Brian O’Reilly decided to make a change having exited the mushroom market and is now growing greens in his former mushroom tunnels using hydroponics – growing plants on water instead of soil.

As consumers become more aware of the impact their food has on the environment around them, and on the standards kept in producing that food, local, sustainable produce is coming into the spotlight.

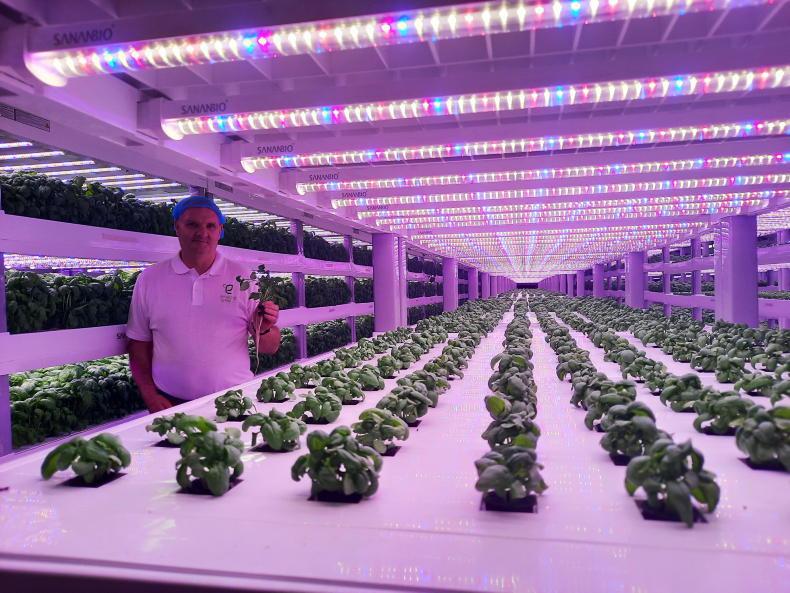

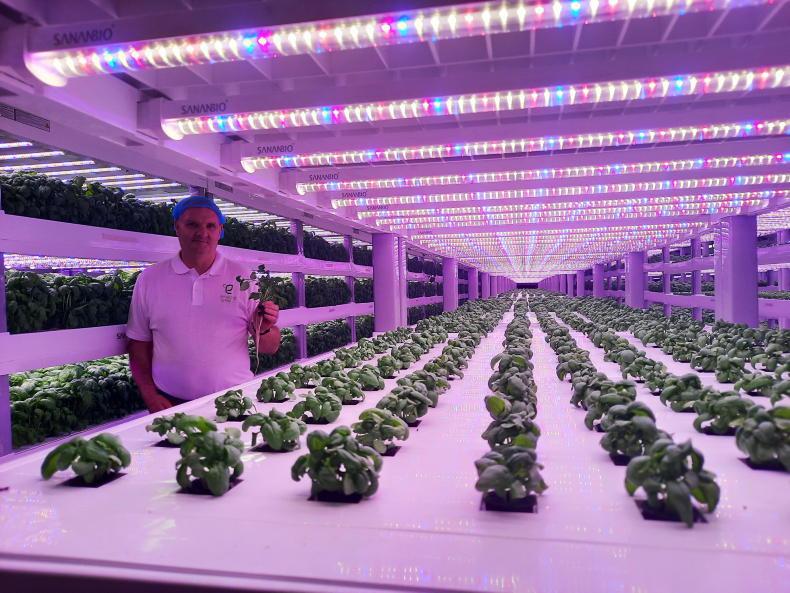

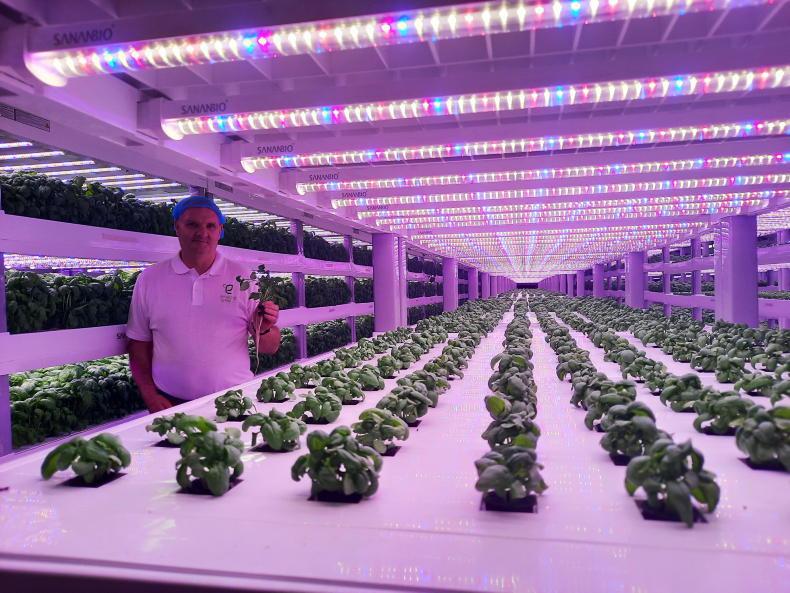

Brian O'Reilly at Emerald Greens.

However, there is still a long way to go as consumers demand product that is out of season in Ireland, but hydroponics can overcome this issue.

For instance, the basil that Brian grows, along with his wife Lucy, usually has a three-month growing season in Ireland.

Using a controlled environment, Brian grows basil all year round and has plans to expand. So instead of basil travelling thousands of kilometres to your local shop, it is simply making its way onto the nearby M8 motorway to its final destination within the island’s shorelines.

The produce is fresher, the food miles are lower, the shelf-life is longer and the product is highly-traceable and sustainable.

Brian O'Reilly, Emerald Greens; Shay Kendrick, Compass Ireland; and Richard Murray, Compass Ireland.

Brian was a mushroom farmer for 18 years. Originally from Dublin, he did the Farm Apprenticeship Programme and worked on dairy and pig farms as a farm manager before starting his own mushroom farm.

He grew chestnut mushrooms, but as the return from mushrooms became tighter and was going to require more investment without support, he exited the industry in 2018.

As the mushroom tunnels lay idle, a trip to see his daughter in Dubai inspired Brian to investigate hydroponics, as he saw shelves of greens growing in supermarkets.

This led him to convert a mushroom tunnel into a vertical, hydroponic farm using the Sananbio system provided by Farmony.

Basil growing hydroponically at Emerald Greens.

The first mushroom tunnel was converted and has been growing greens since December 2020. A second tunnel is now under conversion.

Brian has also grown mixed greens and coriander, but the tunnel is now dedicated to basil and a second tunnel will facilitate mixed greens.

He may venture into plants like cucumber in time, but these have a longer growing season and turn around time, which dents productivity and a return needs to be made.

