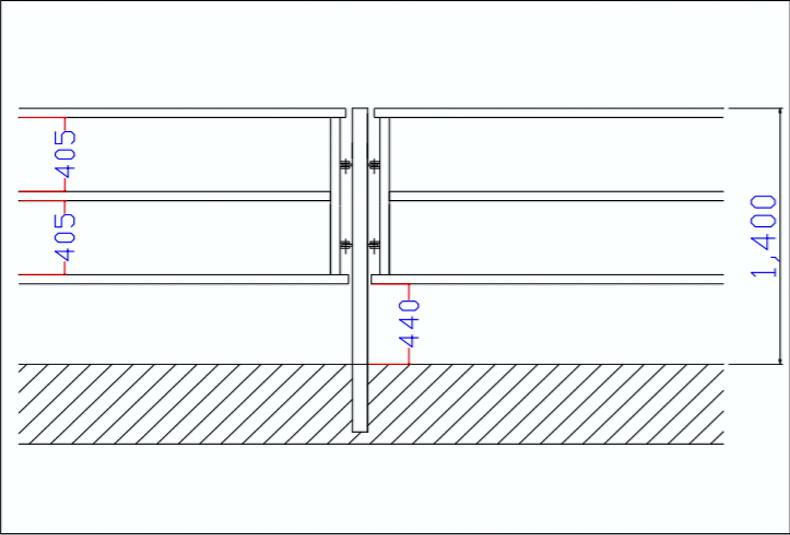

Figure 1 details the recommended rail height and spacing for a three-bar crush which is the minimum advised and permitted for grant aid.

Figure 1: Rail spacing and height for a three-rail crush and race

The space between the railings is recommended at 405mm which leaves a 440mm space from the bottom rail to ground floor height. All side rails, retaining bars or steel sections used in gates must be at least 48mm OD x 3mm thick or 50mm OD x 2mm for tubular steel and 50mm square sections x 2.5mm thick for box-type sections.

