Land use and farming practices are evolving, and it is now all but certain that carbon farming will soon become a reality.

Anaerobic digestion (AD) technology is set to play a crucial role in this transition, as highlighted by an international panel discussion during the recent launch of the Irish Farmers Journal/KPMG magazine in Kildare last week.

The panellists included Jan Cees Vogelaar, a co-founder of Dutch Carbon Credits; Neil Fuller, a soil scientist who works closely with the UK consultancy, Future Food Solution; and Philipp Lukas, CEO of UK-based Future Biogas.

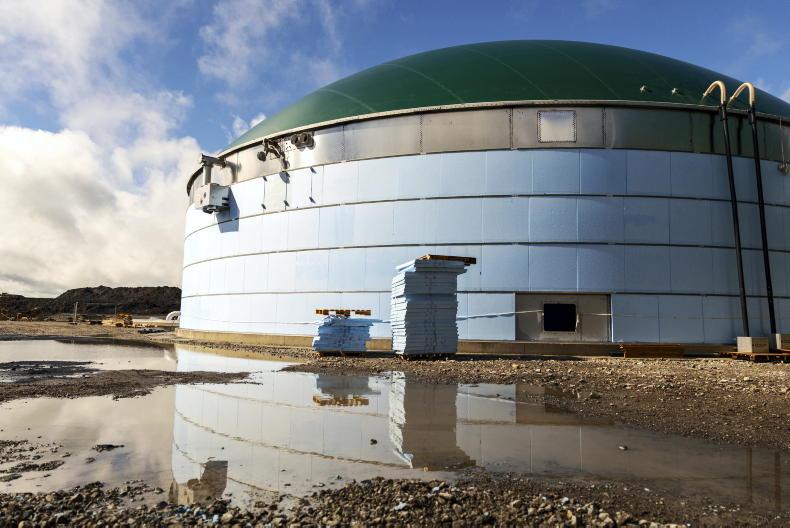

Future Biogas has built and now operate 12 agricultural-based AD plants across southeast England. Over 90% of the feedstock is supplied by agricultural crops, grown by 450 farms all within 12 miles of the plants.

Founded in 2010, the company now produce 500 gigawatt hours of biomethane/annum and currently employ 140 people.

Biomethane

Biomethane, a renewable alternative to natural gas, must prove its effectiveness in significantly reducing carbon emissions. This is achieved through a comprehensive life-cycle analysis that details the gas’s carbon intensity throughout its entire production cycle.

Since the feedstock for Future Biogas’s biomethane predominantly comes from purpose-grown crops, careful attention is paid to the sustainability of those crops.

To meet sustainability criteria, growers must adopt specific carbon-positive practices, such as growing cover crops, using minimum tillage and optimising the use of digestate. Farmers who meet these criteria are rewarded with a premium.

“When we are producing biomethane today, the carbon footprint of that biomethane is less than a third of the alternative fossil fuel, methane, but we are on a path to get that down to as near as zero,” Philipp said.

New services

Philipp Lukas explains that farmers are contracted to provide feedstock for the plants for a period of five to 15 years, although there are also some agreements that are renewed on a yearly basis.

While the farmer bears the risk of yield variability, they are not penalised for failing to meet contracted tonnage during years with low crop yields.

To determine the feedstock price, a calculator is used to adjust the price based on the input costs incurred by the farmer, ensuring a margin for farmers.

The biomethane gas market typically operates independently of commodity grain markets, which helps farmers to manage their risk through these contracts, explains Philipp .

A team of agronomists work closely with the farmers to discuss which crops should be grown and how they will fit into the rotation plan. The choice of crops is tailored to the specific needs of each farm. For example, an AD feedstock crop can be used to help manage problematic weeds, like blackgrass.

In such cases, the team works with the farmers to tackle the weed by introducing new crop rotations and providing guidance on control options.

Philipp believes that competition for food is not a problem, as Future Biogas’s services support farmers in developing a more sustainable food production system through expanded cropping options, improved rotations and the use of digestate as a chemical fertiliser substitute.

Philipp also believes that having an AD plant in the area offers various new services to farmers, including access to new risk management tools and local sources of farm inputs. He considers these services essential for facilitating the transition of farmers towards low carbon farming models.

Once the AD plant is constructed, it will continue to provide these services to farmers for more than 30 years.

Scale

Philipp explained that when it comes to the size of a modern AD plant, scale matters.

Due to the investment costs required in developing an AD plant capable of producing biomethane, including its construction, operation and gas connection cost, economies of scale are needed.

“Don’t think you can do this on a small scale – the diseconomies of scale are horrific,” he said.

