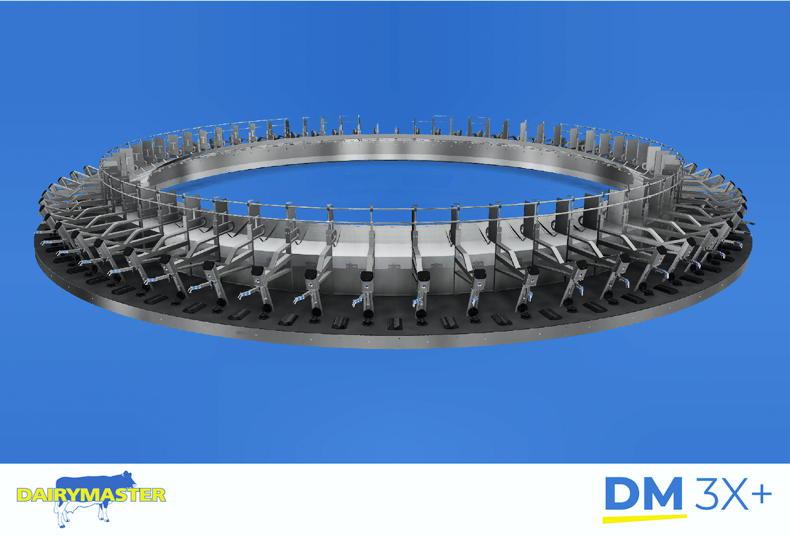

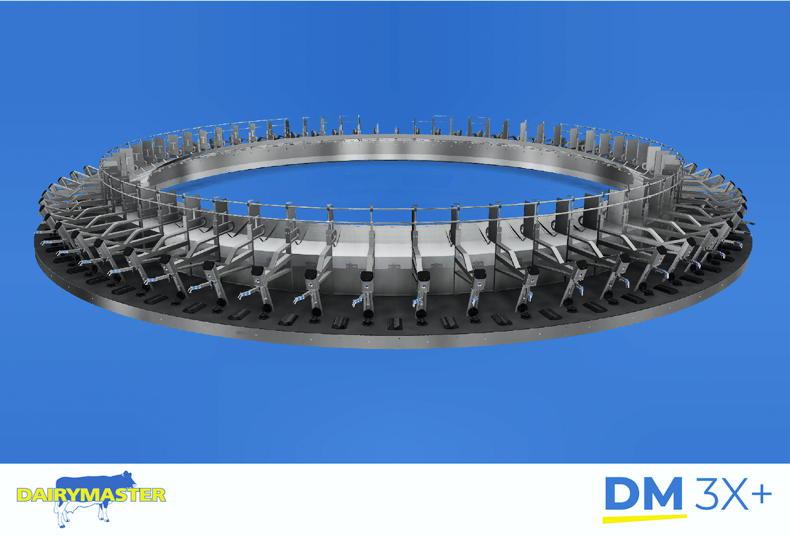

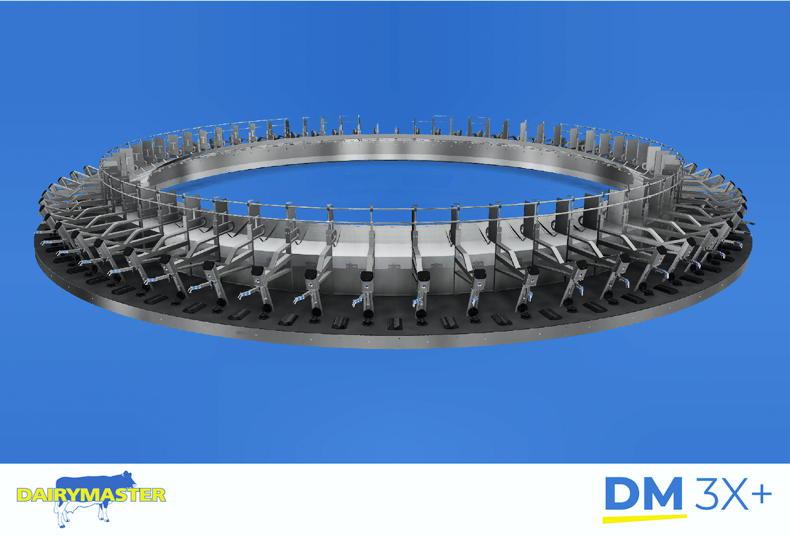

Dairymaster, the Kerry-based global milking machine manufacturer, has launched a new rotary milking parlour called the DM3X, which is designed to suit very large dairy farms.

