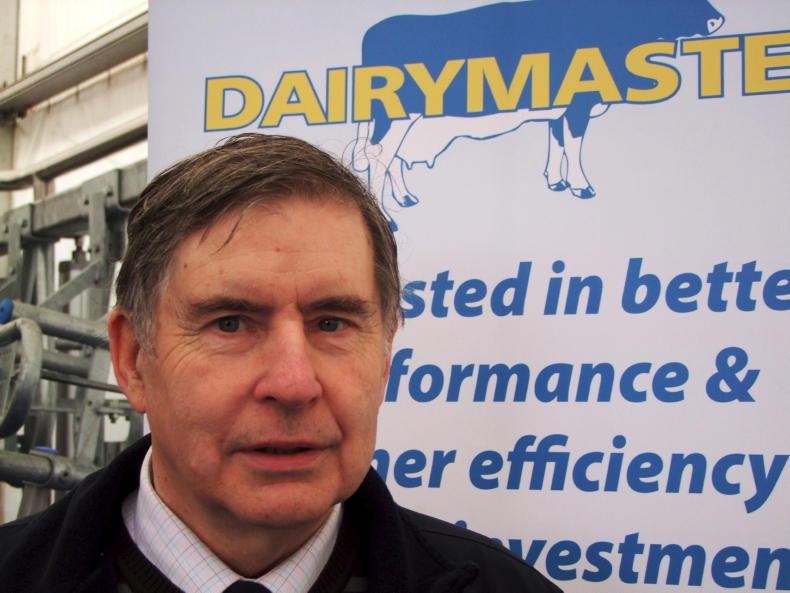

Dr Edmond Harty, the CEO of well-known Irish milking equipment company Dairymaster, has announced he is leaving the company to pursue other interests. Harty, who was named as the EY Entrepreneur of the Year in 2012, is very much the face of Dairymaster and has driven the business into new areas for milking equipment such as artificial intelligence (AI), sensors, robotics and data technology.

“I’ve announced today that I will be moving on from Dairymaster to pursue other interests.

I’m delighted to be leaving the business in such a strong position, as a leading international high-tech dairy equipment manufacturer, and I’m very proud of our innovation-led achievements over my tenure,” said Harty.

“For the immediate future, I plan to take a little time out and to avail of the opportunity to spend more time with my family. Going forward, I intend to pursue and develop other new projects and initiatives using the magical combination of innovation, technology and business. I will keep you posted,” he added.

Technology

Based in Causeway, Co Kerry, Dairymaster has grown into a large scale business exporting milking machines, bulk tanks, automated feeding systems and manure scrapers as well as cutting edge herd health monitoring devices to dairy farms all over the world.

Almost three quarters of the group’s sales are generated in over 40 export markets, including the US, Japan, Russia and the UK. In Germany, Dairymaster has grown to account for 25% of the milking machine market.

Dairymaster history

Dairymaster was founded in 1968 by Ned Harty, Edmond’s father. The company first began exporting milking parlours to the UK market in the 1980’s and has since grown its export business to markets all over the world.

Today, the company employs almost 400 people at its 11-acre manufacturing facility in Causeway, Co Kerry.

Innovation

Last year, Dairymaster won the top award at the 2019 Innovation Arena run by Enterprise Ireland at the National Ploughing Championships for its Mission Control system - a self-learning computer programme which optimises carousel speed in rotary parlours.

The system uses a technology called OptiCruise to adjust the speed of milking so that milking time is optimised and cows are not idle on the rotary.

Dairymaster’s Mission Control system also uses artificial intelligence technology to recognise individual cows in the herd.

Known as CowNow, this artificial intelligence technology identifies the history of each individual cow, predicts its milk out time and combines it with the milk out time of the cows already featured on the problem.

SHARING OPTIONS