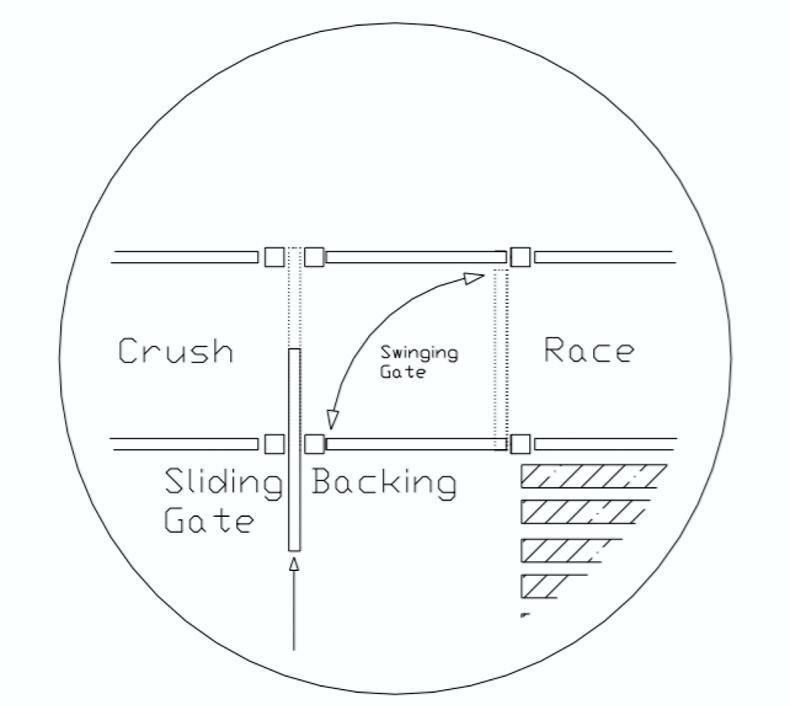

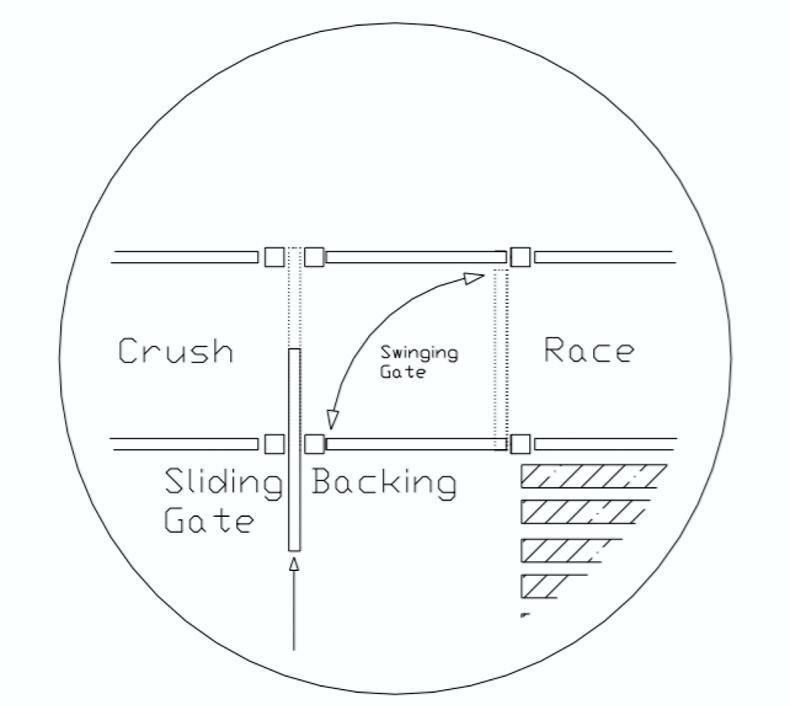

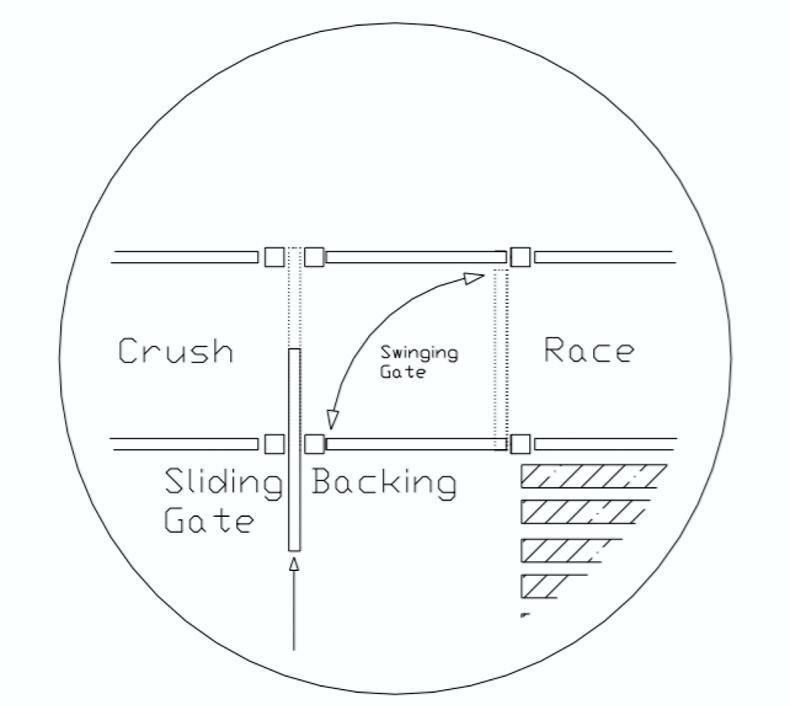

Installing a sliding or hinged gate at the rear of the crush, as demonstrated in Figure 2, is advised. This can then be used in conjunction with the swinging gate at the front of the crush to access the animal.