The units cost €2,000 each and there are 70 in the tunnel. Having the tunnels in place, along with ventilation from the mushroom business, has helped to reduce costs, but this is still a major investment. The horticultural grant of 40% was available on the investment for the equipment.

Basil growing at Emerald Greens.

How does it work?

Eight to 10 seeds are placed in individual slots within plastic trays in a small amount of growing medium made up of peat and binding ingredients. Once the seeds are planted they take 15 days to reach the modules.

The seedlings are then moved to the trays and sit above 20l of water, which is pumped from a 1,500l tank. Liquid nutrients are added to this water.

A view of one of the tunnels at Emerald Greens.

In the case of basil, it’s just nitrogen, phosphorus and potassium, but this changes depending on the crop – for example, magnesium was added to the coriander. A pH of 6.0 is needed in the water for basil.

The nutrients are added to the water and after this, it’s about keeping disease at bay. The tunnel is a controlled environment, kept at 22.5°C, while the water is at 23°C.

The plants grow on water which nutrients are added to.

The relative humidity in the tunnel is kept at 70-80°C. The modules are also cleaned every six weeks. Pests have not been a problem for Brian so far, but he is watching for insects on sticky traps.

A wind turbine helps to support the farms energy needs.

Once in the modules, the plants grow for 15-18 days. At present, Brian harvests on a Monday and product is delivered on a Tuesday.

There is a lot of intricate work involved at both the planting and harvesting stage, but Brian is clearly enjoying the new challenge.

His brother Aidan has come on board and the pair formed the company Emerald Greens. Aidan will manage sales and marketing.

The LED lights sit over the trays of greens.

Demand for local

The demand for local food is increasing. For example, the expansion of the business is being supported by Compass Group Ireland, a catering company and their logistics food service partner Ready Chef.

These partners will purchase 25% of the basil produced on the farm each week. This equates to about 200kg of basil.

Shay Kendrick is the culinary director at Compass Group Ireland and says that people are starting to think more about where and how their food is grown.

“People want local. They want to know where their chicken’s coming from. They want to know where their herbs and basil are coming from.”

