Over the past seven years, Martin and Marie Keating, who farm 20ha in Doon, outside Westport, Co Mayo, have been building up their dairy calf-to-beef enterprise.

Every year, the system is tweaked or changed slightly in order to make it work better the following year.

Each change is carefully planned and meticulously thought out by the Keatings, which is why performance of the system continues to improve year-on-year.

Soil fertility and grassland

management

The first change was in grass and grazing. Over the last number of years, there has been a big investment in soil fertility, reseeding, grazing infrastructure, farm roadways and increasing the number of paddocks and divisions on-farm so as to make best use of every kilo of grass the farm grows.

Often people see rehousing cattle in spring as a failure, but we look at it differently here

Yearling heifers were turned out on the 1 March this year, as ground conditions were good and there was plenty of grass on the farm. A few days of wet weather saw them rehoused for a week until the ground soaked out once again.

Martin Keating, Westport, Co Mayo.

A good network of farm roadways means bringing heifers back in is a one person job and Martin says that you need to be flexible with your approach to grazing in early spring.

“Often people see rehousing cattle in spring as a failure, but we look at it differently here. We managed to get 10 full days at grass in early March, which is a big saving for us.”

Genetics

The second step in building the system occurred when the farm joined the Thrive programme. This meant that the farm was now rearing all AI-sired calves from high dairy beef index (DBI) bulls. The family decided to go down the 19 month heifer route, with Angus being the breed of choice.

“Angus heifers are ideal for the farm here, we can get them finished off grass at the end of the grazing season without any issues. Demand from processors for these types of cattle has also played a role in the decision.”

Building numbers

In 2019, 34 calves were reared, and last year that increased to 44 heifers. A fortnight ago, 45 calves arrived on-farm for the 2021 year.

“I would have liked to push it to 50 calves this year, but we are curtailed in order to hit the 5% reduction in organic nitrogen in the BEAM scheme. We are on target for the end of June deadline, so I will reassess things after that.”

Commenting on calf price this year, Martin said that it was definitely at the top end of the budget, with an average price of €185/head, up €22/head on last year.

“It is a balancing act – I cannot afford to pay too much for calves, but I also need an early spring-born calf in order to have them slaughtered at the end of the second grazing season. Late March or April-born calves do not fit this system at any price.”

Housing facilities

This year saw what could be the final major step to improve the overall system, with the expansion of the calf rearing shed and installation of an automatic calf feeder.

We added a 20ft bay on the front of the shed, but also changed the layout completely