Figure 2: Sliding Gate at Rear of Crush & Swinging Gate at front of Race.

Alternatively, a tail bar or rump bar must be fitted at the rear of the crush (under TAMS).

The other option in this regard is to have suitable notches on the middle rails of the race (and wall if the crush is erected along a solid wall) to hold a retaining bar.

Floor

construction

For grant purposes, the floor area of the crush and race and an area extending to at least 600mm outside of this must be constructed with a 125mm thick concrete slab, which has been laid over a hardcore base of at least 150mm thick. The surface of the floor must be finished with a non-slip finish or diagonal grooves at intervals of 100mm to prevent animals slipping and provide for stress-free movement. A slope with a 1:60 fall shall be incorporated into the floor to prevent water buildup, with suitable drainage channels to receive runoff from the floor.

Catwalks are not mandatory but are advised. Where installed, the specification states a height of 300mm to 400mm and a width of at least 1.1m to facilitate a safe working area. It is also permissible to have variable-height catwalks. It is strongly recommended that at least 1.2m width of area along either side of the crush and race is excluded from any enclosure so as to provide a safe working area along the crush and race.

Forcing pen and surrounds

Another useful design component, irrespective of grant aid being sought, is a forcing pen. It should be funnel-shaped with one side straight and the other at a 300 angle to the race to encourage the free movement of cattle.

A circular forcing pen whereby the area can be reduced as animals enter the crush allows optimum control of animals.

Floor

The floor of the pen should also be a 125mm concrete base laid on a 150mm hardcore base. Concrete should also be finished with a non-slip finish or diagonal grooves with a slope of 1:60 also in place. Where the unit is not cleaned following use, drainage channels to collect runoff must be in place. The design of channels is 75mm wide by 75mm deep with the edges tapering slightly inwards.

A clean water diversion shall be in place for when the floor area is clean. Tanks must be built referring to S123, Minimum Specification for Bovine Livestock Units and Reinforced Tanks.

Existing walls or fences can form any part of the enclosure as long as they are at least 1.4m high and constructed of at least 150mm reinforced mass concrete for walls. For steel posts and rails, the post spacing cannot exceed 2.3m centres with at least three rails present. Where gates form part of the enclosure, they shall be constructed of a circular hollow section steel with at least a 48.3mm OD and 3mm thickness or square hollow section steel of 50mm x 50mm and 3mm thick.

Gates

Gates must be fitted with a heavy closing bolt. The bolt should be designed so it can be fully retracted into the gate frame. The maximum length of a gate is 4.6m, while ideally it is recommended that gates are no longer than 3m.

Hanging posts for gates must be at least 114.3mm OD by 3.6mm thick and closing posts shall be at least 88.9mm OD by 3mm thick.

Safety features: Each holding pen must provide at least one slip-through facility in all holding pens. The slip-through shall be constructed with a maximum width of 325mm. While it can improve efficiency and ease of movement through the unit, its major benefit is as an emergency exit to allow the handler to leave the pen quickly, if required. It is also recommended when designing a new unit to allow for a narrow 600mm-wide self-closing gate in each holding pen to allow quick access. Table 1 details the reference costs (exclusive of VAT) under the Targeted Agricultural Modernisation Scheme (TAMS) for the different components of a cattle handling pen.

Handling facilities are vital to the efficient running of any livestock enterprise. Good handling facilities reduce stress on the animal, prevent the risk of injury and also encourage regular handling of animals for management practices such as administering health treatments and weight recording.

There are a number of aspects that should be borne in mind when designing cattle handling facilities, irrespective of whether grant aid is being sought. The first of these is determining if planning permission is required.