The rotary has been fully redesigned with sleeker style and ergonomic stall work, along with a more streamlined operator interface with colour-coded commands.

One of the key aspects of the new rotary is that it is designed for continuous operation, with built-in redundancy, meaning that if one part breaks down, the machine will continue operating at full capacity.

According to Dairymaster’s Dr John Daly, this level of performance is key when there are large herds with perhaps thousands of cows being milked three or even four times per day.

Maintenance

“Finding time to do maintenance on these parlours is difficult because there is very little downtime. Think of it as a Formula One pit stop as opposed to leaving a car into a garage for the day,” he said.

He said that a rotary parlour in a very large herd that’s operating for 24 hours per day will do the same work in one year as a rotary parlour milking 300 cows in Ireland will do over 10.5 years, so this is something they have factored into their new rotary.

Another new innovation by Dairymaster is the new Swiftflo personalised milking platform, which has three different parts to it:

Increased pulsation rate for the first 60 seconds of cluster attachment to stimulate milk let down.Dynamic pulsation rate and ratio depending on the stage of milk out.Variable take-off, meaning the ACR will remove the cluster at a lower milk flow than a higher-yielding cow.The new system works in conjunction with the DairyVue software platform, which has been completely redesigned over the last few years.

At present, personalised milking is only available for rotary parlours, but Dairymaster says it will be rolling it out to all parlours soon.

New innovation

Another new innovation launched by Dairymaster is a robotic teat sprayer, again for rotary parlours. This automatically sprays cows’ teats after milking, which reduces labour requirements on large farms.

Image of new Dairymaster DM3X rotary milking parlour.

Speaking at the launch of the new products, Dairymaster CEO John Harty said that the company continues to grow and continues to gain market share, with 75% of all products exported and 95% of all products manufactured in-house.

International business manager Fergus O’Meara praised the work of the CEO: “Since John was appointed CEO, the values and principles of Dairymaster have been reignited. John is a real people person and he empowers the team. He is the main driver behind these new products.”

The new products will be on display at the Dairymaster stand at the National Ploughing Championships.

Dairymaster, the Kerry-based global milking machine manufacturer, has launched a new rotary milking parlour called the DM3X, which is designed to suit very large dairy farms.

The rotary has been fully redesigned with sleeker style and ergonomic stall work, along with a more streamlined operator interface with colour-coded commands.

One of the key aspects of the new rotary is that it is designed for continuous operation, with built-in redundancy, meaning that if one part breaks down, the machine will continue operating at full capacity.

According to Dairymaster’s Dr John Daly, this level of performance is key when there are large herds with perhaps thousands of cows being milked three or even four times per day.

Maintenance

“Finding time to do maintenance on these parlours is difficult because there is very little downtime. Think of it as a Formula One pit stop as opposed to leaving a car into a garage for the day,” he said.

He said that a rotary parlour in a very large herd that’s operating for 24 hours per day will do the same work in one year as a rotary parlour milking 300 cows in Ireland will do over 10.5 years, so this is something they have factored into their new rotary.

Another new innovation by Dairymaster is the new Swiftflo personalised milking platform, which has three different parts to it:

Increased pulsation rate for the first 60 seconds of cluster attachment to stimulate milk let down.Dynamic pulsation rate and ratio depending on the stage of milk out.Variable take-off, meaning the ACR will remove the cluster at a lower milk flow than a higher-yielding cow.The new system works in conjunction with the DairyVue software platform, which has been completely redesigned over the last few years.

At present, personalised milking is only available for rotary parlours, but Dairymaster says it will be rolling it out to all parlours soon.

New innovation

Another new innovation launched by Dairymaster is a robotic teat sprayer, again for rotary parlours. This automatically sprays cows’ teats after milking, which reduces labour requirements on large farms.

Image of new Dairymaster DM3X rotary milking parlour.

Speaking at the launch of the new products, Dairymaster CEO John Harty said that the company continues to grow and continues to gain market share, with 75% of all products exported and 95% of all products manufactured in-house.

International business manager Fergus O’Meara praised the work of the CEO: “Since John was appointed CEO, the values and principles of Dairymaster have been reignited. John is a real people person and he empowers the team. He is the main driver behind these new products.”

The new products will be on display at the Dairymaster stand at the National Ploughing Championships.

SHARING OPTIONS