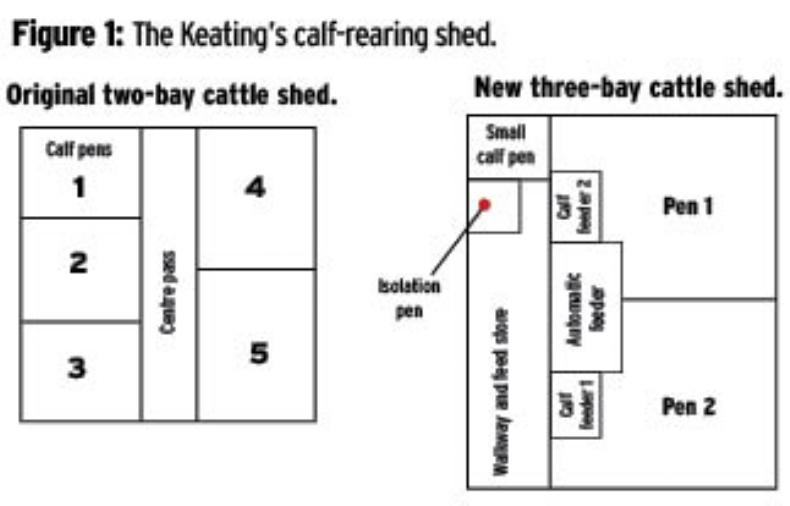

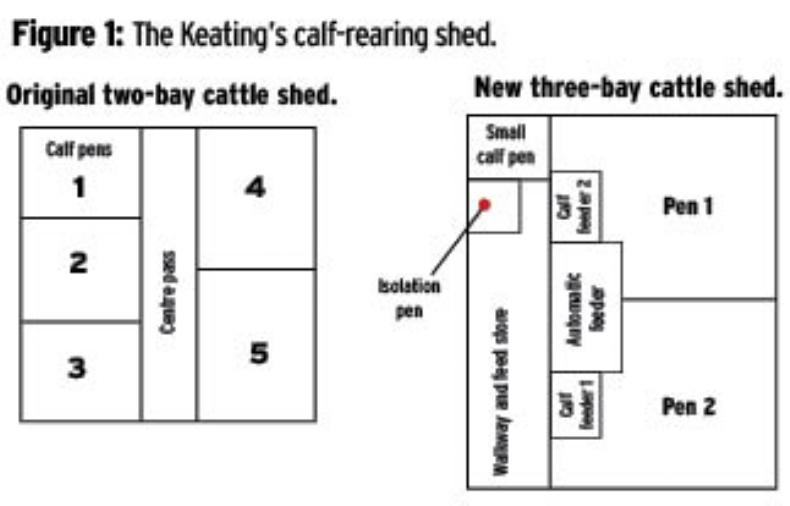

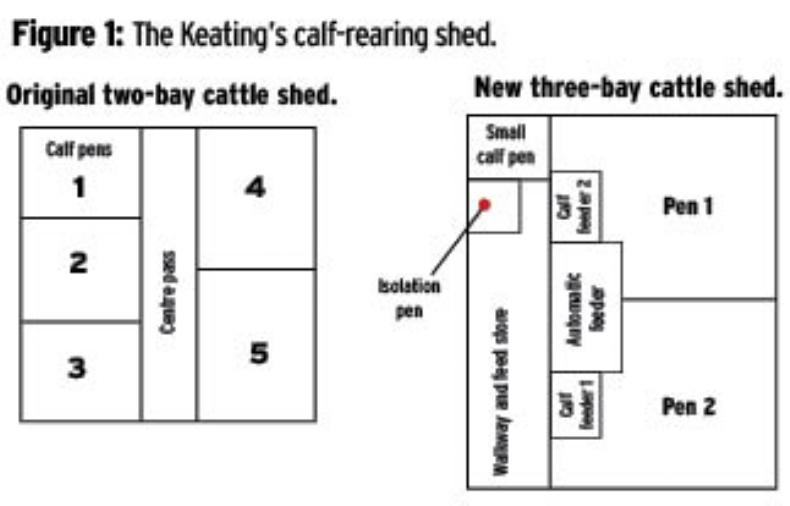

The calf rearing shed was a two-bay, dry-floor shed that had three pens on one side and two on the other. Over the last few months, Martin has added an extra bay to the shed in order to increase capacity.

“We added a 20ft bay on the front of the shed, but also changed the layout completely in order to make best use of space and make things easier for the automatic feeder. It did mean having to re-concrete much of the shed in order to have drainage and slopes on floors correct, but it has future-proofed the rearing system on-farm.”

Figure 1 outlines the changes made to the calf rearing shed setup. Instead of calf pens left and right, two large pens run the length of the right hand side of the shed. On the left is a pass, feed and bedding store, as well as an isolation pen and a small pen for any calves that need extra attention.

Automatic feeder

The decision to go down the automatic calf feeder route this spring was carefully considered. Martin said the main reason for doing so was to be able to increase the number of calves that were being reared at one time on-farm, without increasing the amount of labour. Both Martin and Marie work off-farm, so the labour saving element played a key role in the decision.

“Instead of spending a couple of hours in the shed morning and evening just feeding calves, we can now spend the time managing performance and making sure every other aspect of the rearing system is optimal for calves to perform. We opted to go for the JFC evolution S2, which can feed up to 70 calves at a time, so there is room for further expansion if we choose to do so.

“While we are just a couple of weeks in, I am very happy with the system so far. It has been relatively simple for both us and the calves to get trained in on. Each day is broken into three eight-hour periods, with calves having a certain allowance of milk in each period.

What I really like about the system is that I have real-time data on my phone to see how things are going

“The system also has a built in feed curve that allows you to build up milk feeding over a certain number of days. Calves were initially getting 4l/day, which has been built up over a 10 day period to 6l/day. Likewise for weaning, this can all be automatically managed.

“What I really like about the system is that I have real-time data on my phone to see how things are going, even when I am away at work. I can see when calves have not drunk their allowance in any given period and it is a great way to identify any sickness at the earliest possible point.

“While it is a big investment, when you cost it out over the lifetime of the machine, alongside the labour saving element with us working off-farm, it was the right choice for our situation.”

Martin and Marie

Keating.Doon, Westport, Co Mayo.20ha farm.44 yearling.heifers.45 calves being reared this year.

Over the past seven years, Martin and Marie Keating, who farm 20ha in Doon, outside Westport, Co Mayo, have been building up their dairy calf-to-beef enterprise.