Handling facilities are classified as a Class 8 structure under exempted development planning rules. Other structures in this class include roofless cubicles, open loose yards, self-feed silo or silage areas, feeding aprons, assembly yards, milking parlours or structures for the making or storage of silage. These structures must have an aggregate gross floor space that does not exceed 200m2 and also provide for effluent storage, where required.

Where the structure is cleaned after each use, there will generally not be any need for effluent/slurry storage. If storage facilities are being included, then they must be sufficient to store one day’s waste and have the necessary channels to collect all runoff and divert to the tank when deemed soiled water or to a safe clean water outlet when not in use.

Collective structures

The 200m2 figure is for these structures as a single entity. A second consideration states that the gross floor space of the proposed structure or any other such structure situated within the same farmyard complex or within 100m of the farmyard cannot exceed a total of 300m2 gross floor space. If it does, planning permission is required.

These structures cannot be constructed within 10m of a public road without planning permission, while no such structure can be constructed within 100m of any house (excluding the house of the person providing the structure), residential building, school, church, etc, without the written consent of the owner or, if appropriate, the occupier or person in charge.

Crush location

The rules pertaining to how cattle handling facilities can be constructed are detailed in the Department of Agriculture building specification S137 (May 2018); minimum specification for cattle crush, race and enclosure. This specification is also a useful guide for anyone erecting such facilities without looking for grant aid.

In terms of the siting of the crush, the specifications state that the crush and race can be free-standing, located alongside a mass concrete wall (a block wall is not sufficient), at the side of a suitable building or alternatively situated in an animal house or feed passage.

Understandably, the advice is to pay due regard to how animal penning divisions located in sheds and feed passages can combine with the unit. When the cattle crush and race is sited within a building, the crush needs to be faced towards light.

If the crush is to be used for caesarean sections and it runs alongside a wall, it is strongly recommended to run the crush from right to left so that there is free access to the left side of the animal.

Where availing of grant aid, the specifications state that there must be a minimum space of 4m and preferably 6m between the front end of the cattle crush and any facing wall, solid barrier or door that is less than 3m wide to allow cattle to exit the crush easily. Where a door is greater than 3m wide, the specifications state that the crush should be designed so that the door can be fully open when in use.

Crush dimensions

The crush length, which is defined as the first section joined to the head gate is recommended to be 1,4m in length where a skulling gate is in place, and 1.8m where a plain gate is in place. The head gate should be at least 1.6m in height and contain a quick-release mechanism. The minimum length of the race is 3.4m, while it is recommended to erect a race with a minimum length of 5.4m. As a guide, a 9m race is described as typically holding five to six mature animals.

There is a happy balance to be achieved to aid cattle flow, with long races holding 12 or more animals not recommended due to difficulties in encouraging animal flow. The standard width of the race is 650mm to 700mm.

Variations in size are permitted to suit different animal types, with 500mm recommended where the crush will be used exclusively for calves, 650mm to 700mm for dairy stock and up to 750mm for larger-framed beef animals.

Race design

The height of the top bar of the race section is recommended at 1.4m above ground level. Where again availing of grant aid, the minimum specification for uprights is tubular steel with an outer diameter (OD) of at least 76.1mm and thickness of 5mm or hollow-section boxed steel uprights measuring 80mm x 80mm x 4mm thick.

Upright posts should be set in a 300mm x 300mm x 450mm concrete base at no more than 2.4m centres. It is also strongly recommended that the post closest to the skulling gate be no more than 1.8m away from the gate and depending on the gate type possibly 1.4m. This spacing allows for the inclusion of a small swinging gate in the first section, which is highly recommended.

All of the rails or sections in the race must be fitted with a quick-release mechanism so they can be removed quickly and safely. In double-sided races, this quick-release mechanism only needs to be fitted on one side although the Department’s advice is to fit them on both sides if possible.

It is also recommended that races have a sliding or hinged gate at the back to prevent animals from reversing back into the forcing pen.

Height recommendation

Figure 1 details the recommended rail height and spacing for a three-bar crush which is the minimum advised and permitted for grant aid.