He suggested that a minimum capacity of 30,000 to 40,000 tonnes (t) is necessary for a plant, but even larger plants, ranging from 80,000-100,000t, would offer even better economies and a reduced carbon footprint for the gas.

Phillipp Lukas, CEO of Future Biogas.

At this scale, it becomes feasible to employ feedstock managers, develop offsite feedstock clamps and use heavy goods vehicles for transporting feedstock and digestate. It also enables the production of biomethane for the unsubsidised market.

Soil carbon

All panellists agreed that rewarding farmers for improving soil health and sequestering carbon should be an integral part of farming going forward.

Philipp rewards his feedstock suppliers for carbon-friendly practices, while Neil Fuller highlighted that agriculture needs to capitalise its unique ability to absorb carbon from the atmosphere and store it; something which most other sectors can’t do.

However, this service needs to be paid for by consumers, retailers and processors, he said.

Since a significant portion of carbon emissions in food production originates from on-farm activities, it is in the interest of processors to support farm decarbonisation.

The panellists included Jan Cees Vogelaar, a co-founder of Dutch Carbon Credits, Neil Fuller, a soil scientist who works closely with UK consultancy Future Food Solution and Phillipp Lukas, CEO of UK-based Future Biogas.

Jan Cees emphasised that grassland sequesters seven times more carbon than forestry. This could be vital in developing Ireland’s grass-based AD model, they remarked.

However, Jan Cees raised concerns about accurately measuring soil carbon-level changes, emphasising the need for at least five to 10 years of data. He also questioned the actual value of these carbon credits to farmers.

Support

Developing an AD industry reliant on Government subsidies is risky, according to Jan Cees, who said he personally lost significant sums in attempting to develop AD projects in the Netherlands, waiting for support which didn’t come.

Future Biogas is one of the only companies now developing projects and selling biomethane unsubsidised to companies who need it in order to meet their sustainability goals, including AstraZeneca.

While Philipp’s company is now successfully developing projects in the absence of state support, the AD industry in the UK and across Europe could only have developed with the help of state support schemes.

If Ireland’s 2030 targets are to be achieved with only a capital grant and an obligation scheme, Philipp thinks that this will be challenging.

“Without a real kick from a subsidy regime or from an obligation regime, were going to struggle,” he said.

Next steps for Future Biogas

Future Biogas has recently been acquired by 3i Infrastructure, a FTSE 250-listed firm with a substantial portfolio worth over £3.4 billion (€3.8bn).

This acquisition provides Future Biogas with the necessary funding and support to proceed with its Project Carbon Harvest, which aims to develop and operate advanced anaerobic digestion (AD) plants that incorporate Bioenergy with Carbon Capture and Storage (BECCS) technology.

Future Biogas plans to establish BECCS sites, which will become the first in the UK to capture bio-CO2 from biogas and permanently store it underground, actively reducing carbon dioxide levels in the atmosphere.

The company’s business model is designed to operate without relying on Government subsidies.

Land use and farming practices are evolving, and it is now all but certain that carbon farming will soon become a reality.

Anaerobic digestion (AD) technology is set to play a crucial role in this transition, as highlighted by an international panel discussion during the recent launch of the Irish Farmers Journal/KPMG magazine in Kildare last week.

The panellists included Jan Cees Vogelaar, a co-founder of Dutch Carbon Credits; Neil Fuller, a soil scientist who works closely with the UK consultancy, Future Food Solution; and Philipp Lukas, CEO of UK-based Future Biogas.

Future Biogas has built and now operate 12 agricultural-based AD plants across southeast England. Over 90% of the feedstock is supplied by agricultural crops, grown by 450 farms all within 12 miles of the plants.

Founded in 2010, the company now produce 500 gigawatt hours of biomethane/annum and currently employ 140 people.

Biomethane

Biomethane, a renewable alternative to natural gas, must prove its effectiveness in significantly reducing carbon emissions. This is achieved through a comprehensive life-cycle analysis that details the gas’s carbon intensity throughout its entire production cycle.

Since the feedstock for Future Biogas’s biomethane predominantly comes from purpose-grown crops, careful attention is paid to the sustainability of those crops.

To meet sustainability criteria, growers must adopt specific carbon-positive practices, such as growing cover crops, using minimum tillage and optimising the use of digestate. Farmers who meet these criteria are rewarded with a premium.

“When we are producing biomethane today, the carbon footprint of that biomethane is less than a third of the alternative fossil fuel, methane, but we are on a path to get that down to as near as zero,” Philipp said.

