We have probably reached peak grass on the farm this week, with the farm cover sitting at over 1,300kg of dry matter per hectare (DM/ha) for most of the first half of September.

We spread the last of the fertiliser earlier this week with two loads of CAN blanket spread across the farm. Hopefully, this will keep grass growth moving along well into October. We will feed 3kg of meal for the next few weeks to keep cows milking well on high covers and hopefully to keep cows out grazing for as long as possible into the autumn.

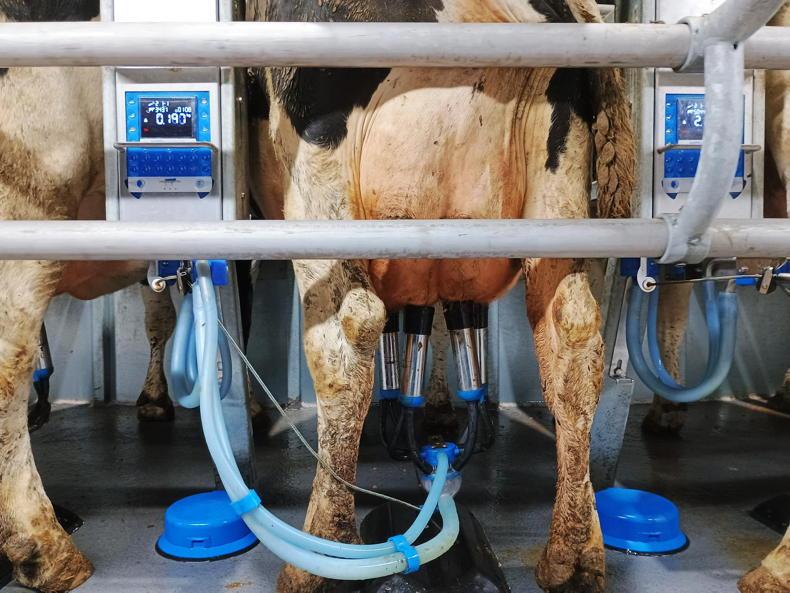

The grass covers are a bit high but quality seems excellent and milk production is holding up well at 18 litres with butterfat over 4.7% and protein just short of 3.9%. We are just starting to drop under 1.6kg of milk solids this week.

We should hit 4% protein and 5% fat later this month, which is probably a bit later than most herds with more Jersey crossbred influence but the litres are holding up very well on the other side of the equation.

We will concentrate on slurry for the next few weeks and get the tanks empty before the deadline next month. We will spread the outfarm and some of the fields at home with our own tanker and switch to an umbilical system for the closer fields at home. A dribblebar on the umbilical system will make it easier to spread some fields with a cover of grass on them. The other advantage of the umbilical system is keeping the heavy machinery off the main farm roadways.

It’s been an exceptional grass growing year on the farm so far, with silage bales taken off the milking platform every month from April to the end of August. We have just over 12t of grass grown to date and should hit just over 14t by the end of the year.

A group of us went to Wales last week to see a few top-class farms. We saw a good cross-section of farms with everything from spring-calving, Irish-type grazing systems with some crossbred cows to a full indoor US-style system with a herd of 800 pedigree Holstein cows averaging over 12,000 litres.

The indoor system was at least as profitable as the outdoor system when run to a very high standard and the return on investment was higher with the indoor system but the eye can’t be taken off the ball at any stage of the year, with everything a lot more intense in that system.

Pressure

There is a lot of pressure on the farm owners or farm managers on the indoor farms, with targets to meet and protocols to implement every day of the year.

The spring-calving farmers were very relaxed in comparison and, while the workload on the spring systems would be a lot higher through the spring months, there was a lot more opportunity to take a bit more time off and step back from the business in the second half of the year.

Both systems were financially rewarding, especially with the rising milk price, and the cows were well looked after in both indoors and out. Just the stress and strain and the need to run at 100% efficiency all the time with the indoor system would turn most of us away from this model.

SHARING OPTIONS