Every year, the system is tweaked or changed slightly in order to make it work better the following year.

Each change is carefully planned and meticulously thought out by the Keatings, which is why performance of the system continues to improve year-on-year.

Soil fertility and grassland

management

The first change was in grass and grazing. Over the last number of years, there has been a big investment in soil fertility, reseeding, grazing infrastructure, farm roadways and increasing the number of paddocks and divisions on-farm so as to make best use of every kilo of grass the farm grows.

Often people see rehousing cattle in spring as a failure, but we look at it differently here

Yearling heifers were turned out on the 1 March this year, as ground conditions were good and there was plenty of grass on the farm. A few days of wet weather saw them rehoused for a week until the ground soaked out once again.

Martin Keating, Westport, Co Mayo.

A good network of farm roadways means bringing heifers back in is a one person job and Martin says that you need to be flexible with your approach to grazing in early spring.

“Often people see rehousing cattle in spring as a failure, but we look at it differently here. We managed to get 10 full days at grass in early March, which is a big saving for us.”

Genetics

The second step in building the system occurred when the farm joined the Thrive programme. This meant that the farm was now rearing all AI-sired calves from high dairy beef index (DBI) bulls. The family decided to go down the 19 month heifer route, with Angus being the breed of choice.

“Angus heifers are ideal for the farm here, we can get them finished off grass at the end of the grazing season without any issues. Demand from processors for these types of cattle has also played a role in the decision.”

Building numbers

In 2019, 34 calves were reared, and last year that increased to 44 heifers. A fortnight ago, 45 calves arrived on-farm for the 2021 year.

“I would have liked to push it to 50 calves this year, but we are curtailed in order to hit the 5% reduction in organic nitrogen in the BEAM scheme. We are on target for the end of June deadline, so I will reassess things after that.”

Commenting on calf price this year, Martin said that it was definitely at the top end of the budget, with an average price of €185/head, up €22/head on last year.

“It is a balancing act – I cannot afford to pay too much for calves, but I also need an early spring-born calf in order to have them slaughtered at the end of the second grazing season. Late March or April-born calves do not fit this system at any price.”

Housing facilities

This year saw what could be the final major step to improve the overall system, with the expansion of the calf rearing shed and installation of an automatic calf feeder.

We added a 20ft bay on the front of the shed, but also changed the layout completely

The calf rearing shed was a two-bay, dry-floor shed that had three pens on one side and two on the other. Over the last few months, Martin has added an extra bay to the shed in order to increase capacity.

“We added a 20ft bay on the front of the shed, but also changed the layout completely in order to make best use of space and make things easier for the automatic feeder. It did mean having to re-concrete much of the shed in order to have drainage and slopes on floors correct, but it has future-proofed the rearing system on-farm.”

Figure 1 outlines the changes made to the calf rearing shed setup. Instead of calf pens left and right, two large pens run the length of the right hand side of the shed. On the left is a pass, feed and bedding store, as well as an isolation pen and a small pen for any calves that need extra attention.

Automatic feeder

The decision to go down the automatic calf feeder route this spring was carefully considered. Martin said the main reason for doing so was to be able to increase the number of calves that were being reared at one time on-farm, without increasing the amount of labour. Both Martin and Marie work off-farm, so the labour saving element played a key role in the decision.

“Instead of spending a couple of hours in the shed morning and evening just feeding calves, we can now spend the time managing performance and making sure every other aspect of the rearing system is optimal for calves to perform. We opted to go for the JFC evolution S2, which can feed up to 70 calves at a time, so there is room for further expansion if we choose to do so.

“While we are just a couple of weeks in, I am very happy with the system so far. It has been relatively simple for both us and the calves to get trained in on. Each day is broken into three eight-hour periods, with calves having a certain allowance of milk in each period.

What I really like about the system is that I have real-time data on my phone to see how things are going

“The system also has a built in feed curve that allows you to build up milk feeding over a certain number of days. Calves were initially getting 4l/day, which has been built up over a 10 day period to 6l/day. Likewise for weaning, this can all be automatically managed.

“What I really like about the system is that I have real-time data on my phone to see how things are going, even when I am away at work. I can see when calves have not drunk their allowance in any given period and it is a great way to identify any sickness at the earliest possible point.

“While it is a big investment, when you cost it out over the lifetime of the machine, alongside the labour saving element with us working off-farm, it was the right choice for our situation.”

Martin and Marie

Keating.Doon, Westport, Co Mayo.20ha farm.44 yearling.heifers.45 calves being reared this year.

SHARING OPTIONS