Richard Murray, the executive chef for Compass Group Ireland at Google, stated: “We want to be a stone’s throw away from all ingredients. We don’t really want to be importing ingredients.

Brian O’Reilly decided to make a change having exited the mushroom market and is now growing greens in his former mushroom tunnels using hydroponics – growing plants on water instead of soil.

As consumers become more aware of the impact their food has on the environment around them, and on the standards kept in producing that food, local, sustainable produce is coming into the spotlight.

Brian O'Reilly at Emerald Greens.

However, there is still a long way to go as consumers demand product that is out of season in Ireland, but hydroponics can overcome this issue.

For instance, the basil that Brian grows, along with his wife Lucy, usually has a three-month growing season in Ireland.

Using a controlled environment, Brian grows basil all year round and has plans to expand. So instead of basil travelling thousands of kilometres to your local shop, it is simply making its way onto the nearby M8 motorway to its final destination within the island’s shorelines.

The produce is fresher, the food miles are lower, the shelf-life is longer and the product is highly-traceable and sustainable.

Brian O'Reilly, Emerald Greens; Shay Kendrick, Compass Ireland; and Richard Murray, Compass Ireland.

Brian was a mushroom farmer for 18 years. Originally from Dublin, he did the Farm Apprenticeship Programme and worked on dairy and pig farms as a farm manager before starting his own mushroom farm.

He grew chestnut mushrooms, but as the return from mushrooms became tighter and was going to require more investment without support, he exited the industry in 2018.

As the mushroom tunnels lay idle, a trip to see his daughter in Dubai inspired Brian to investigate hydroponics, as he saw shelves of greens growing in supermarkets.

This led him to convert a mushroom tunnel into a vertical, hydroponic farm using the Sananbio system provided by Farmony.

Basil growing hydroponically at Emerald Greens.

The first mushroom tunnel was converted and has been growing greens since December 2020. A second tunnel is now under conversion.

Brian has also grown mixed greens and coriander, but the tunnel is now dedicated to basil and a second tunnel will facilitate mixed greens.

He may venture into plants like cucumber in time, but these have a longer growing season and turn around time, which dents productivity and a return needs to be made.

The units cost €2,000 each and there are 70 in the tunnel. Having the tunnels in place, along with ventilation from the mushroom business, has helped to reduce costs, but this is still a major investment. The horticultural grant of 40% was available on the investment for the equipment.

Basil growing at Emerald Greens.

How does it work?

Eight to 10 seeds are placed in individual slots within plastic trays in a small amount of growing medium made up of peat and binding ingredients. Once the seeds are planted they take 15 days to reach the modules.

The seedlings are then moved to the trays and sit above 20l of water, which is pumped from a 1,500l tank. Liquid nutrients are added to this water.

A view of one of the tunnels at Emerald Greens.

In the case of basil, it’s just nitrogen, phosphorus and potassium, but this changes depending on the crop – for example, magnesium was added to the coriander. A pH of 6.0 is needed in the water for basil.

The nutrients are added to the water and after this, it’s about keeping disease at bay. The tunnel is a controlled environment, kept at 22.5°C, while the water is at 23°C.

The plants grow on water which nutrients are added to.

The relative humidity in the tunnel is kept at 70-80°C. The modules are also cleaned every six weeks. Pests have not been a problem for Brian so far, but he is watching for insects on sticky traps.

A wind turbine helps to support the farms energy needs.

Once in the modules, the plants grow for 15-18 days. At present, Brian harvests on a Monday and product is delivered on a Tuesday.

There is a lot of intricate work involved at both the planting and harvesting stage, but Brian is clearly enjoying the new challenge.

His brother Aidan has come on board and the pair formed the company Emerald Greens. Aidan will manage sales and marketing.

The LED lights sit over the trays of greens.

Demand for local

The demand for local food is increasing. For example, the expansion of the business is being supported by Compass Group Ireland, a catering company and their logistics food service partner Ready Chef.

These partners will purchase 25% of the basil produced on the farm each week. This equates to about 200kg of basil.

Shay Kendrick is the culinary director at Compass Group Ireland and says that people are starting to think more about where and how their food is grown.

“People want local. They want to know where their chicken’s coming from. They want to know where their herbs and basil are coming from.”

Richard Murray, the executive chef for Compass Group Ireland at Google, stated: “We want to be a stone’s throw away from all ingredients. We don’t really want to be importing ingredients.

SHARING OPTIONS