New services

Philipp Lukas explains that farmers are contracted to provide feedstock for the plants for a period of five to 15 years, although there are also some agreements that are renewed on a yearly basis.

While the farmer bears the risk of yield variability, they are not penalised for failing to meet contracted tonnage during years with low crop yields.

To determine the feedstock price, a calculator is used to adjust the price based on the input costs incurred by the farmer, ensuring a margin for farmers.

The biomethane gas market typically operates independently of commodity grain markets, which helps farmers to manage their risk through these contracts, explains Philipp .

A team of agronomists work closely with the farmers to discuss which crops should be grown and how they will fit into the rotation plan. The choice of crops is tailored to the specific needs of each farm. For example, an AD feedstock crop can be used to help manage problematic weeds, like blackgrass.

In such cases, the team works with the farmers to tackle the weed by introducing new crop rotations and providing guidance on control options.

Philipp believes that competition for food is not a problem, as Future Biogas’s services support farmers in developing a more sustainable food production system through expanded cropping options, improved rotations and the use of digestate as a chemical fertiliser substitute.

Philipp also believes that having an AD plant in the area offers various new services to farmers, including access to new risk management tools and local sources of farm inputs. He considers these services essential for facilitating the transition of farmers towards low carbon farming models.

Once the AD plant is constructed, it will continue to provide these services to farmers for more than 30 years.

Scale

Philipp explained that when it comes to the size of a modern AD plant, scale matters.

Due to the investment costs required in developing an AD plant capable of producing biomethane, including its construction, operation and gas connection cost, economies of scale are needed.

“Don’t think you can do this on a small scale – the diseconomies of scale are horrific,” he said.

He suggested that a minimum capacity of 30,000 to 40,000 tonnes (t) is necessary for a plant, but even larger plants, ranging from 80,000-100,000t, would offer even better economies and a reduced carbon footprint for the gas.

Phillipp Lukas, CEO of Future Biogas.

At this scale, it becomes feasible to employ feedstock managers, develop offsite feedstock clamps and use heavy goods vehicles for transporting feedstock and digestate. It also enables the production of biomethane for the unsubsidised market.

Soil carbon

All panellists agreed that rewarding farmers for improving soil health and sequestering carbon should be an integral part of farming going forward.

Philipp rewards his feedstock suppliers for carbon-friendly practices, while Neil Fuller highlighted that agriculture needs to capitalise its unique ability to absorb carbon from the atmosphere and store it; something which most other sectors can’t do.

However, this service needs to be paid for by consumers, retailers and processors, he said.

Since a significant portion of carbon emissions in food production originates from on-farm activities, it is in the interest of processors to support farm decarbonisation.

The panellists included Jan Cees Vogelaar, a co-founder of Dutch Carbon Credits, Neil Fuller, a soil scientist who works closely with UK consultancy Future Food Solution and Phillipp Lukas, CEO of UK-based Future Biogas.

Jan Cees emphasised that grassland sequesters seven times more carbon than forestry. This could be vital in developing Ireland’s grass-based AD model, they remarked.

However, Jan Cees raised concerns about accurately measuring soil carbon-level changes, emphasising the need for at least five to 10 years of data. He also questioned the actual value of these carbon credits to farmers.

Support

Developing an AD industry reliant on Government subsidies is risky, according to Jan Cees, who said he personally lost significant sums in attempting to develop AD projects in the Netherlands, waiting for support which didn’t come.

Future Biogas is one of the only companies now developing projects and selling biomethane unsubsidised to companies who need it in order to meet their sustainability goals, including AstraZeneca.

While Philipp’s company is now successfully developing projects in the absence of state support, the AD industry in the UK and across Europe could only have developed with the help of state support schemes.

If Ireland’s 2030 targets are to be achieved with only a capital grant and an obligation scheme, Philipp thinks that this will be challenging.

“Without a real kick from a subsidy regime or from an obligation regime, were going to struggle,” he said.

Next steps for Future Biogas

Future Biogas has recently been acquired by 3i Infrastructure, a FTSE 250-listed firm with a substantial portfolio worth over £3.4 billion (€3.8bn).

This acquisition provides Future Biogas with the necessary funding and support to proceed with its Project Carbon Harvest, which aims to develop and operate advanced anaerobic digestion (AD) plants that incorporate Bioenergy with Carbon Capture and Storage (BECCS) technology.

Future Biogas plans to establish BECCS sites, which will become the first in the UK to capture bio-CO2 from biogas and permanently store it underground, actively reducing carbon dioxide levels in the atmosphere.

The company’s business model is designed to operate without relying on Government subsidies.

SHARING OPTIONS