Figure 1: Rail spacing and height for a three-rail crush and race

The space between the railings is recommended at 405mm which leaves a 440mm space from the bottom rail to ground floor height. All side rails, retaining bars or steel sections used in gates must be at least 48mm OD x 3mm thick or 50mm OD x 2mm for tubular steel and 50mm square sections x 2.5mm thick for box-type sections.

Installing a sliding or hinged gate at the rear of the crush, as demonstrated in Figure 2, is advised. This can then be used in conjunction with the swinging gate at the front of the crush to access the animal.

Figure 2: Sliding Gate at Rear of Crush & Swinging Gate at front of Race.

Alternatively, a tail bar or rump bar must be fitted at the rear of the crush (under TAMS).

The other option in this regard is to have suitable notches on the middle rails of the race (and wall if the crush is erected along a solid wall) to hold a retaining bar.

Floor

construction

For grant purposes, the floor area of the crush and race and an area extending to at least 600mm outside of this must be constructed with a 125mm thick concrete slab, which has been laid over a hardcore base of at least 150mm thick. The surface of the floor must be finished with a non-slip finish or diagonal grooves at intervals of 100mm to prevent animals slipping and provide for stress-free movement. A slope with a 1:60 fall shall be incorporated into the floor to prevent water buildup, with suitable drainage channels to receive runoff from the floor.

Catwalks are not mandatory but are advised. Where installed, the specification states a height of 300mm to 400mm and a width of at least 1.1m to facilitate a safe working area. It is also permissible to have variable-height catwalks. It is strongly recommended that at least 1.2m width of area along either side of the crush and race is excluded from any enclosure so as to provide a safe working area along the crush and race.

Forcing pen and surrounds

Another useful design component, irrespective of grant aid being sought, is a forcing pen. It should be funnel-shaped with one side straight and the other at a 300 angle to the race to encourage the free movement of cattle.

A circular forcing pen whereby the area can be reduced as animals enter the crush allows optimum control of animals.

Floor

The floor of the pen should also be a 125mm concrete base laid on a 150mm hardcore base. Concrete should also be finished with a non-slip finish or diagonal grooves with a slope of 1:60 also in place. Where the unit is not cleaned following use, drainage channels to collect runoff must be in place. The design of channels is 75mm wide by 75mm deep with the edges tapering slightly inwards.

A clean water diversion shall be in place for when the floor area is clean. Tanks must be built referring to S123, Minimum Specification for Bovine Livestock Units and Reinforced Tanks.

Existing walls or fences can form any part of the enclosure as long as they are at least 1.4m high and constructed of at least 150mm reinforced mass concrete for walls. For steel posts and rails, the post spacing cannot exceed 2.3m centres with at least three rails present. Where gates form part of the enclosure, they shall be constructed of a circular hollow section steel with at least a 48.3mm OD and 3mm thickness or square hollow section steel of 50mm x 50mm and 3mm thick.

Gates

Gates must be fitted with a heavy closing bolt. The bolt should be designed so it can be fully retracted into the gate frame. The maximum length of a gate is 4.6m, while ideally it is recommended that gates are no longer than 3m.

Hanging posts for gates must be at least 114.3mm OD by 3.6mm thick and closing posts shall be at least 88.9mm OD by 3mm thick.

Safety features: Each holding pen must provide at least one slip-through facility in all holding pens. The slip-through shall be constructed with a maximum width of 325mm. While it can improve efficiency and ease of movement through the unit, its major benefit is as an emergency exit to allow the handler to leave the pen quickly, if required. It is also recommended when designing a new unit to allow for a narrow 600mm-wide self-closing gate in each holding pen to allow quick access. Table 1 details the reference costs (exclusive of VAT) under the Targeted Agricultural Modernisation Scheme (TAMS) for the different components of a cattle handling pen.

SHARING OPTIONS